Common attributes for Motion instructions

666 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

• x = 0;

• }

• z = y + x;

Or another example:

• x = x + some_tiny_number;

• if (x >= 100)

• {

• z = z + 100;

• x = x - 100; // there might be a tiny remainder

• }

When using LINT data types, many limitations apply. A LINT data type cannot

be used in most instructions. LINT data type is:

• A 64-bit word.

• Not supported by products that use 32-bit words.

• Not supported in most instructions.

Tip:

LINTs can only be used with copy (COP, CPS) instructions. They are used with the

CST/WallClock Time attribute, time synchronization and Add-On Instructions. You

cannot add, subtract, multiply, or divide this tag type.

When using LINT data types, consider the following descriptions when these

issues occur.

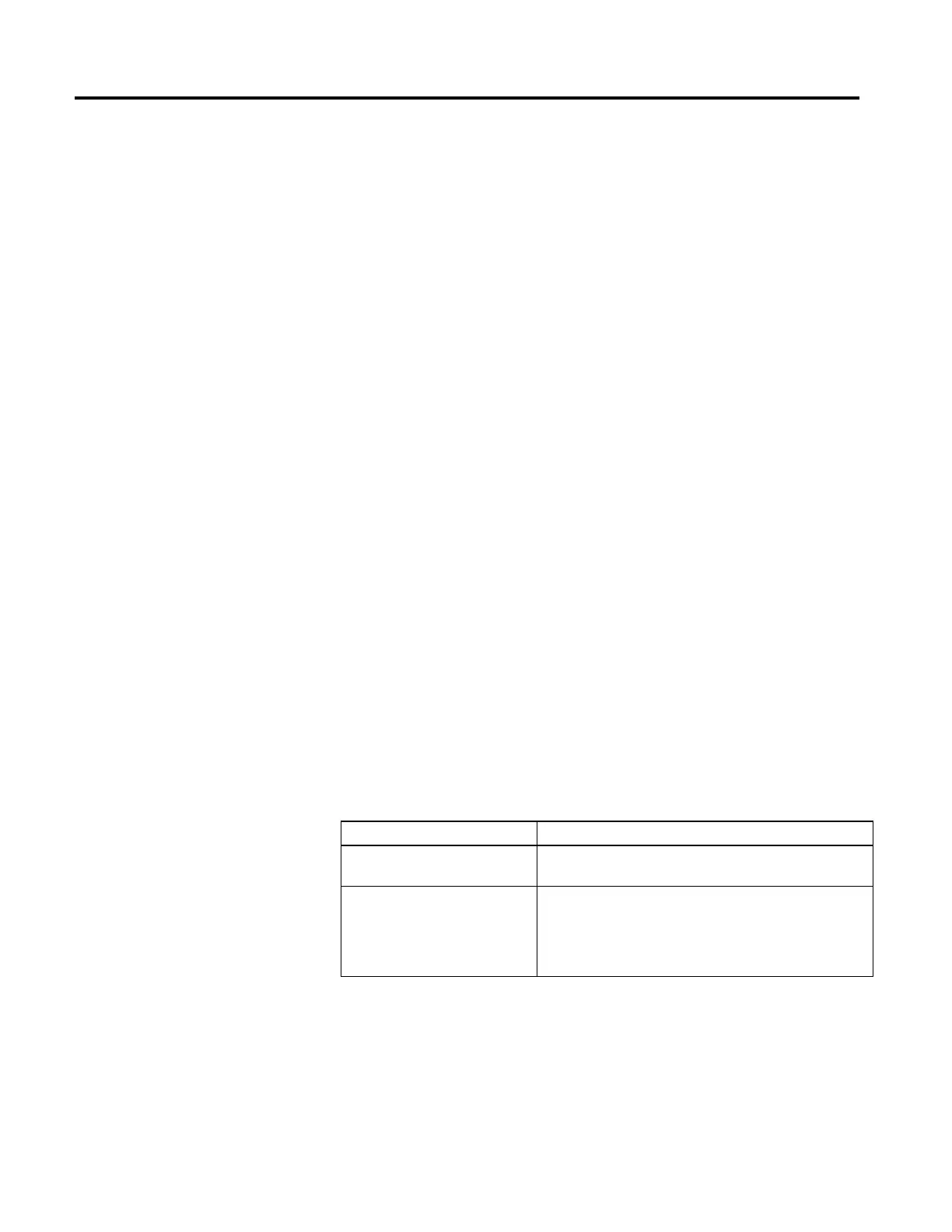

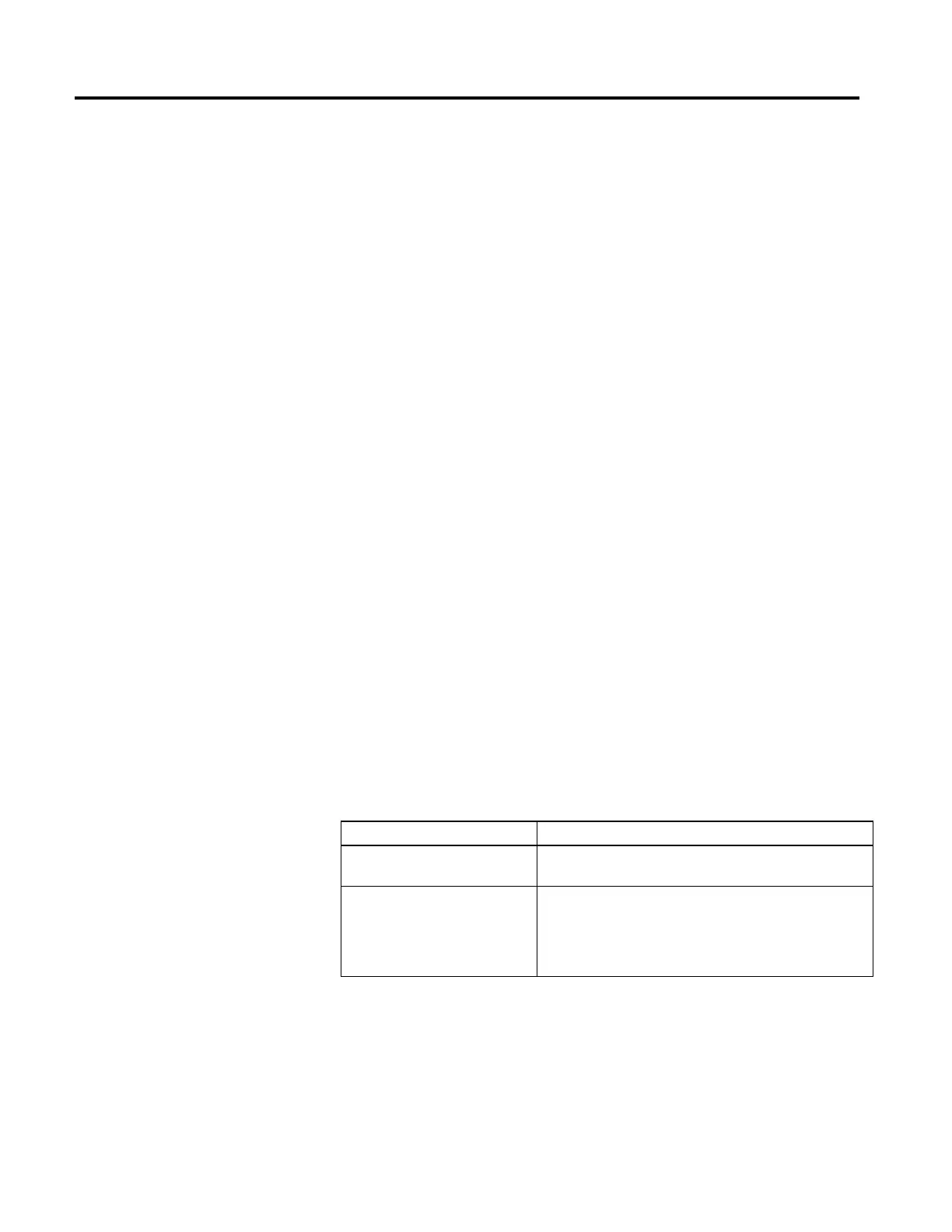

How to Description

Move/copy two double-integer DINT values

into one LINT

Create a double integer array of two elements, total of 64 bits (that is,

DINT[2], which can then be copied into one long integer.

Correct Date/Time Display error When a tag has a negative value, it cannot be displayed as Date/Time. In

the tag editor, check whether the value is negative by changing the style of

the tag from Date/Time to Binary. When the most significant bit (leftmost

one) is 1, the value is negative and therefore cannot be displayed as a Date

or Time.

Loading...

Loading...