Multi-Axis Coordinated Motion Instructions

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 469

Coordinated Transform This stop type cancels the transforms associated with the specified coordinate system. All transform-related motion stops on

all associated target coordinate systems. However, source coordinate axes will continue to move as instructed.

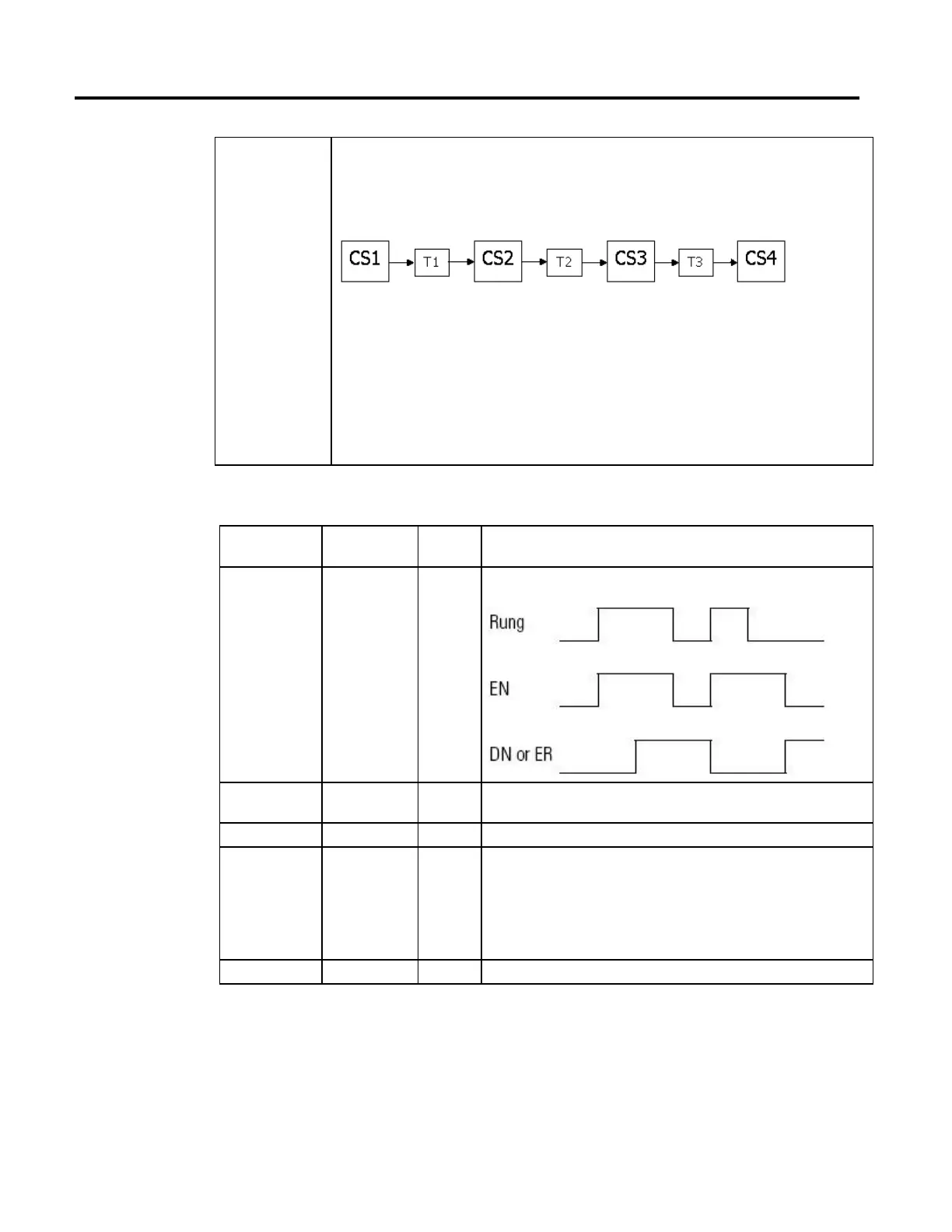

Example

If four coordinate systems are linked via three transforms. And the first coordinate system (CS1) is the source and is

processing commanded motion.

Executing an MCS instruction on CS2 and using a stop type of coordinated transform results in:

• Transforms T1 and T2 are canceled.

• Transform T3 stays active.

• the axes in CS1 stay in motion.

• the axes in Coordinate Systems CS2 and CS3 stop via the deceleration rate selected in the MCS instruction or the

maximum coordinate deceleration rate.

• the axes in CS4 follow the respective CS3 axes.

In an Motion Axis Stop (MAS) instruction, a stop type of all also cancels transforms.

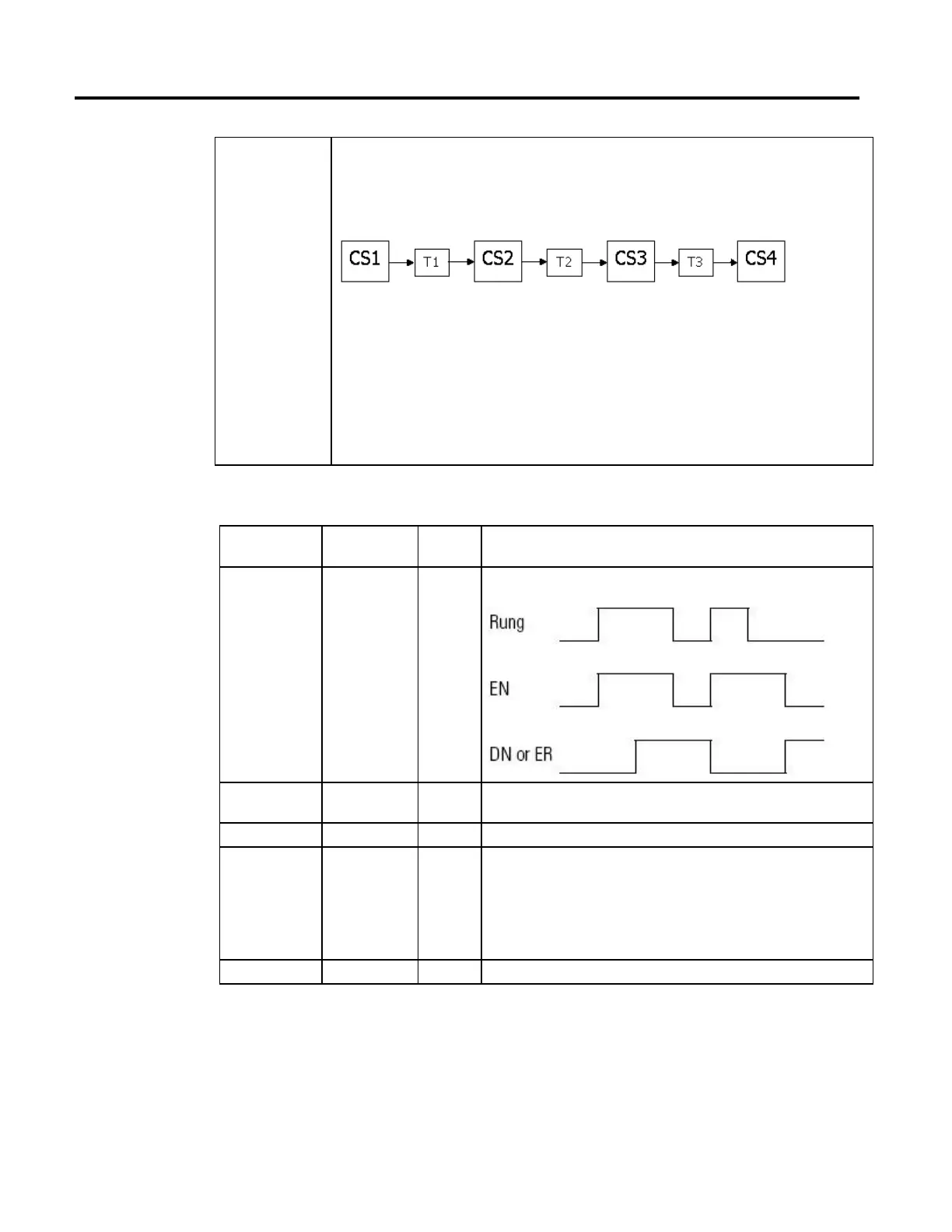

MOTION_INSTRUCTION Data Type

To see if Check if this bit is

on

Data Type Notes

The rung is true EN BOOL Sometimes the EN bit stays on even if the rung goes false. This happens if the rung goes

false before the instruction is done or an error has occurred.

The stop was

successfully initiated

DN BOOL

An error happened ER BOOL

The axis is stopping IP BOOL Any of these actions ends the MCS instruction and turns off the IP bit:

• The coordinate system is stopped.

• Another MCS instruction supersedes this MCS instruction.

• Shutdown instruction.

• Fault Action.

The axis is stopped PC BOOL The PC bit stays on until the rung makes a false-to-true transition.

Master Driven Speed Control (MDSC) and the MCS Instruction

If an MCS is issued when in Master Driven Mode, a switch is made to Time

Driven Mode and the axes are stopped in Time Driven Mode. MCS All resets the

IP bit of the Master Driven Coordinate Control (MDCC) instruction. Other

stop types do not reset the IP bit.

Loading...

Loading...