9

Italiano

AGLLRIJ 0907 - 4528560_03

INSTALLAZIONE "GLL20R"

- Aprire l'imballo dell'accessorio assie-

me cornice di mandata e griglia d’aspi-

razione, togliere la griglia dall'imballo

e controllare che non sia stata danneg-

giata durante il trasporto.

- Aprire il coperchio della morsettiera

sulla scatola elettrica, per sbloccare i

ganci a pressione usare un utensile.

- Collegare i cavi di alimentazione alla

morsettiera come indicato nello sche-

ma elettrico.

- Fissare tutti i cavi con il bloccacavo.

- Richiudere il coperchio della morset-

tiera elettrica.

- Verificare ed eventualmente resetta-

re i Dip-Switch sulla scatola elettrica

secondo le funzioni desiderate. (Vedi

tabella delle impostazioni)

- Inserire la scatola elettrica nella guida

dell'unità FCL ed assicurarsi che i con-

nettori siano ben collegati.

- La scatola elettrica va fissata all'unità

FCL con due viti.

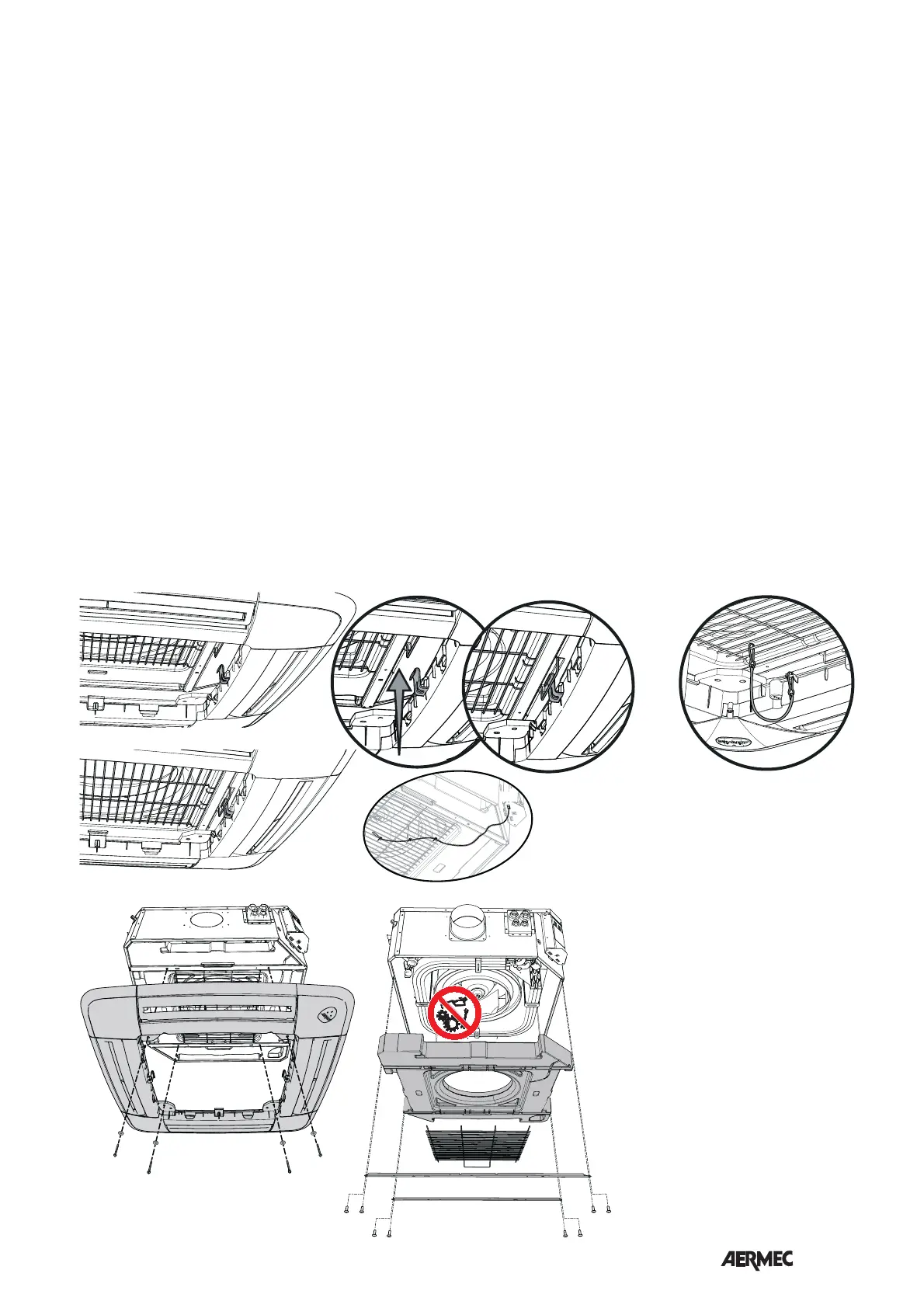

- Applicare la sonda aria (SA) al centro

della griglia del ventilatore, fissare il

cavo con le fascette a corredo, stende-

re il cavo in eccesso negli incavi rica-

vati nel polistirolo.

- Collegare la sonda SA al connettore

sulla scatola elettrica.

- Togliere la griglia di aspirazione agen-

do sui 2 nottolini ad un ¼ di giro.

- Appendere la cornice ai due ganci di

sostegno, fare attenzione alla posizio-

ne di montaggio, l'angolo della corni-

ce il vetrino con il logo AERMEC deve

coincidere con l'angolo della scatola

elettrica dell'unità FCL.

- ATTENZIONE: fissare un moschetto-

ne del cavetto di sicurezza al tela-

io griglia e l'altro moschettone alla

griglia di protezione del ventilatore.

- Montare l'adattore (a corredo) al cavo

del ricevitore .

- Collegare il cavo di collegamento del

ricevitore al connettore sulla scatola

della scheda elettronica.

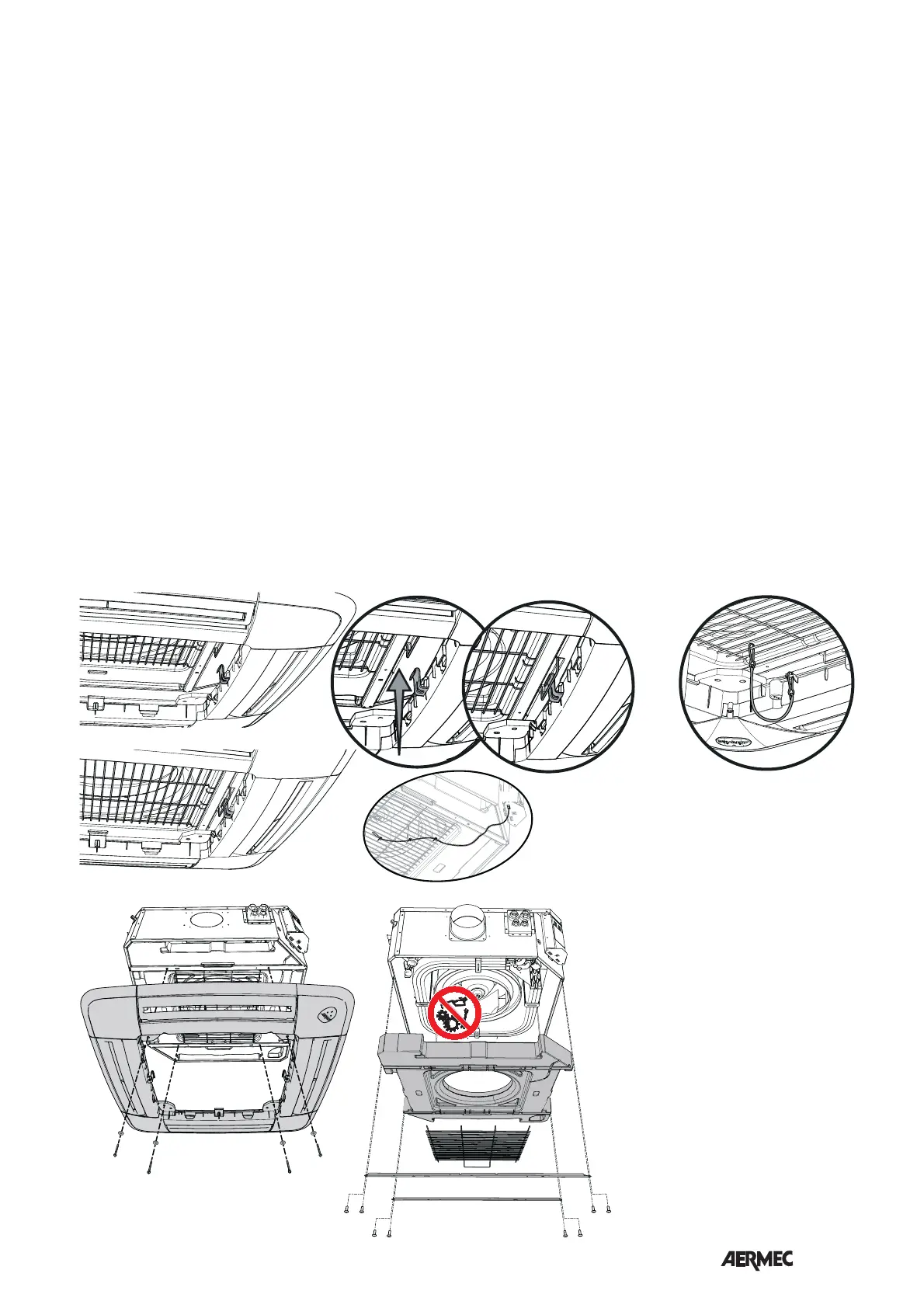

- Fissare la cornice all’unità tramite le 4

viti a corredo.

ATTENZIONE!! avvitare le viti con

una coppia di serraggio massima di

0,45 Nm, si consiglia di utilizzare un

cacciavite, non usare avvitatori non

tarati. Una eccessiva coppia di ser-

raggio provoca danni irreversibili alla

bacinella.

La cornice garantisce la tenuta tra aspi-

razione e mandata dell’aria, pertan-

to deve essere fissata correttamente

all’unità senza subire deformazioni.

- Assicurare la griglia di aspirazione al

cavetto di sicurezza.

- Montare la griglia di aspirazione

agganciandola alla cerniera sulla cor-

nice.

- Richiudere la griglia di aspirazione e

avvitare i due nottolini (sul lato oppo-

sto alla cerniera) di un ¼ di giro.

- Registrare la posizione dell’unità dalla

staffa di supporto mediante i dadi, in

modo che l’unità sia in bolla e la cor-

nice appoggi leggermente nel contro-

soffitto.

- Inserire le batterie in dotazione nel

telecomando.

- Avviare il ventilconvettore ed eseguire

una prova di funzionamento, le funzio-

ni sono descritte nel manuale d’uso.

Manutenzione scatola elettrica

In caso si rendesse necessario accedere

alla scatola elettrica per manutenzioni

o per resettare i Dip Switch, seguire le

seguenti indicazioni:

- Aprire la griglia filtro (ruotare i 2 notto-

lini di un ¼ di giro).

- Togliere la vite di bloccaggio dello

sportello d'angolo con il logo Aermec.

- Togliere le 2 viti di bloccaggio della

scatola elettrica.

- Sfilare verso il basso la scatola elettrica.

- Eseguire le manutenzioni necessarie

necessarie.

- Rimontare il tutto seguendo la proce-

dura inversa allo smontaggio.

SA

• Smontaggio per manutenzione

- Prima di eseguire qualsiasi operazione

sull'unità è obbligatorio interrompere

l'alimentazione elettrica.

- Per accedere all'interno dell'unità

rimuovere i due traversini fissati con

le viti al telaio. Sarà quindi possibile

rimuovere la griglia di protezione del

ventilatore e la bacinella in polistirolo.

(vedi figura)

- PERICOLO!!. Prima di ridare tensione

all'unità è obbligatorio aver rimontato

correttamente tutti i componenti ed in

paticolare la griglia di protezione.

Loading...

Loading...