Rockwell Automation Publication 2198-UM002G-EN-P - February 2019 27

Start Chapter 1

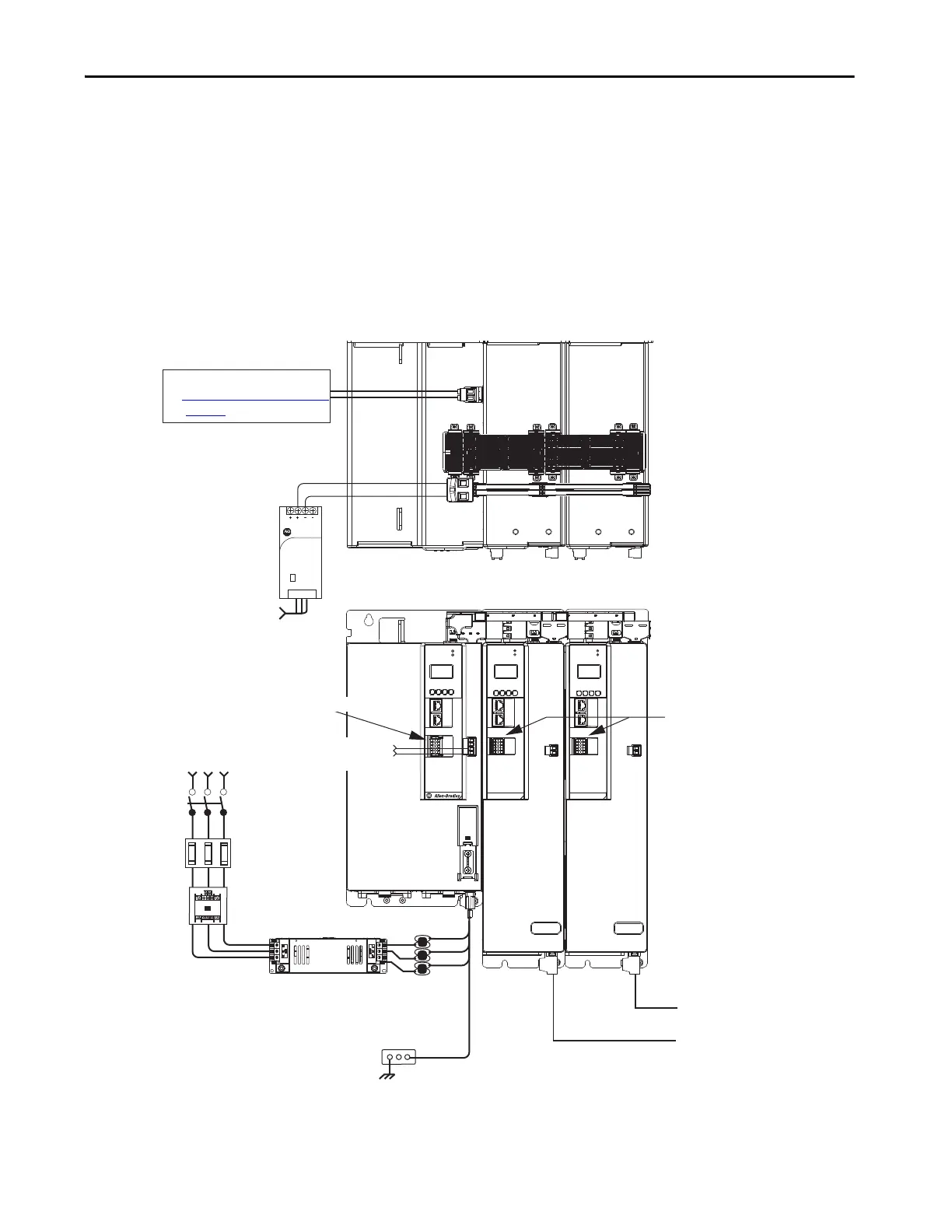

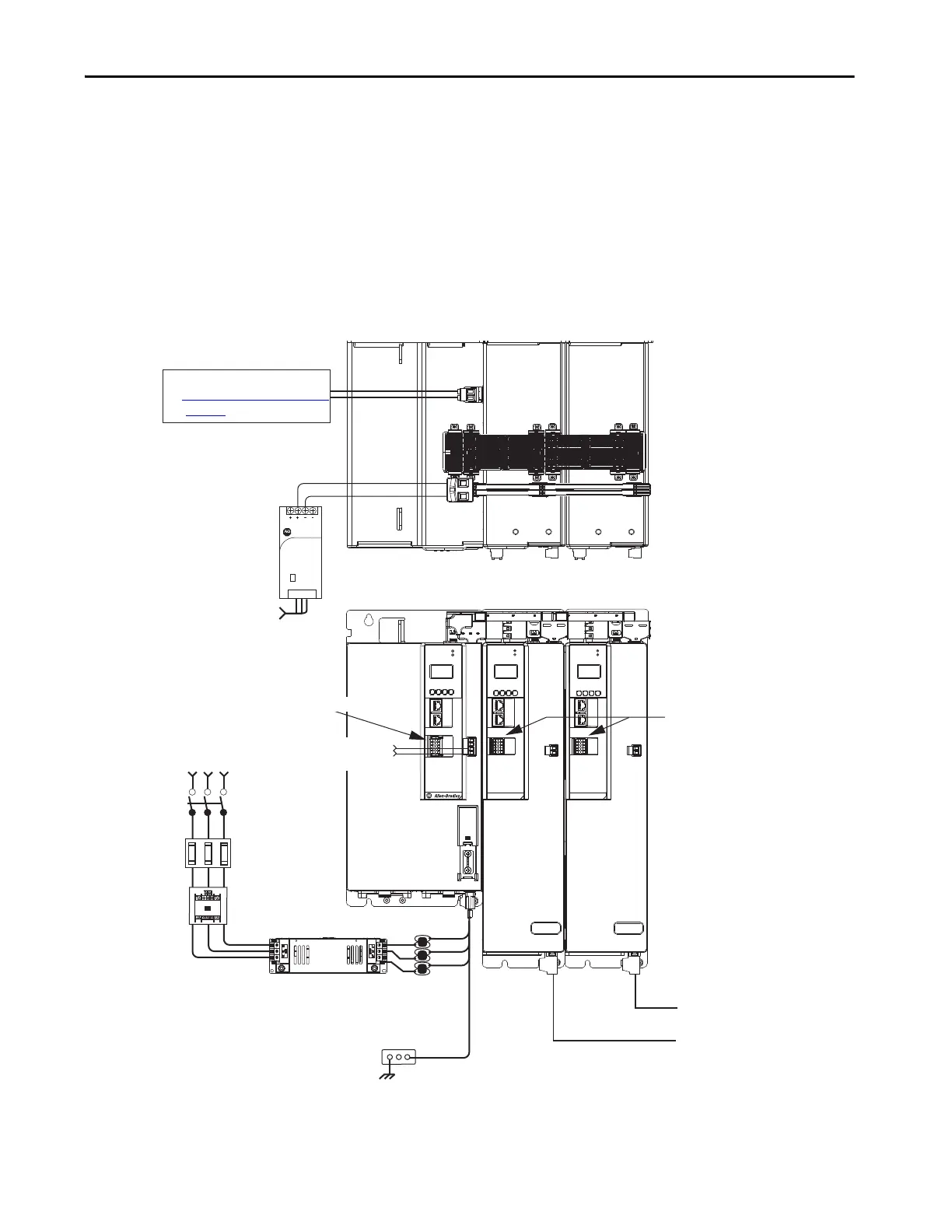

iTRAK Power Supply Configuration Example

In this example, AC input power is fed to the regenerative bus supply. Two

iTRAK power supplies support up to 40 iTRAK motor modules, depending

on cable lengths and iTRAK motor-module power consumption.

Digital inputs are wired to sensors and the control circuitry at the IOD

connectors. The contactor-enable relay protects the regenerative bus supply in

the event of shutdown fault conditions.

Figure 9 - Typical iTRAK Power Supply Installation

2

1

16

I/O

510

–

iPS RDY

+

MOD–

NET–

1

2

3

4

5

6

7

8

9

10

2

1

16

I/O

510

–

iPS RDY

+

MOD–

NET–

1

2

3

4

5

6

7

8

9

10

1606-XL

Power Supply

Input

Allen-Bradley

DC+

MOD

NET

2

1

1

I/O

6

5

10

OK+

OK–

EN–

EN+

DC–

Magnetic Contactor

(M1) Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and iTRAK Motor Module Control Power

(customer-supplied)

AC Input Power

Kinetix 5700 iTRAK System

(front view)

Kinetix 5700 iTRAK System

(top view)

Line Disconnect

Device

324…506V AC

Three-phase

Input Power

Circuit

Protection

Magnetic (M1)

Contactor

Bonded Cabinet

Ground Bus

Converter Digital Inputs

iTRAK Motor Modules

Regenerative Bus Supply

iTRAK

Power Supply

iTRAK

Power Supply

iTRAK Motor Modules

iTRAK Power Supply

Digital Inputs

Bulletin 2198 shared-bus

connection system for DC-bus and

24V DC control power.

Shared DC-bus Power Input

Shared 24V Control Power Input

(24V shared-bus connection system

is optional)

2198T-CHBFLS8

Motor Power

Cables

Active Shunt (optional component)

See External Active-shunt Connections

on page 183

for more information.

Bulletin 1321

Line Reactor

(recommended)

2198-DBRxx-F

AC Line Filter

(can be required for CE)

Loading...

Loading...