166 Rockwell Automation Publication 2198-UM002G-EN-P - February 2019

Chapter 5 Connect the Kinetix 5700 Drive System

Include a new 12 mm (0.5 in.) section of cable jacket and slide it down

to the end of the shield braid.

3. Apply heat shrink to the small section of cable jacket.

Refer to Figure 111

for typical installation examples for series A and series B

cables. For strip lengths and torque values, refer to Tab l e 7 5

and Tabl e 76 on

page 153

.

Dual-axis Inverter Shield Clamp Installation

Follow these steps to apply the dual-axis inverter cable shield clamp.

1. Loosen the clamp knob and determine if you need the clamp spacers.

The power/brake cable shield attaches to the dual-axis inverter cable

clamp. Clamp spacers are included with the dual-axis inverters for cable

diameters that are too small for a tight fit within the drive clamp alone.

The spacers are held captive by nylon rivets. Remove the rivets and

spacers when your cable shield is of sufficient diameter for the clamp to

hold the cable secure.

2. Position the exposed portion of each cable braid directly in line with the

clamp.

3. Hand tighten the clamp knob.

Make sure the cable clamp tightens around the cable shield and provides

a good bond between the cable shield and the drive chassis.

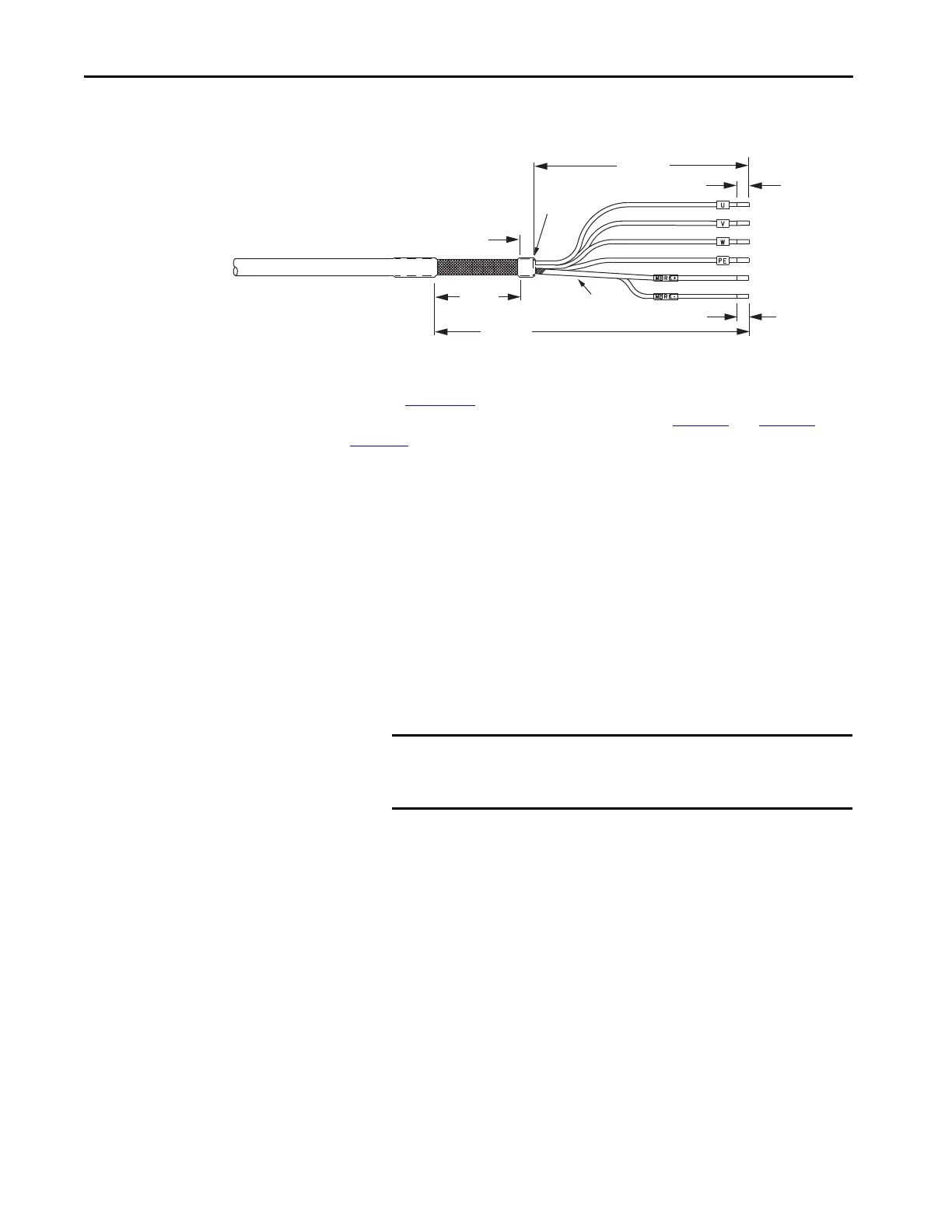

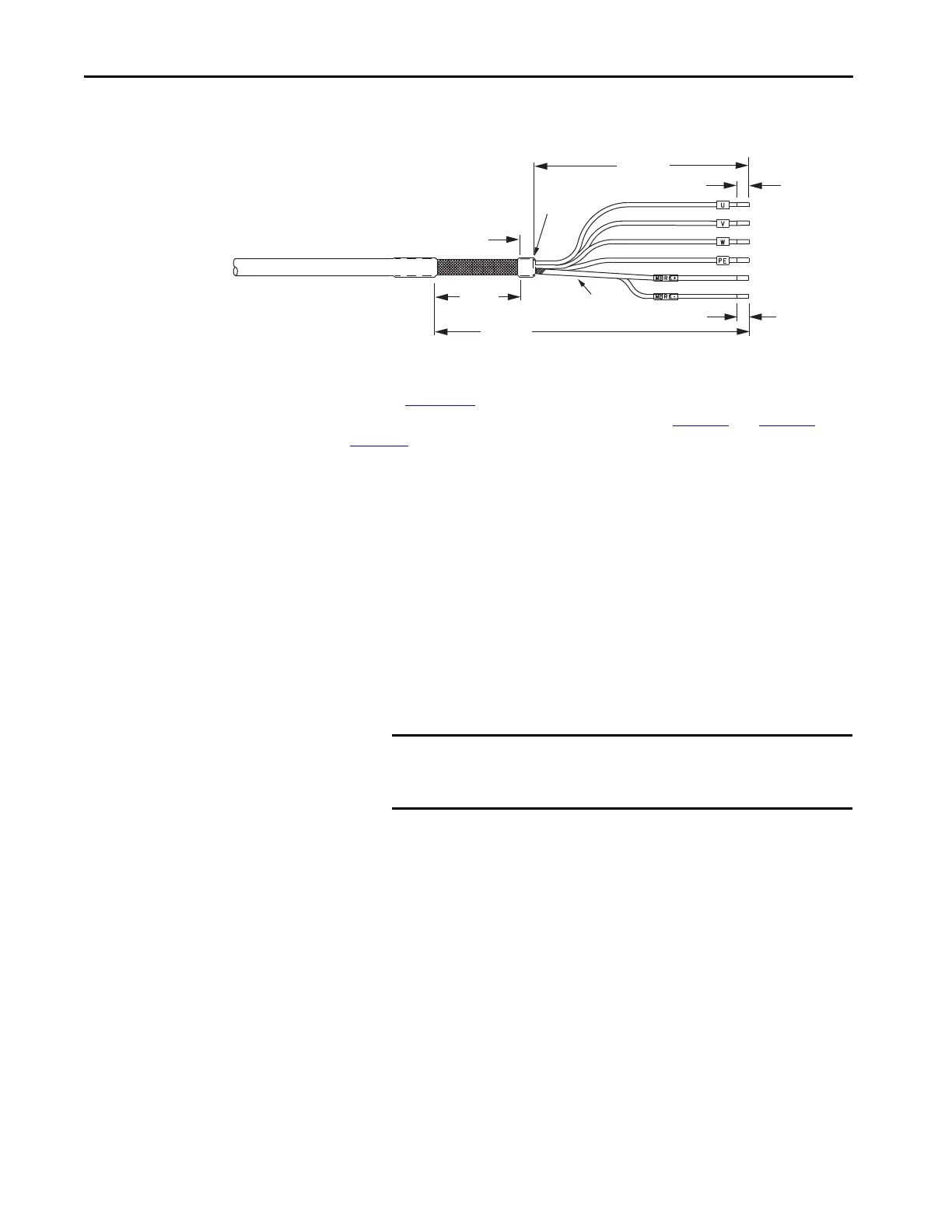

7.0 (0.28)

305 (12)

221 (8.7)

10.0 (0.39)

12 (0.50)

71 (2.8)

Dimensions are in mm (in.)

Power Conductors

Brake

Conductors

MP-Series Motors

and Actuators

Brake Shield

(trimmed back)

Edge of

Cable Jacket

IMPORTANT Most 2090-CPxM7DF power/brake cables require the spacers.

Only 10 AWG cables with brake conductors have a diameter

large enough to fit in the clamp without the spacers.

Loading...

Loading...