Publication 1746-UM022B-EN-P - January 2005

Programming Examples 5-7

calibration time to ensure that the new input data matches the channel

configuration requested. The above table shows how to calculate the

update time and auto-calibration time for the channel configuration

being used.

Interfacing to the PID

Instruction

The thermocouple module was designed to interface directly to the

SLC 5/02 or later processor PID instruction without the need for an

intermediate scale operation.

Example - Use 1746-NT8 channel data as the process variable in the

PID instruction.

1. Select scaled-for-PID as the data type in the channel

configuration word.

2. Specify the thermocouple channel data word as the process

variable for the PID instruction.

In this example, the value -32701 (8043 H) is the numeric equivalent

of configuration word N10:0 for channel 0. It is configured for a type

K thermocouple, scaled-for-PID, zero the signal for an open-circuit,

10 Hz, °C, and channel enabled.

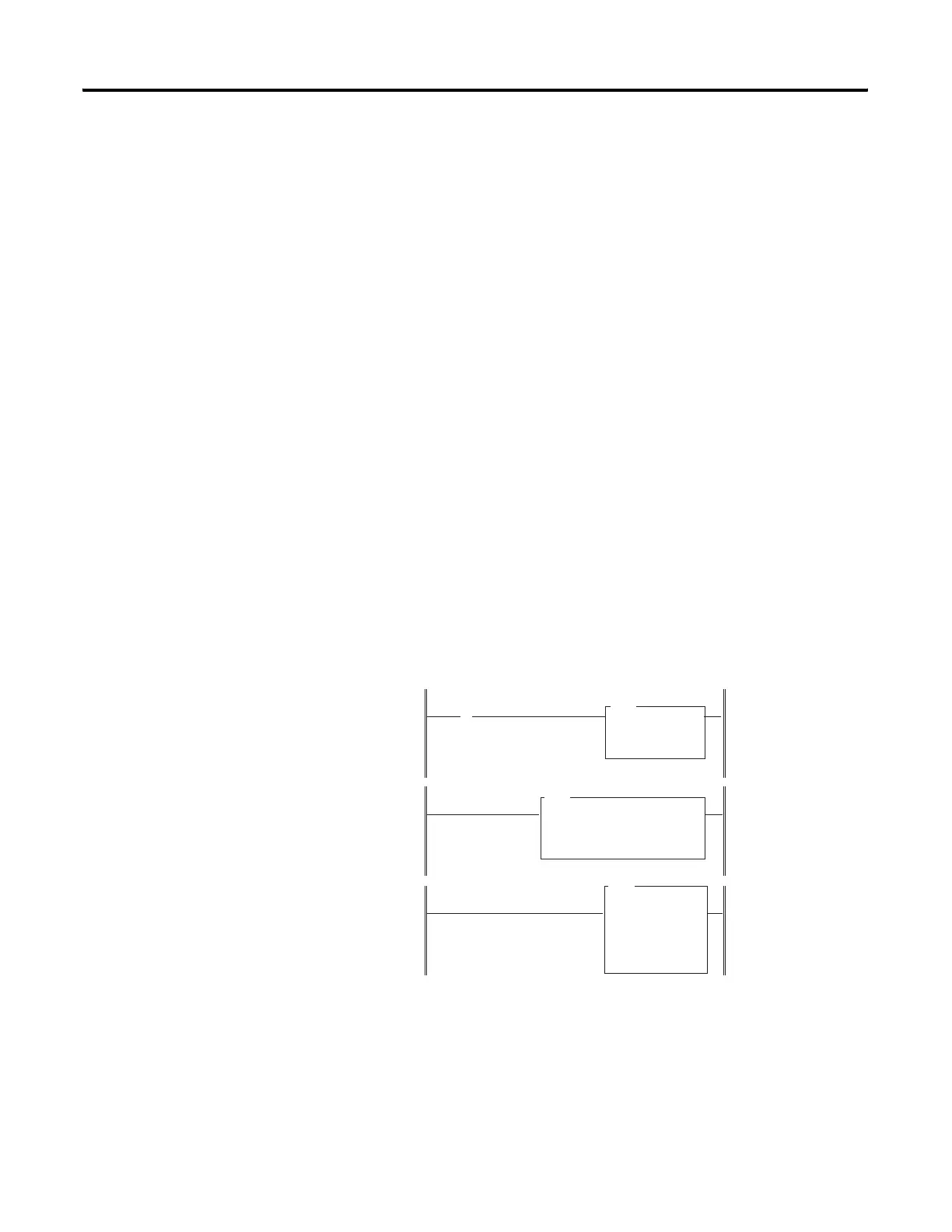

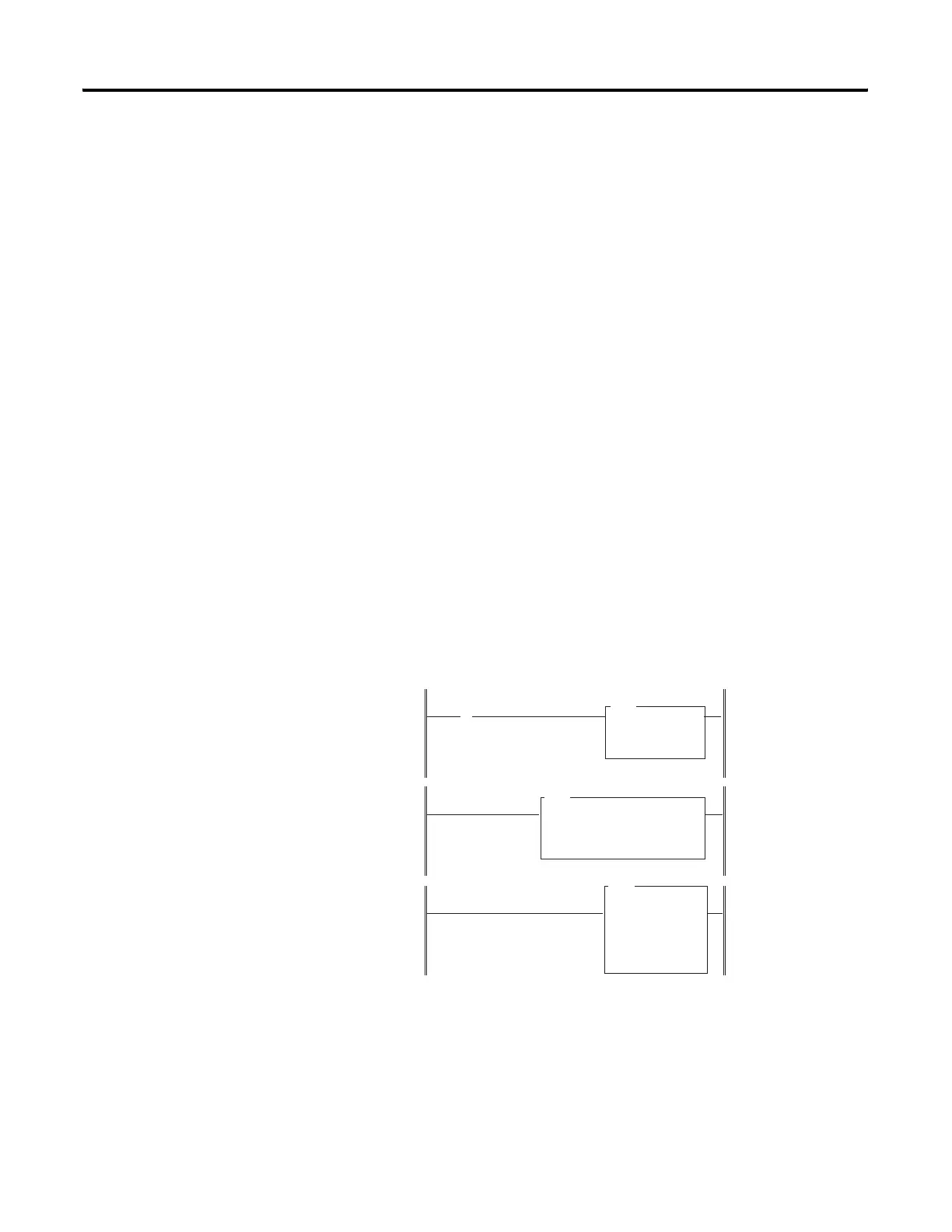

Programming for PID Control Example

MOV

MOVE

Source N10:0

-32701

Dest O:3.0

0

s:1

] [

15

PID

PID

Control Block N11:0

Process Variable I:3.0

Control Variable N11:23

Control Block Length 23

SCL

SCALE

Source N11:23

Rate [/10000]

Offset

Dest

First Pass Bit

Initialize NT8

Channel 0

Rung 2:0

Rung 2:1

Rung 2:2

The Rate and Offset parameters should be set per your application.

The Destination will typically be an analog output channel.

Loading...

Loading...