2-14 Analog Inputs

Signal Loss

[Analog In 1, 2 Loss]

Signal loss detection can be enabled for each analog input. The [Analog In

x Loss] parameters control whether signal loss detection is enabled for each

input and defines what action the drive will take when loss of any analog

input signal occurs.

One of the selections for reaction to signal loss is a drive fault, which will

stop the drive. All other choices make it possible for the input signal to

return to a usable level while the drive is still running.

• Hold input

• Set input Lo

• Set input Hi

• Goto Preset 1

• Hold Output Frequency

If the input is in current mode, 4 mA is the normal minimum usable input

value. Any value below 3.2 mA will be interpreted by the drive as a signal

loss, and a value of 3.8 mA will be required on the input in order for the

signal loss condition to end.

If the input is in unipolar voltage mode, 2V is the normal minimum usable

input value. Any value below 1.6 volts will be interpreted by the drive as a

signal loss, and a value of 1.9 volts will be required on the input in order for

the signal loss condition to end.

No signal loss detection is possible while an input is in bipolar voltage

mode. The signal loss condition will never occur even if signal loss

detection is enabled.

Trim

An analog input can be used to trim the active speed reference (Speed

Reference A/B). If analog is chosen as a trim input, two scale parameters

are provide to scale the trim reference. The trim is a +/- value which is

summed with the current speed reference. See also

Speed Reference on

page 2-144.

• [Trim In Select]

• [Trim Out Select]

• [Trim Hi]

• [Trim Lo]

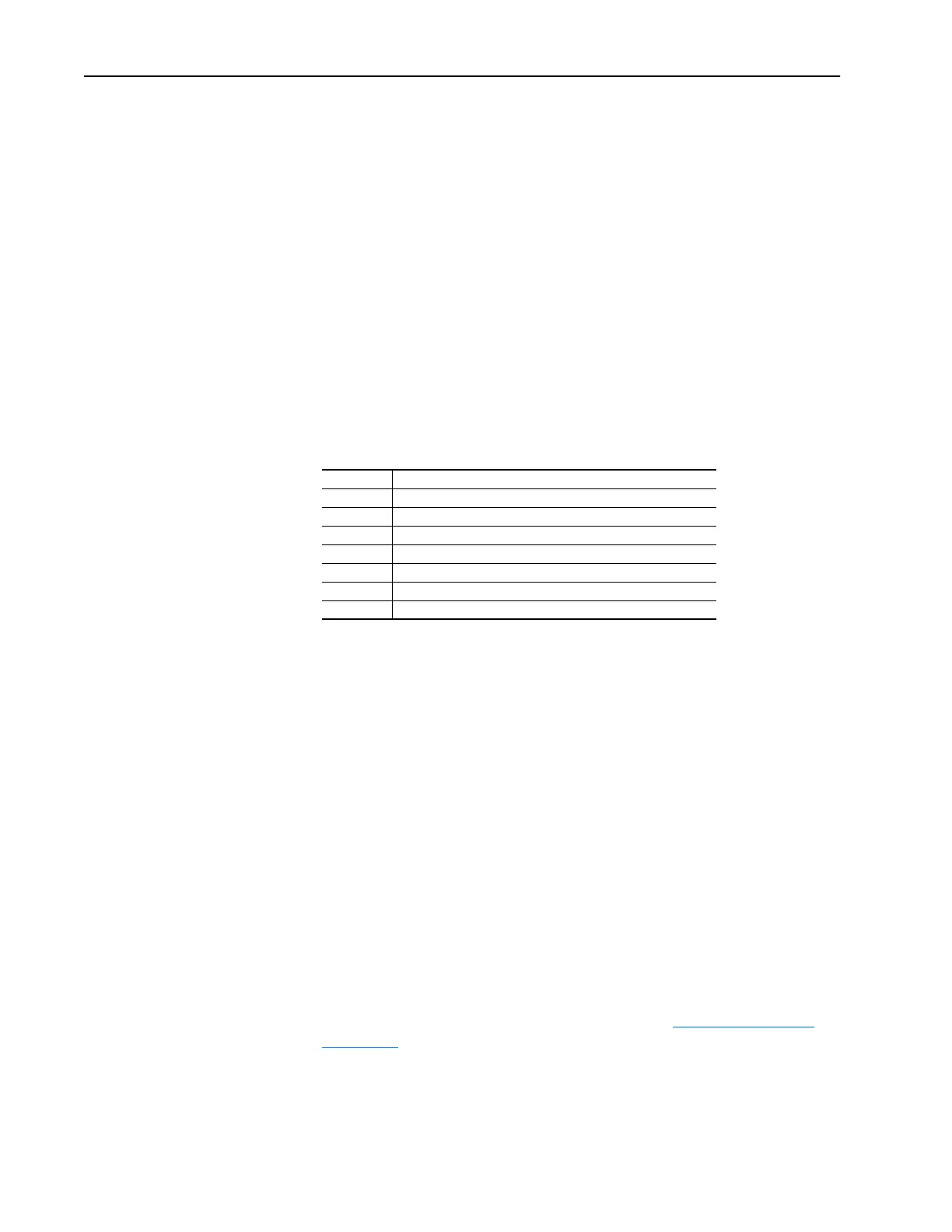

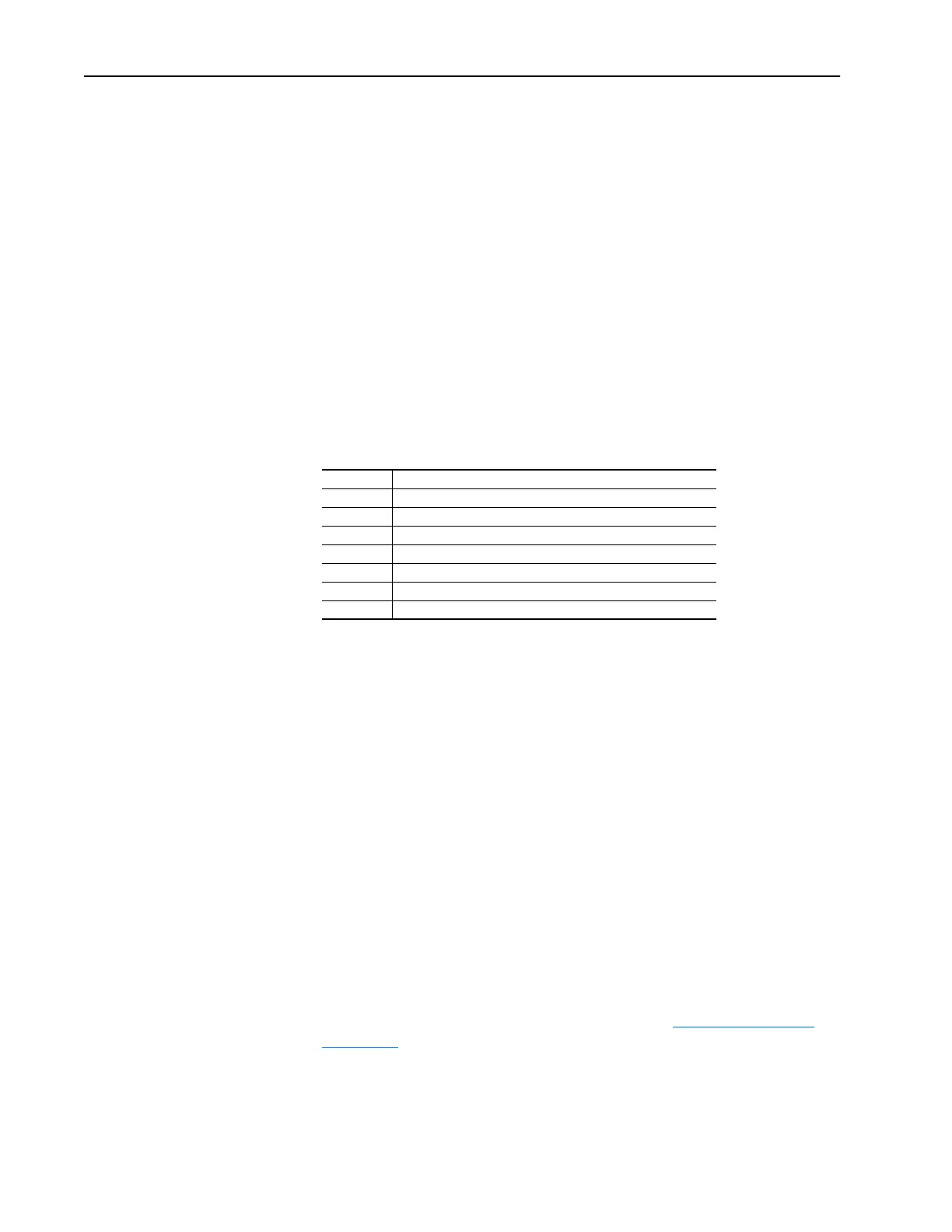

Value Action on Signal Loss

0 Disabled

1 Fault

2 Hold input (continue to use last frequency command.)

3 Set Input Hi - use [Minimum Speed] as frequency command.

4 Set Input Lo - use [Maximum Speed] as frequency command.

5 use [Preset 1] as frequency command.

6 Hold Out Freq (maintain last output frequency)

Loading...

Loading...