PINCH

ROLLER

PLUNGER

~o

CH

ROLLER

Fig. 7-8

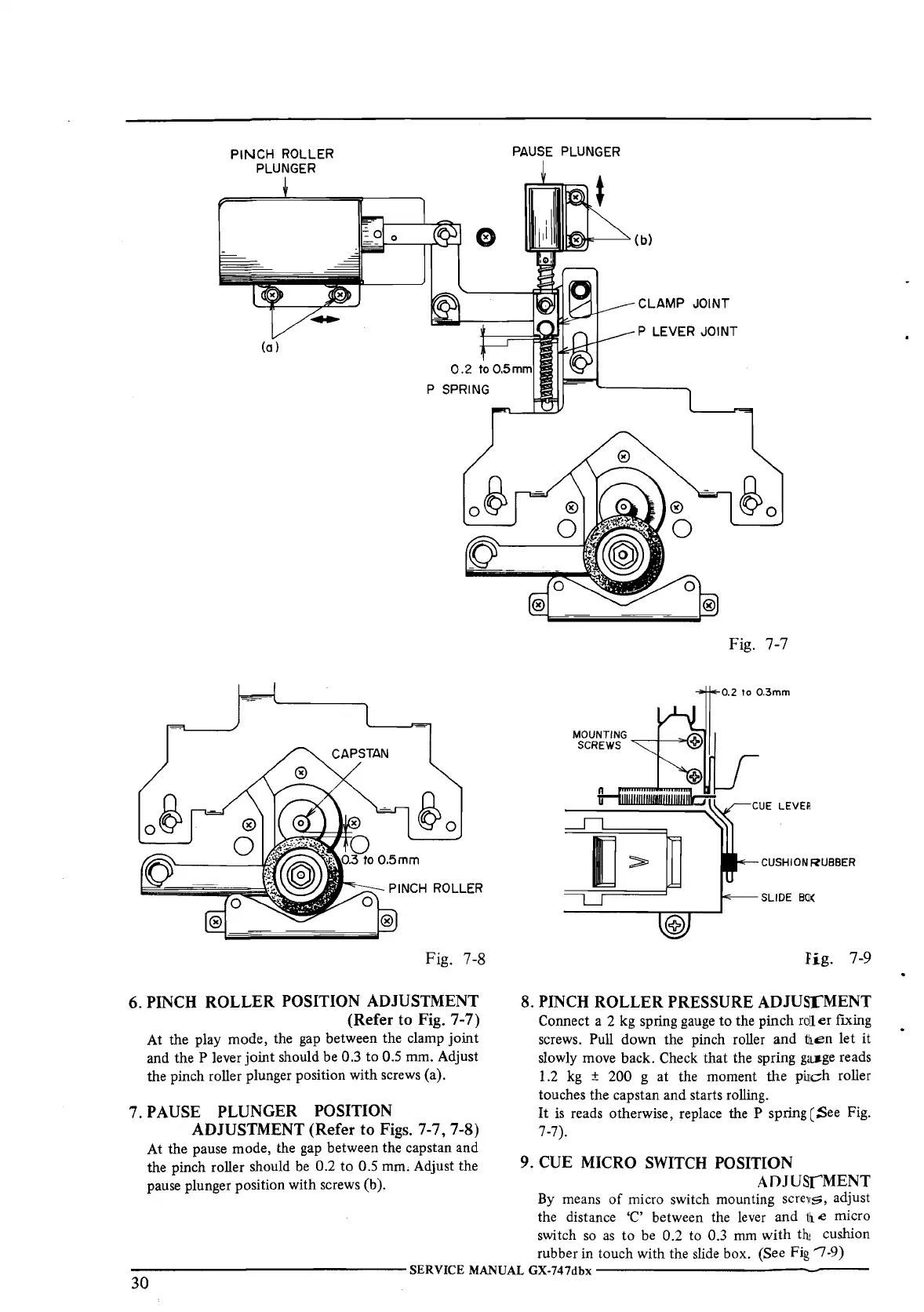

6. PINCH ROLLER POSITION ADJUSTMENT

(Refer

to

Fig. 7-7)

At the play mode, the gap between the clamp joint

and the P lever joint should be 0.3

to

0.5 mm. Adjust

the pinch roller plunger position with screws (a).

7. PAUSE PLUNGER POSITION

ADJUSTMENT (Refer to Figs.

7-7, 7-8)

At the pause mode, the gap between the capstan and

the pinch roller should

be

0.2

to

0.5 mm. Adjust the

pause plunger position with screws (b ).

PAUSE

PLUNGER

CLAMP JOINT

P LEVER JOINT

Fig. 7-7

0.2 to 0.3mm

CUSHION RUBBER

SLIDE

BO(

Fig.

7-9

8. PINCH ROLLER PRESSURE ADJUSrMENT

Connect a 2 kg spring gauge

to

the pinch

roll

er

fixing

screws. Pull down the pinch roller and

tli.en let it

slowly move back. Check that the spring

ga~ge

reads

1.2

kg

± 200 g at the moment

the

piJich roller

touches the capstan and starts rolling.

It

is

reads otherwise, replace the P spring ( See Fig.

7-7).

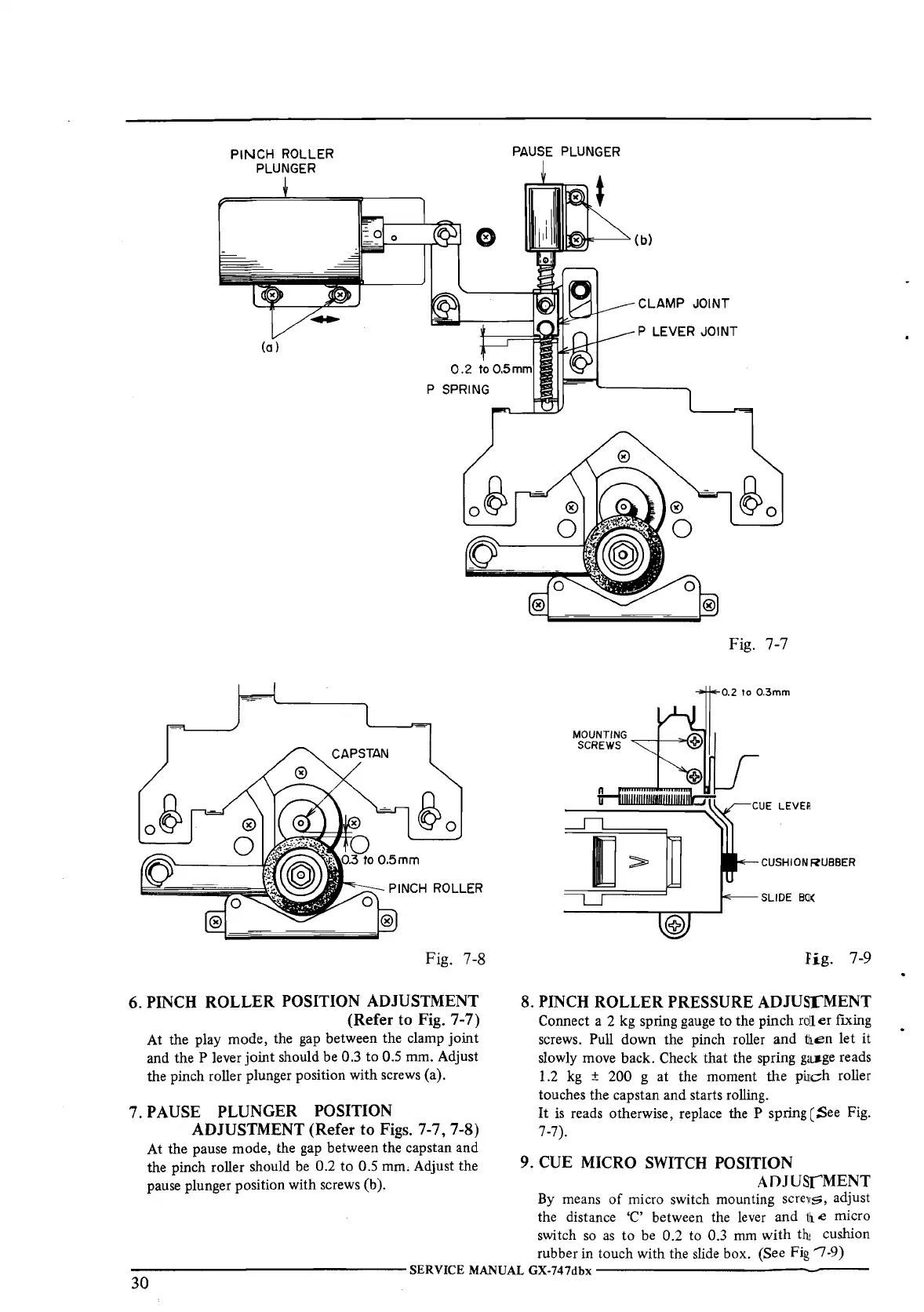

9. CUE MICRO

SWITCH

POSITION

ADJUSrMENT

By means

of

micro switch mounting scretsi, adjust

the distance 'C' between the lever and

1li

e micro

switch

so

as

to

be 0.2 to 0.3 mm

with

thi

cushion

rubber in touch with the slide box. (See

Fig '7-9)

---------------SERVICE

MANUAL

GX-747dbx

---------------

30

Loading...

Loading...