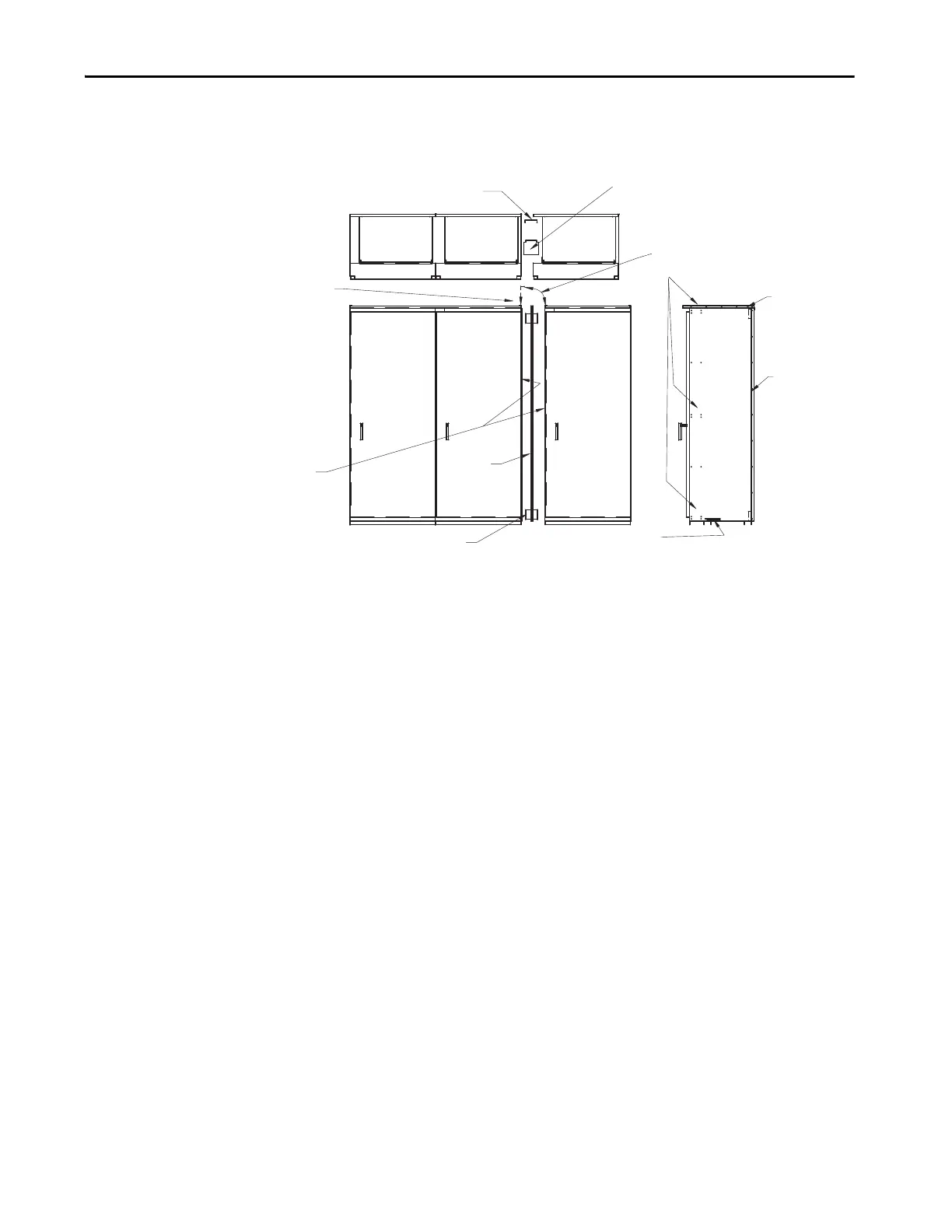

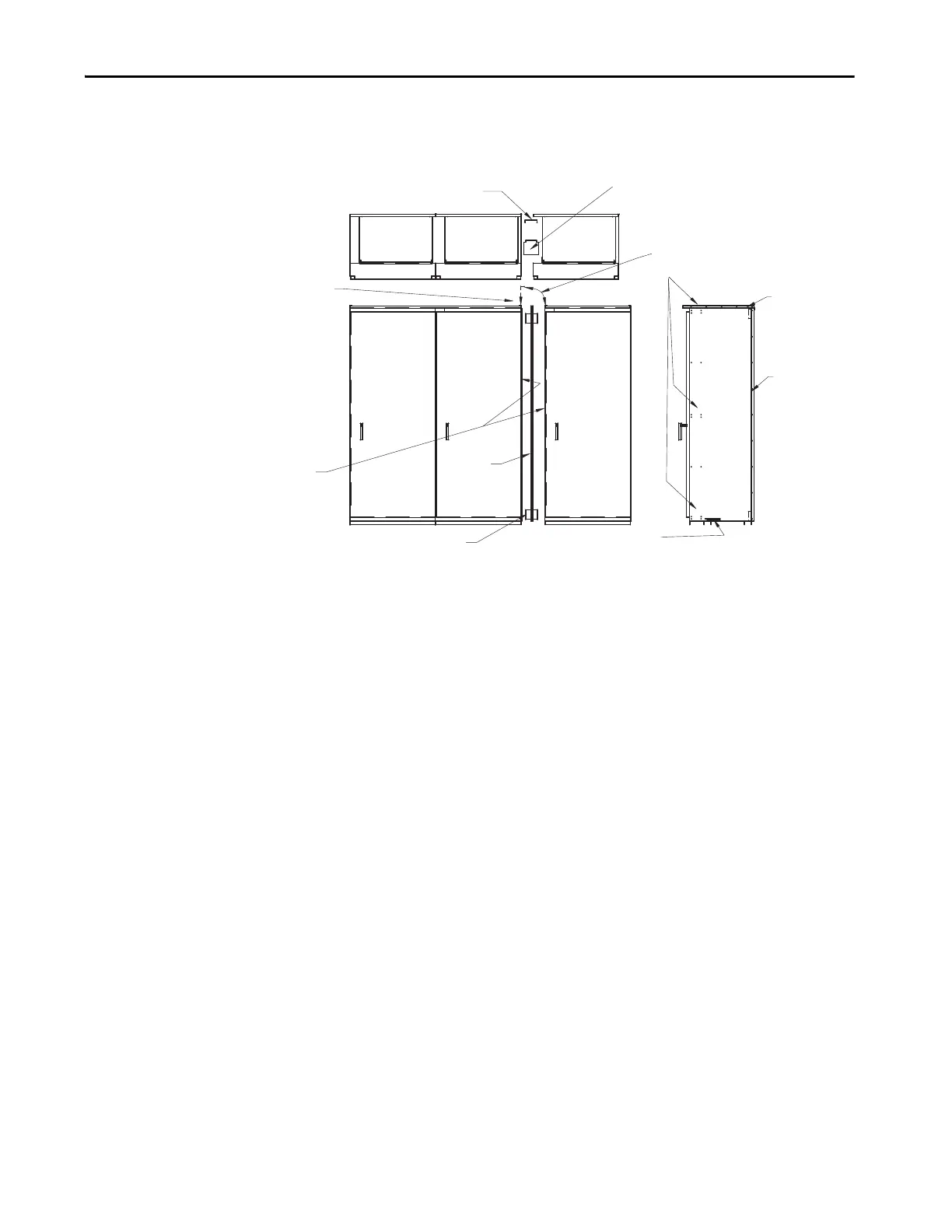

MCC MCC MCC

Cabinet Spacer

(2) 0.25 in. (6 mm) x 0.50 in. (12.7 mm) Taptites

Cabinet Spacer

(2) 0.25 in. (6 mm) x 0.50 in. (12.7

mm) Taptites

(2) 0.25 in. (6 mm) x 0.50 in. (12.7 mm) Taptites

Cabinet Spacer

(2) 0.25 in. (6 mm) x 0

in. (12.7 mm)

Tap tites

Gasket

Gasket

Wireway Extensions

(2) or (4) 0.25 in. (6 mm) x 0.50 in. (12.7

mm) Taptites

(2) wireway extensions required for 15 in. (381 mm) deep.

(2) wireway extensions required for 20 in. (508 mm) deep.

(1) 0.25 in. (6 mm) -20 x 0.70 in. (17.78 mm) taptite per wireway extension.

Remove left-hand driphood angle and remount after the

adjacent driphood has been drilled out.

Remove right-hand driphood angle and

discard. Drill out (5) 0.172 in. (4.36 mm)

diameter holes to 0.25 in. (6 mm) diameter in

driphood.

Remove the right-hand and left-hand side

plates before joining sections. The gasket is

across the top of the driphood and down

the backplate on one of the adjoining

sections.

Gasket

Loading...

Loading...