9

---°C

100.0%

100.0%

100.0%Circuit 2:

Circuit 1:

Total require

Common Outlet:

— Common output (optional): probe water temperature on the common output

of the two master and slave unit outputs;

— Demand: power calculated by the Master unit thermostat that will be distribut-

ed between the two units;

— Unit 1: percentage power requested of the Master unit;

— Unit 2: percentage power requested of the Slave unit;

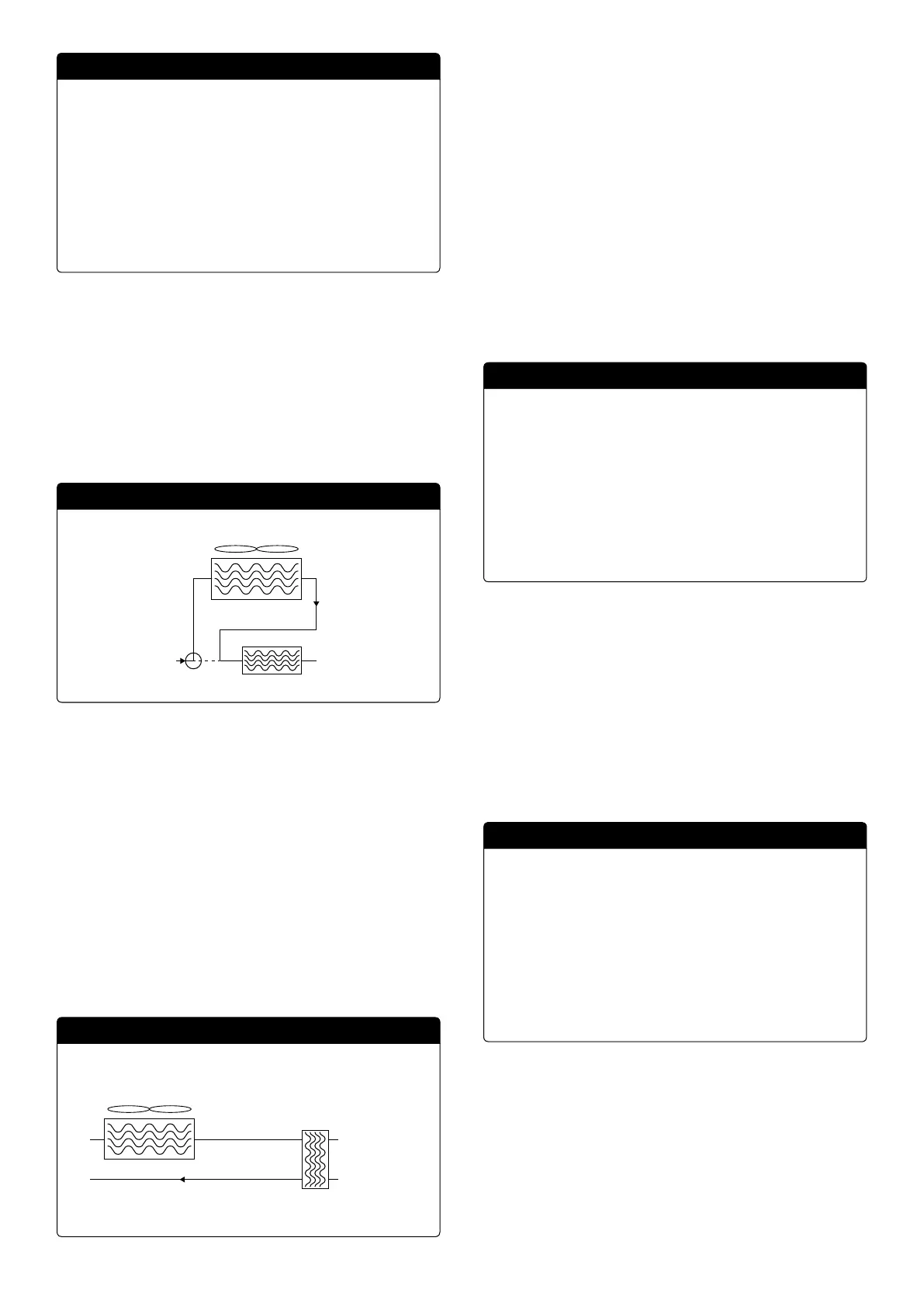

2.6 FREE COOLING MONITOR

WARNING: this mask is available on free cooling units.

This mask is used to display the status of the free cooling circuit:

FC

38%

14.2°C 10.0°C

0/092%

15.0°C

Potenza FC:

Tot:

— Activation of the 3-way valve with the display of moving arrows for pump status

and water circulation;

— Power delivered by the free cooling based on that available;

— Operating status;

— Tot: total power as a percentage delivered by the unit. If only free cooling, corre-

sponds to the total power delivered by free cooling, if mixed operation the total

power is the sum of the power delivered by free cooling and the compressors;

— Display of the values of the free cooling input (lower left), evaporator input (if FC

on, upper right) and evaporator output (lower right) probes;

Possible operating status:

— OFF (unit o );

— FC (unit only operating in free cooling);

— FC+CP (unit in mixed operation);

— CP (unit operating with compressors only);

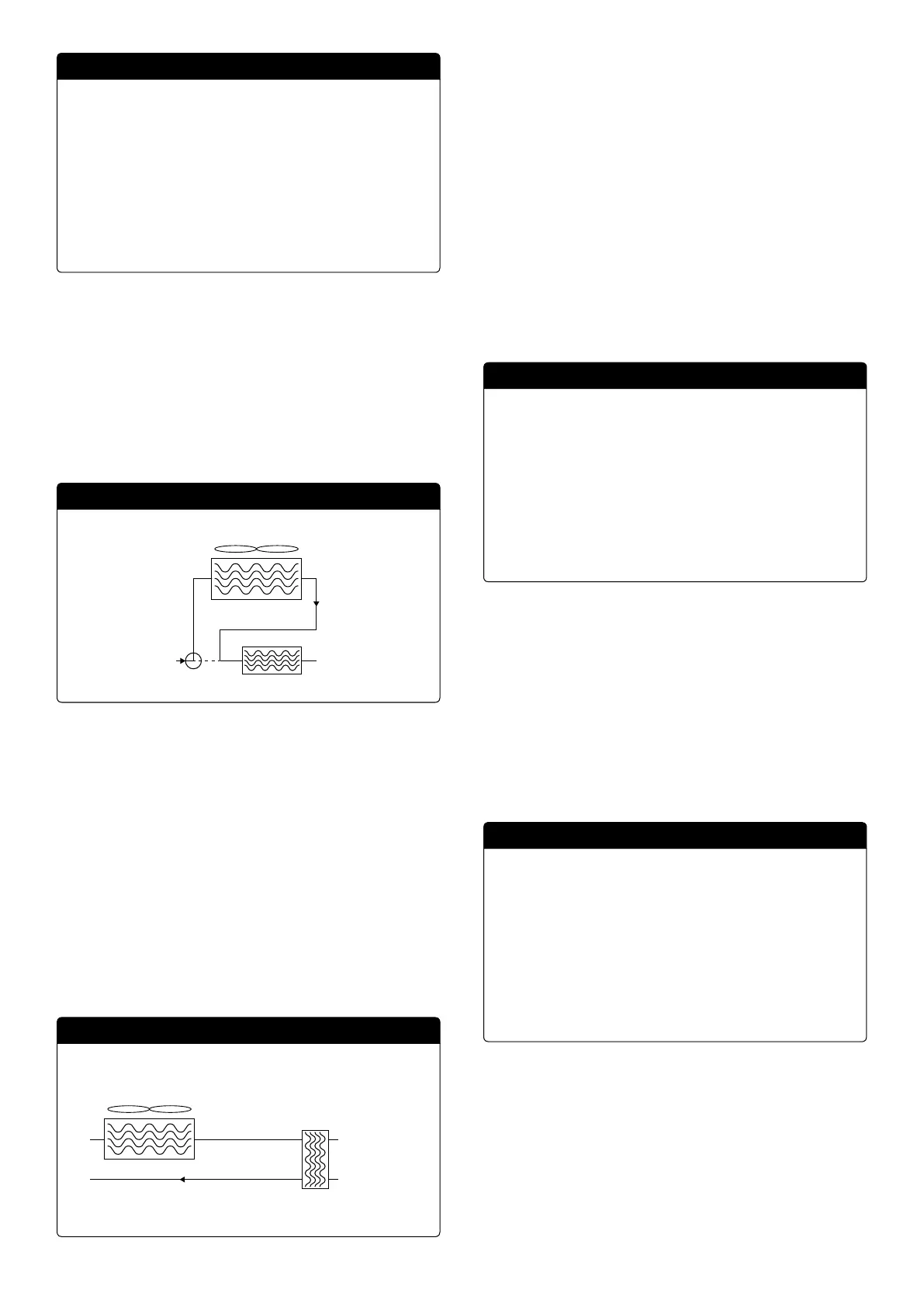

2.7 GLYCOLFREE MONITOR

WARNING: this mask is available on glycolfree units.

This mask is used to display the status of the glycolfree circuit:

FC

41/094%

41%

14.7°C

14.2°C

14.1°C

15.0°C

Potenza FC:

Totale:

— Activation of the branch containing glycol with the display of moving arrows for

pump status and water circulation;

— Power delivered by the free cooling based on that available;

— Tot: total power as a percentage delivered by the unit. If only free cooling, corre-

sponds to the total power delivered by free cooling, if mixed operation the total

power is the sum of the power delivered by free cooling and the compressors;

— Display of the values of the free cooling output (upper left), free cooling input

(lower left), intermediate evaporator (upper right) and evaporator input (lower

right) probes;

— Operating status;

Possible operating status:

— OFF (unit o );

— FC (unit only operating in free cooling);

— FC+CP (unit in mixed operation);

— CP (unit operating with compressors only);

2.8 TOTAL RECOVERY MONITOR

WARNING: this mask is available on units with total recovery.

This mask is used to display the status of the total recovery:

42.2°C

43.8°C

0%

Ingresso acqua:

Uscita acqua:

O generale

Richiesta:

— Display of the water temperature value of the total recovery input probe;

— Display of the water temperature value of the total recovery output probe;

Total recovery status:

— ow switch open (water is not circulating in the hydraulic circuit of the recovery

system and therefore it is disabled);

— enabled (water is circulating in the hydraulic circuit of the recovery system and

therefore it is enabled);

— general o (the whole unit is in stand-by), o from the display (general disa-

bling of the unit from the pGD1 button);

2.9 PEC PRESSURE CONTROL MONITOR

This mask is used to display the result of the control on the machine pressure delta,

controlled by the PEC card:

:

in progress...

Pressure delta control

PEC

If the result of the pressure delta control is greater than 15 bar (and the 4-way must

switch), the valves must be controlled without the activation of the compressors to

reduce the pressure delta; Alarms (warnings) are not generated in this situation).

If the control is less than 3 bar (hot/cold operation or a 4-way must switch), the

compressors are started without the valve control in order to create the pressure

delta; after 300s in this situation an alarm is generated with a machine block.

Loading...

Loading...