BRAKE MICRO

SWITCH

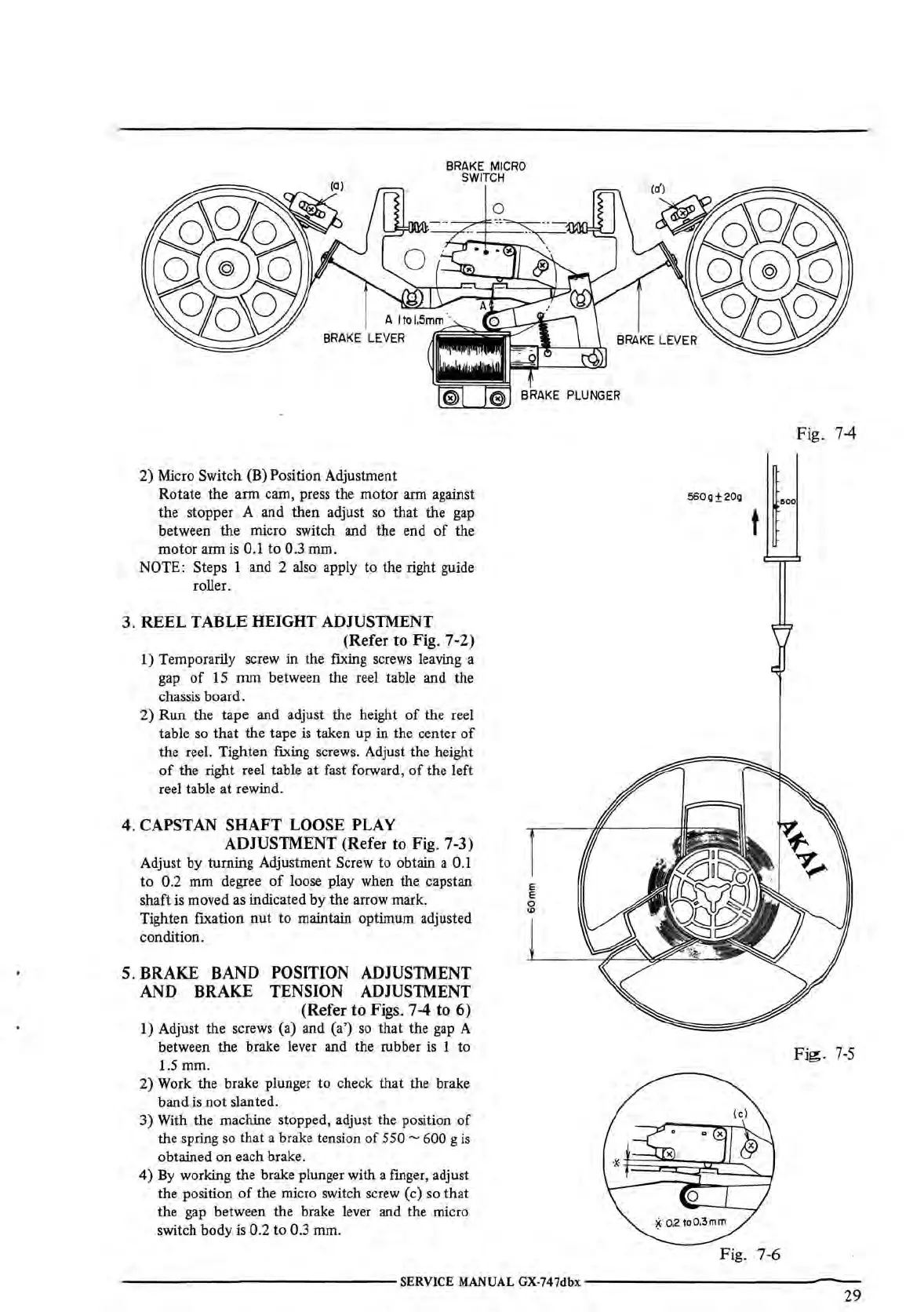

2) Micro Switch (B) Position Adjustment

Rotate the

arm

cam, press the motor arm against

the stopper A and then adjust

so

that the gap

between

the

micro switch and the end

of

the

motor

arm is 0.1

to

0.3 mm.

NOTE: Steps 1 and 2 also apply to the right guide

roller.

3.

REEL TABLE HEIGHT ADJUSTMENT

(Refer to Fig. 7-2)

1) Temporarily screw in the fixing screws leaving a

gap

of

15

mm

between the reel table and the

chassis board.

2)

Run

the tape and adjust the height

of

the reel

table

so

that

the tape

is

taken up in the center

of

the reel. Tighten fixing screws. Adjust the height

of

the right reel table at fast forward,

of

the left

reel table at rewind.

4. CAPSTAN SHAFT LOOSE PLAY

ADJUSTMENT

(Refer to Fig. 7-3)

Adjust by turning Adjustment Screw to obtain a 0.1

to

0.2 mm degree

of

loose play when the capstan

shaft

is

moved as indicated by the arrow mark.

Tighten fixation

nut

to maintain optimum adjusted

condition.

5. BRAKE BAND POSITION ADJUSTMENT

AND BRAKE TENSION ADJUSTMENT

(Refer to Figs. 7-4 to 6)

1)

Adjust the screws (a) and (a')

so

that the

gap

A

between the brake lever and the rubber is 1 to

1.5mm.

2) Work the brake plunger to check that the brake

band is

not

slanted.

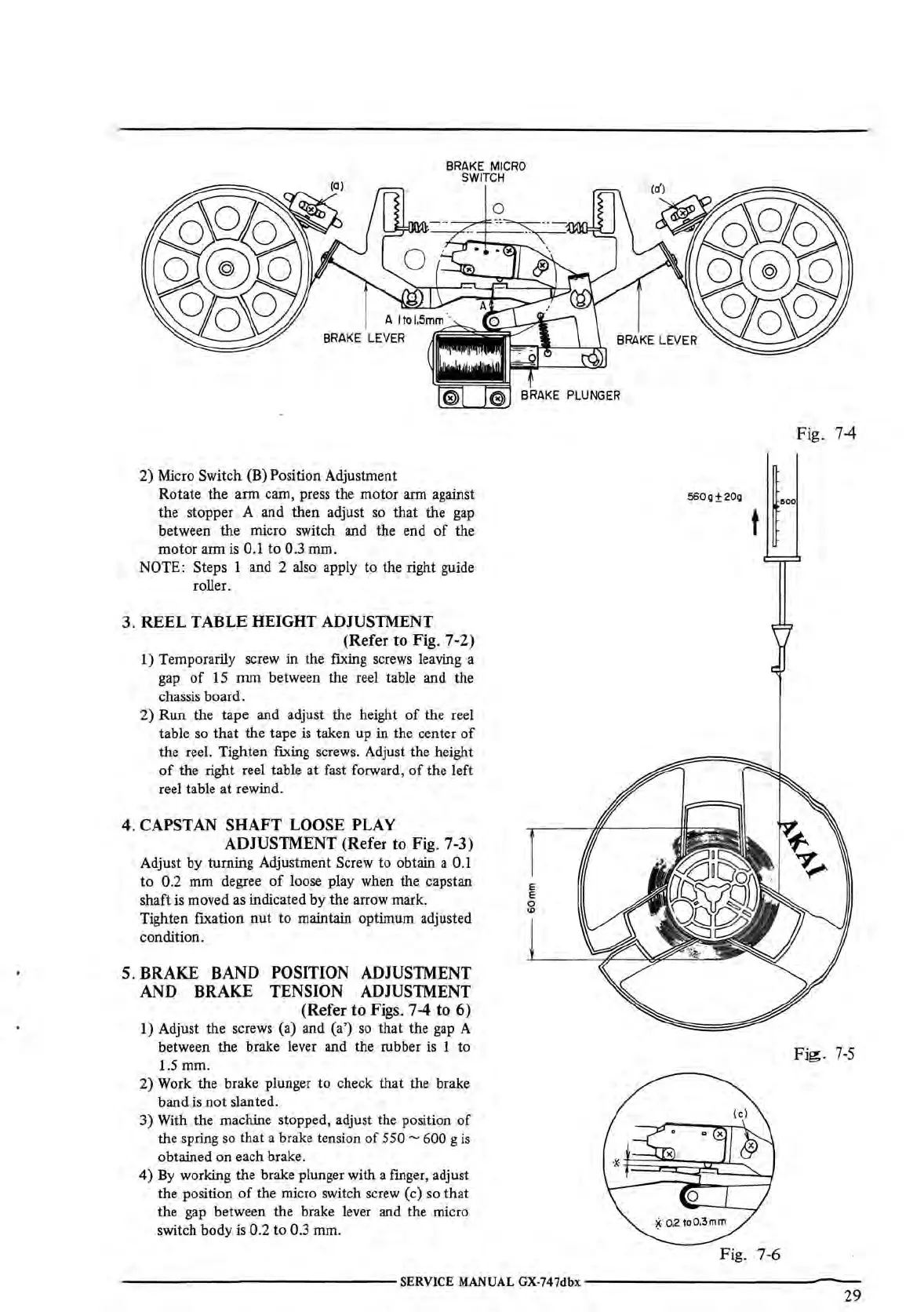

3) With the machine stopped, adjust the position

of

the spring so that a brake tension

of

550 ~ 600 g

is

obtained on each brake.

4)

By

working the brake plunger with a finger, adjust

the position

of

the micro switch screw (c)

so

that

the gap between the brake lever and the micro

switch body

is

0.2 to 0.3 mm.

E

E

0

<D

560g±20g

Fig. 7-4

Fig.

7-5

Fig. 7-6

---------------SERVICE

MANUAL

GX-747dbx

---------------

29

Loading...

Loading...