AHT Cooling Systems GmbH

14. What to do if…

ATTENTION: Work on the electrical system and

refrigeration system may only be performed by

specialists.

The performance and safety of the unit has been care-

fully tested in the AHT test centre. Nevertheless, should

a fault arise, please first check the following:

• Is the power plug plugged in?

• Is the unit switched on (see Chapter 8 (On/Off

switch))?

• Is the socket live?

• Is the display active?

• Lamp does not illuminate – switch on the lighting

with the light switch (see Chapter 8).

If the fault is not caused by any of these, please call

your customer service / service partner.

15. Exploded View Drawings and Parts Lists

Exploded view drawings and parts lists are available to

service partners.

GB

DECLARATION OF CONFORMITY

The manufacturer

AHT Cooling Systems GmbH

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA

Directives 2004/108/EC and 2006/95/EC.

The valid versions of the following standards were applied to the design and construction of the machines: EN 378:2008; EN ISO 23953:2005;

EN 60335-1:2002 + A11:2004 + A1:2004 + A12:2006 + A13:2008; EN 60335-2-89:2002 + A11:2004 + A1:2005; EN 50366:2003 + A1:2006; EN

55014-1:2000 + A1:2001 + A2:2002; EN 55014-2:1997 + A1:2001; EN 55015:2006; EN 61000-3-2:2006; EN 61000-3-3:1995 +A1:2001 +

Additionally for PROPAN R290 equipment: IEC / EN 60079-15:2005

Rottenmann, 06.02.2009

A2:2005; EN 61000-3-11:2000

Rottenmann, 17.12.2009

Techn. Geschäftsführer

Chief operating of

Direction technique

Entwicklungsleiter

R & D Manager

Responsable recherche

et développement

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA Directives

2004/108/EG and 2006/42/EG.

16. Konformitätserklärung / Declaration of Conformity

• Change the absorption cloth in the condensate basin

• Plug the unit back in and allow it to run for 2 hours.

• Replace products

11. Taking the unit out of operation for

extended periods

• Move all products elsewhere.

• Unplug from the mains.

• Clean the unit

• If you are changing the location, adjust the height of

the levelling feet (see Chapter 5).

12. Changing the Lamp

13. Disposal

ATTENTION: Thermal insulation material

EPS

Do

not put the unit in with regular waste.

Please check your obligations in accordance

with the national WEEE provisions and the lo-

cal WEEE disposal partner. Ensure that the

piping is not damaged in the process.

AHT Cooling Systems GmbH

14. What to do if…

ATTENTION: Work on the electrical system and

refrigeration system may only be performed by

specialists.

The performance and safety of the unit has been care-

fully tested in the AHT test centre. Nevertheless, should

a fault arise, please first check the following:

• Is the power plug plugged in?

• Is the unit switched on (see Chapter 8 (On/Off

switch))?

• Is the socket live?

• Is the display active?

• Lamp does not illuminate – switch on the lighting

with the light switch (see Chapter 8).

If the fault is not caused by any of these, please call

your customer service / service partner.

15. Exploded View Drawings and Parts Lists

Exploded view drawings and parts lists are available to

service partners.

GB

DECLARATION OF CONFORMITY

The manufacturer

AHT Cooling Systems GmbH

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA

Directives 2004/108/EC and 2006/95/EC.

The valid versions of the following standards were applied to the design and construction of the machines: EN 378:2008; EN ISO 23953:2005;

EN 60335-1:2002 + A11:2004 + A1:2004 + A12:2006 + A13:2008; EN 60335-2-89:2002 + A11:2004 + A1:2005; EN 50366:2003 + A1:2006; EN

55014-1:2000 + A1:2001 + A2:2002; EN 55014-2:1997 + A1:2001; EN 55015:2006; EN 61000-3-2:2006; EN 61000-3-3:1995 +A1:2001 +

Additionally for PROPAN R290 equipment: IEC / EN 60079-15:2005

Rottenmann, 06.02.2009

A2:2005; EN 61000-3-11:2000

Rottenmann, 17.12.2009

Techn. Geschäftsführer

Chief operating of

Direction technique

Entwicklungsleiter

R & D Manager

Responsable recherche

et développement

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA Directives

2004/108/EG and 2006/42/EG.

16. Konformitätserklärung / Declaration of Conformity

• Change the absorption cloth in the condensate basin

• Plug the unit back in and allow it to run for 2 hours.

• Replace products

11. Taking the unit out of operation for

extended periods

• Move all products elsewhere.

• Unplug from the mains.

• Clean the unit

• If you are changing the location, adjust the height of

the levelling feet (see Chapter 5).

12. Changing the Lamp

13. Disposal

ATTENTION: Thermal insulation material

EPS

Do

not put the unit in with regular waste.

Please check your obligations in accordance

with the national WEEE provisions and the lo-

cal WEEE disposal partner. Ensure that the

piping is not damaged in the process.

Werksgasse 57

8786 Rottenmann, Austria

Changing lamps (replacing the uorescent tubes or LED

lamps) may only be carried out by a qualied electrician

or authorised specialist.

ATTENTION: if a lamp breaks, carefully remove all the

broken glass from the stacking area.

CE-Bevollmächtigter: Thomas Mayr, Abteilung Entwicklung;

AHT Cooling Systems GmbH, Werkgasse 57,8786 Rottenmann

Additionally PROPAN R290 Geräte: IEC / EN 60079-15:2010

Rottenmann, 03.10.2011

13

AHT Cooling Systems GmbH

14. What to do if…

ATTENTION: Work on the electrical system and

refrigeration system may only be performed by

specialists.

The performance and safety of the unit has been care-

fully tested in the AHT test centre. Nevertheless, should

a fault arise, please first check the following:

• Is the power plug plugged in?

• Is the unit switched on (see Chapter 8 (On/Off

switch))?

• Is the socket live?

• Is the display active?

• Lamp does not illuminate – switch on the lighting

with the light switch (see Chapter 8).

If the fault is not caused by any of these, please call

your customer service / service partner.

15. Exploded View Drawings and Parts Lists

Exploded view drawings and parts lists are available to

service partners.

GB

DECLARATION OF CONFORMITY

The manufacturer

AHT Cooling Systems GmbH

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA

Directives 2004/108/EC and 2006/95/EC.

The valid versions of the following standards were applied to the design and construction of the machines: EN 378:2008; EN ISO 23953:2005;

EN 60335-1:2002 + A11:2004 + A1:2004 + A12:2006 + A13:2008; EN 60335-2-89:2002 + A11:2004 + A1:2005; EN 50366:2003 + A1:2006; EN

55014-1:2000 + A1:2001 + A2:2002; EN 55014-2:1997 + A1:2001; EN 55015:2006; EN 61000-3-2:2006; EN 61000-3-3:1995 +A1:2001 +

Additionally for PROPAN R290 equipment: IEC / EN 60079-15:2005

Rottenmann, 06.02.2009

A2:2005; EN 61000-3-11:2000

Rottenmann, 17.12.2009

Techn. Geschäftsführer

Chief operating of

Direction technique

Entwicklungsleiter

R & D Manager

Responsable recherche

et développement

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA Directives

2004/108/EG and 2006/42/EG.

16. Konformitätserklärung / Declaration of Conformity

• Change the absorption cloth in the condensate basin

• Plug the unit back in and allow it to run for 2 hours.

• Replace products

11. Taking the unit out of operation for

extended periods

• Move all products elsewhere.

• Unplug from the mains.

• Clean the unit

• If you are changing the location, adjust the height of

the levelling feet (see Chapter 5).

12. Changing the Lamp

13. Disposal

ATTENTION: Thermal insulation material

EPS

Do

not put the unit in with regular waste.

Please check your obligations in accordance

with the national WEEE provisions and the lo-

cal WEEE disposal partner. Ensure that the

piping is not damaged in the process.

Changing lamps (replacing the uorescent tubes or LED

lamps) may only be carried out by a qualied electrician

or authorised specialist.

ATTENTION: if a lamp breaks, carefully remove all the

broken glass from the stacking area.

13

AHT Cooling Systems GmbH

14. What to do if…

ATTENTION: Work on the electrical system and

refrigeration system may only be performed by

specialists.

The performance and safety of the unit has been care-

fully tested in the AHT test centre. Nevertheless, should

a fault arise, please first check the following:

• Is the power plug plugged in?

• Is the unit switched on (see Chapter 8 (On/Off

switch))?

• Is the socket live?

• Is the display active?

• Lamp does not illuminate – switch on the lighting

with the light switch (see Chapter 8).

If the fault is not caused by any of these, please call

your customer service / service partner.

15. Exploded View Drawings and Parts Lists

Exploded view drawings and parts lists are available to

service partners.

GB

DECLARATION OF CONFORMITY

The manufacturer

AHT Cooling Systems GmbH

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA

Directives 2004/108/EC and 2006/95/EC.

The valid versions of the following standards were applied to the design and construction of the machines: EN 378:2008; EN ISO 23953:2005;

EN 60335-1:2002 + A11:2004 + A1:2004 + A12:2006 + A13:2008; EN 60335-2-89:2002 + A11:2004 + A1:2005; EN 50366:2003 + A1:2006; EN

55014-1:2000 + A1:2001 + A2:2002; EN 55014-2:1997 + A1:2001; EN 55015:2006; EN 61000-3-2:2006; EN 61000-3-3:1995 +A1:2001 +

Additionally for PROPAN R290 equipment: IEC / EN 60079-15:2005

Rottenmann, 06.02.2009

A2:2005; EN 61000-3-11:2000

Rottenmann, 17.12.2009

Techn. Geschäftsführer

Chief operating of

Direction technique

Entwicklungsleiter

R & D Manager

Responsable recherche

et développement

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA Directives

2004/108/EG and 2006/42/EG.

16. Konformitätserklärung / Declaration of Conformity

• Change the absorption cloth in the condensate basin

• Plug the unit back in and allow it to run for 2 hours.

• Replace products

11. Taking the unit out of operation for

extended periods

• Move all products elsewhere.

• Unplug from the mains.

• Clean the unit

• If you are changing the location, adjust the height of

the levelling feet (see Chapter 5).

12. Changing the Lamp

13. Disposal

ATTENTION: Thermal insulation material

EPS

Do

not put the unit in with regular waste.

Please check your obligations in accordance

with the national WEEE provisions and the lo-

cal WEEE disposal partner. Ensure that the

piping is not damaged in the process.

Heat insulation material

13

AHT Cooling Systems GmbH

14. What to do if…

ATTENTION: Work on the electrical system and

refrigeration system may only be performed by

specialists.

The performance and safety of the unit has been care-

fully tested in the AHT test centre. Nevertheless, should

a fault arise, please first check the following:

• Is the power plug plugged in?

• Is the unit switched on (see Chapter 8 (On/Off

switch))?

• Is the socket live?

• Is the display active?

• Lamp does not illuminate – switch on the lighting

with the light switch (see Chapter 8).

If the fault is not caused by any of these, please call

your customer service / service partner.

15. Exploded View Drawings and Parts Lists

Exploded view drawings and parts lists are available to

service partners.

GB

DECLARATION OF CONFORMITY

The manufacturer

AHT Cooling Systems GmbH

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA

Directives 2004/108/EC and 2006/95/EC.

The valid versions of the following standards were applied to the design and construction of the machines: EN 378:2008; EN ISO 23953:2005;

EN 60335-1:2002 + A11:2004 + A1:2004 + A12:2006 + A13:2008; EN 60335-2-89:2002 + A11:2004 + A1:2005; EN 50366:2003 + A1:2006; EN

55014-1:2000 + A1:2001 + A2:2002; EN 55014-2:1997 + A1:2001; EN 55015:2006; EN 61000-3-2:2006; EN 61000-3-3:1995 +A1:2001 +

Additionally for PROPAN R290 equipment: IEC / EN 60079-15:2005

Rottenmann, 06.02.2009

A2:2005; EN 61000-3-11:2000

Rottenmann, 17.12.2009

Techn. Geschäftsführer

Chief operating of

Direction technique

Entwicklungsleiter

R & D Manager

Responsable recherche

et développement

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA Directives

2004/108/EG and 2006/42/EG.

16. Konformitätserklärung / Declaration of Conformity

• Change the absorption cloth in the condensate basin

• Plug the unit back in and allow it to run for 2 hours.

• Replace products

11. Taking the unit out of operation for

extended periods

• Move all products elsewhere.

• Unplug from the mains.

• Clean the unit

• If you are changing the location, adjust the height of

the levelling feet (see Chapter 5).

12. Changing the Lamp

13. Disposal

ATTENTION: Thermal insulation material

EPS

Do

not put the unit in with regular waste.

Please check your obligations in accordance

with the national WEEE provisions and the lo-

cal WEEE disposal partner. Ensure that the

piping is not damaged in the process.

AHT Cooling Systems GmbH

14. What to do if…

ATTENTION: Work on the electrical system and

refrigeration system may only be performed by

specialists.

The performance and safety of the unit has been care-

fully tested in the AHT test centre. Nevertheless, should

a fault arise, please first check the following:

• Is the power plug plugged in?

• Is the unit switched on (see Chapter 8 (On/Off

switch))?

• Is the socket live?

• Is the display active?

• Lamp does not illuminate – switch on the lighting

with the light switch (see Chapter 8).

If the fault is not caused by any of these, please call

your customer service / service partner.

15. Exploded View Drawings and Parts Lists

Exploded view drawings and parts lists are available to

service partners.

GB

DECLARATION OF CONFORMITY

The manufacturer

AHT Cooling Systems GmbH

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA

Directives 2004/108/EC and 2006/95/EC.

The valid versions of the following standards were applied to the design and construction of the machines: EN 378:2008; EN ISO 23953:2005;

EN 60335-1:2002 + A11:2004 + A1:2004 + A12:2006 + A13:2008; EN 60335-2-89:2002 + A11:2004 + A1:2005; EN 50366:2003 + A1:2006; EN

55014-1:2000 + A1:2001 + A2:2002; EN 55014-2:1997 + A1:2001; EN 55015:2006; EN 61000-3-2:2006; EN 61000-3-3:1995 +A1:2001 +

Additionally for PROPAN R290 equipment: IEC / EN 60079-15:2005

Rottenmann, 06.02.2009

A2:2005; EN 61000-3-11:2000

Rottenmann, 17.12.2009

Techn. Geschäftsführer

Chief operating of

Direction technique

Entwicklungsleiter

R & D Manager

Responsable recherche

et développement

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA Directives

2004/108/EG and 2006/42/EG.

16. Konformitätserklärung / Declaration of Conformity

• Change the absorption cloth in the condensate basin

• Plug the unit back in and allow it to run for 2 hours.

• Replace products

11. Taking the unit out of operation for

extended periods

• Move all products elsewhere.

• Unplug from the mains.

• Clean the unit

• If you are changing the location, adjust the height of

the levelling feet (see Chapter 5).

12. Changing the Lamp

13. Disposal

ATTENTION: Thermal insulation material

EPS

Do

not put the unit in with regular waste.

Please check your obligations in accordance

with the national WEEE provisions and the lo-

cal WEEE disposal partner. Ensure that the

piping is not damaged in the process.

AHT Cooling Systems GmbH

4

• Verzichten Sie auf grobe oder leicht entzündliche

Reinigungsprodukte, um Schäden zu vermeiden.

• Flächen und vorderes Lüftungsgitter mit einem

feuchten, sauberen Tuch und mit neutraler Seife

reinigen. Verwenden Sie zur Reinigung keine

scharfen Gegenstände.

• Reinigung der herausgenommenen Regalböden mit

feuchtem, sauberen Tuch und neutraler Seife.

• Reinigung der Glasflächen mit Glasreiniger

• Trocknen Sie das Gerät und Regalböden mit einem

Tuch

• Bei Bedarf Regalböden einlegen

• Netzstecker einstecken und 2 Std. laufen lassen.

• Waren einlagern

Die mindestens jährlich durchzuführende

Hauptreinigung, ist ausschließlich durch den

autorisierten Servicetechniker durchzuführen!

Limpeza do espaço interior da área dos ventiladores

• Levantar a grelha interna (chapa do compartimento

do fundo)

• Puxar a grelha interna para trás, em direcção ao

espaço interior

• Se necessário, limpar o espaço interior dos

ventiladores

• Secar o espaço interior com um pano.

• Inserir a grelha interna, empurrando-a para a frente, e

engatá-la no compartimento do fundo

11. Längere Außerbetriebnahme des Gerätes

• Alle Waren auslagern

• Netzstecker ziehen

• Reinigung des Geräts gemäß Grund- und

Hauptreinigung

• Bei Ortsveränderung Höhenverstellung der Stellfüße

(siehe Kap. 5).

12. Lampenwechsel

Der Lampenwechsel (Tausch der Leuchtstoffröhren/

LED-Leuchten) darf nur durch eine autorisierte

Fachkraft erfolgen!

ACHTUNG: Bei Lampenbruch Glasteile sorgfältig

aus dem Warenraum entfernen.

13. Entsorgung

ACHTUNG: Wärmedämmstoff Espuma de

poliuretano (PU) com dióxido de carbono

Das Gerät nicht zum normalen Müll, sondern

prüfen Sie bitte Ihre Verpflichtungen gemäß

den nationalen WEEE-Bestimmungen und

dem örtlichen

WEEE-

Entsorgungspartner

. Darauf achten, dass

dabei die Rohrleitungen nicht beschädigt

werden.

14. Was tun wenn ...

ACHTUNG: Arbeiten an der elektrischen Anlage und

am Kältesystem dürfen nur von Fachkräften

durchgeführt werden.

Das Gerät wurde im AHT - Prüfzentrum sorgfältig auf

Leistung und Sicherheit geprüft. Sollte trotzdem einmal

eine Störung auftreten, überprüfen Sie bitte zunächst

folgendes:

• Ist der Netzstecker eingesteckt?

• Ist das Gerät eingeschaltet (siehe Kap. 8 - Drücken

der Standby-Taste)?

• Liegt Spannung an der Steckdose an?

• Ist die Anzeige aktiv?

• Lampe leuchtet nicht (siehe Kap.8 - Drücken der

Licht-Taste).

Beruht die Störung auf keiner dieser Ursachen, Anruf

beim Kundendienst / Servicepartner.

15. Explosionszeichungen und Teileliste

Explosionszeichnungen und Teilelisten liegen den

Servicepartnern vor.

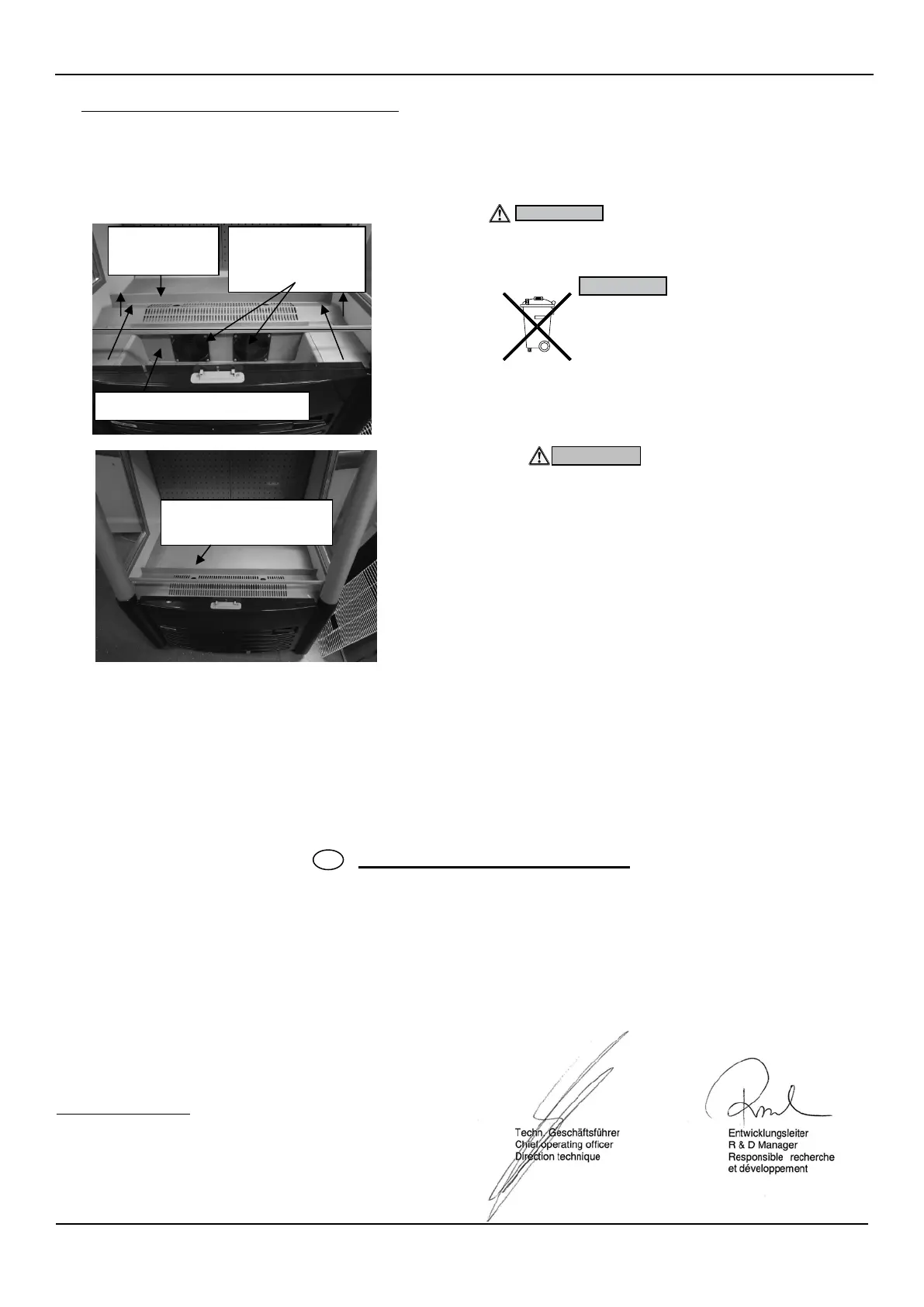

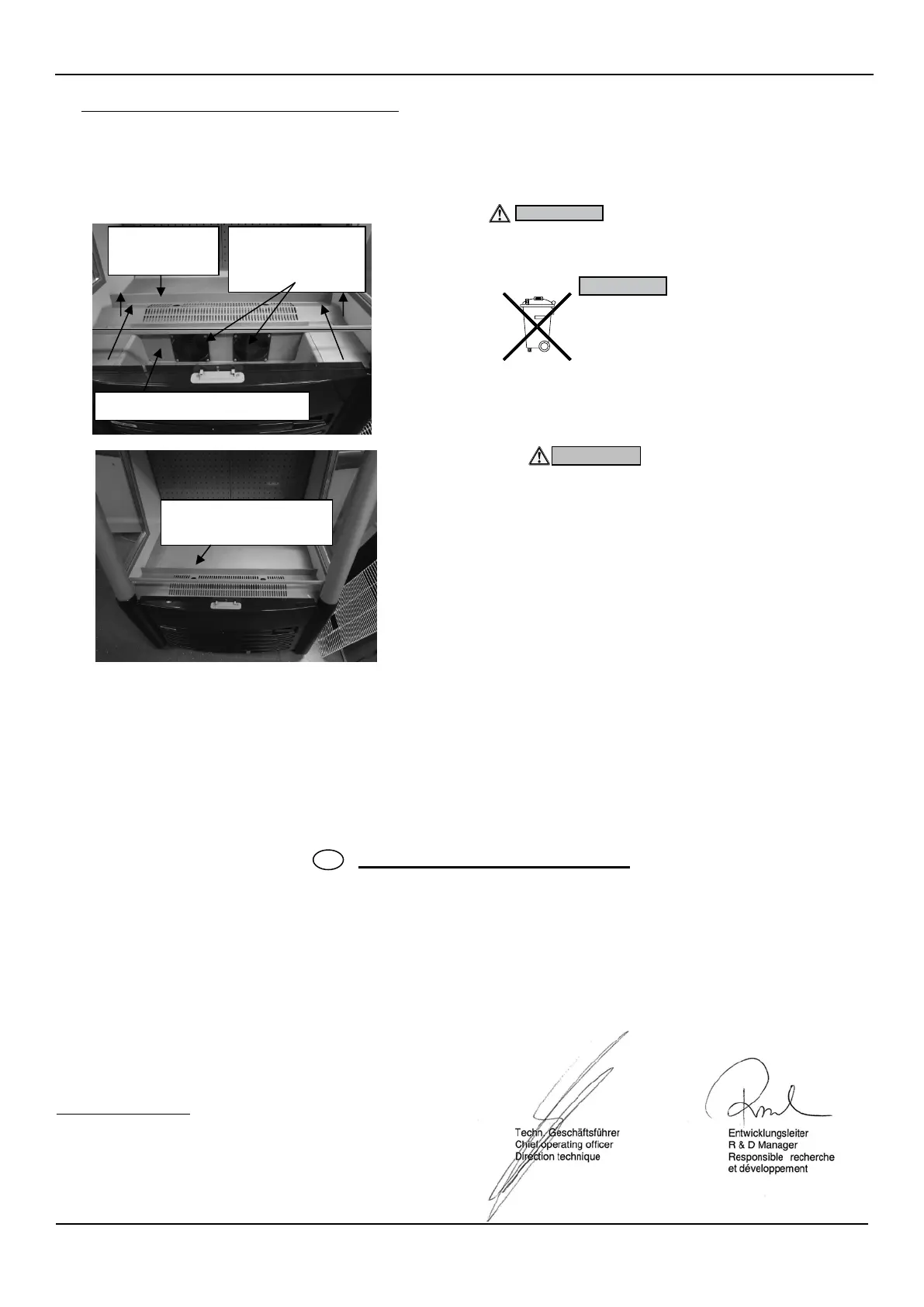

Cleaning the interior fan area (optional)

• Lift the interior grille

• Pull back the interior grille

• If required clean the interior fan space with a cloth

• Rex the inner grill

Removable

interior grille

Fan space closed

Protective fan

cover

Fan space open

AHT Cooling Systems GmbH

14. What to do if…

ATTENTION: Work on the electrical system and

refrigeration system may only be performed by

specialists.

The performance and safety of the unit has been care-

fully tested in the AHT test centre. Nevertheless, should

a fault arise, please first check the following:

• Is the power plug plugged in?

• Is the unit switched on (see Chapter 8 (On/Off

switch))?

• Is the socket live?

• Is the display active?

• Lamp does not illuminate – switch on the lighting

with the light switch (see Chapter 8).

If the fault is not caused by any of these, please call

your customer service / service partner.

15. Exploded View Drawings and Parts Lists

Exploded view drawings and parts lists are available to

service partners.

GB

DECLARATION OF CONFORMITY

The manufacturer

AHT Cooling Systems GmbH

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA

Directives 2004/108/EC and 2006/95/EC.

The valid versions of the following standards were applied to the design and construction of the machines: EN 378:2008; EN ISO 23953:2005;

EN 60335-1:2002 + A11:2004 + A1:2004 + A12:2006 + A13:2008; EN 60335-2-89:2002 + A11:2004 + A1:2005; EN 50366:2003 + A1:2006; EN

55014-1:2000 + A1:2001 + A2:2002; EN 55014-2:1997 + A1:2001; EN 55015:2006; EN 61000-3-2:2006; EN 61000-3-3:1995 +A1:2001 +

Additionally for PROPAN R290 equipment: IEC / EN 60079-15:2005

Rottenmann, 06.02.2009

A2:2005; EN 61000-3-11:2000

Rottenmann, 17.12.2009

Techn. Geschäftsführer

Chief operating of

Direction technique

Entwicklungsleiter

R & D Manager

Responsable recherche

et développement

hereby declares that machines listed on page 1 of these operating and maintenance instructions correspond to the provisions of EEA Directives

2004/108/EG and 2006/42/EG.

16. Konformitätserklärung / Declaration of Conformity

• Change the absorption cloth in the condensate basin

• Plug the unit back in and allow it to run for 2 hours.

• Replace products

11. Taking the unit out of operation for

extended periods

• Move all products elsewhere.

• Unplug from the mains.

• Clean the unit

• If you are changing the location, adjust the height of

the levelling feet (see Chapter 5).

12. Changing the Lamp

13. Disposal

ATTENTION: Thermal insulation material

EPS

Do

not put the unit in with regular waste.

Please check your obligations in accordance

with the national WEEE provisions and the lo-

cal WEEE disposal partner. Ensure that the

piping is not damaged in the process.

polyurethane (PU) foam with carbon dioxide

(see Chapter 8).

EN 378-1:2008 + Ber.1:2010; EN 378-2:2008+A1:2009; EN 378-3:2008; EN 378-4:2008 + Ber1:2010; EN ISO 23953-1:2005;

EN ISO 23953-2:2005; EN 60335-1:2002 + A11:2004 + A1:2004 + A12:2006 + Cor.:2006 + A2:2006 + Cor.:2007-01 + Cor.:2007-

02 + A13:2008 + Cor.:2009 + Cor.:2010 + A14:2010; EN 60335-2-89:2010; EN 62233:2008 + Ber1:2008; EN 55014-1:2006 +

A1:2009; EN 55014-2:1997 + Corrigendum 1997 + A1:2001 + A2:2008; EN 55015:2006 + A1:2007 + A2:2009; EN 61000-3-

2:2006 + A1:2009 + A2:2009; EN 61000-3-3:2008; EN 61000-3-11:2000; EN ISO 14121-1:2007

Loading...

Loading...