27

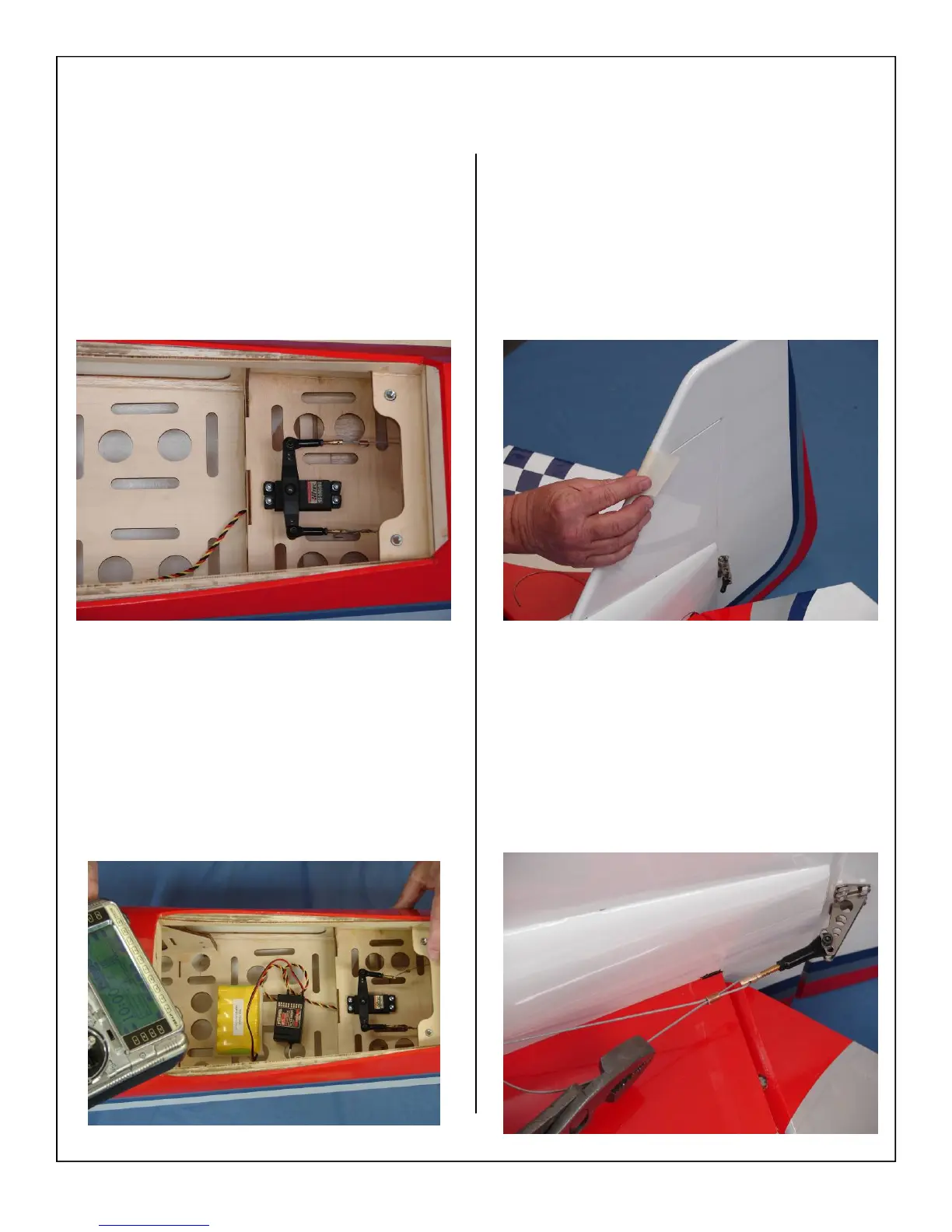

11. Attach the ball links and brass spacers to the

rudder servo arm and then attach the servo arm

to the rudder servo as shown.

12. Plug the rudder servo into the rudder channel of

the receiver and power up. Turn on transmitter

to center rudder servo. Ensure servo trim and

sub trims are centered.

Note: On metal geared servos use Loctite for all

Servo arm mounting screws.

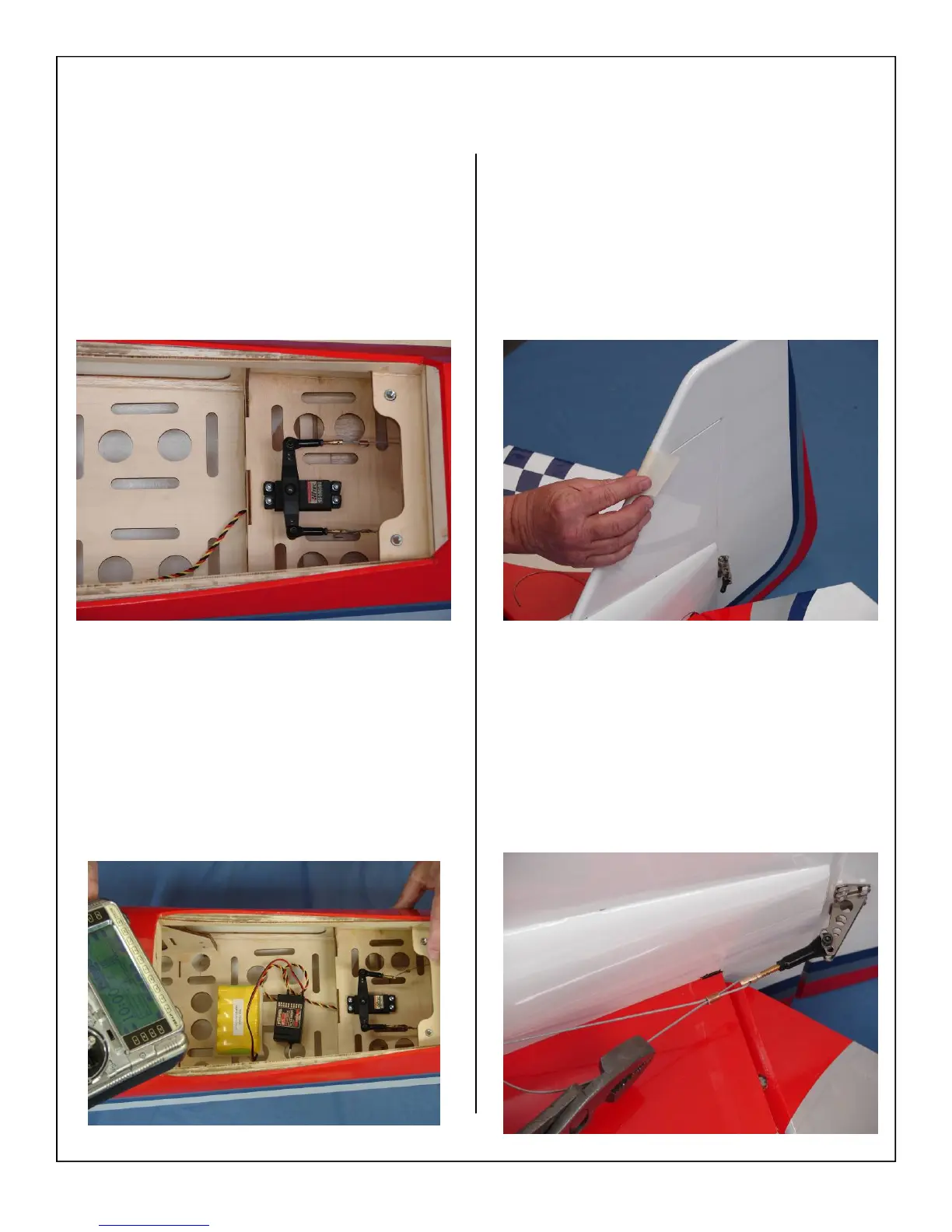

13. Tape the rudder balance tab to the top leading

edge of the vertical fin in the neutral position as

shown. This ensures the rudder is straight when

the cables are attached.

14. Screw threaded couplers half way into ball links.

Attach ball link to rudder control horn on both

sides of the rudder. Thread the rudder cable

through a brass swage tube, then the threaded

coupler, and back through the brass swage tube

on both sides. Pull with light tension on the ca-

ble through the coupler on both sides as shown.

The loop through the coupler should be approxi-

mately 1/2” long.

Loading...

Loading...