Motion State Instructions

78 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

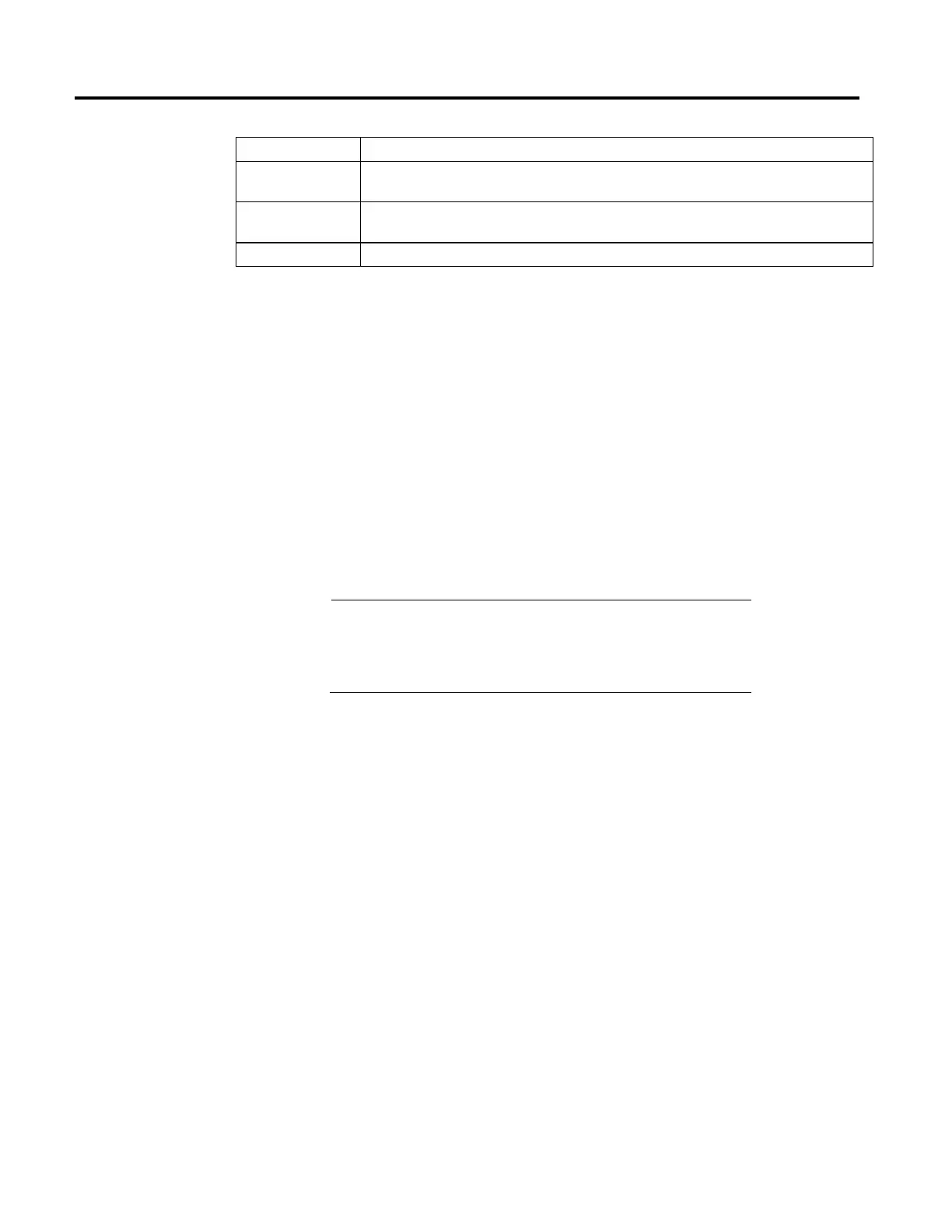

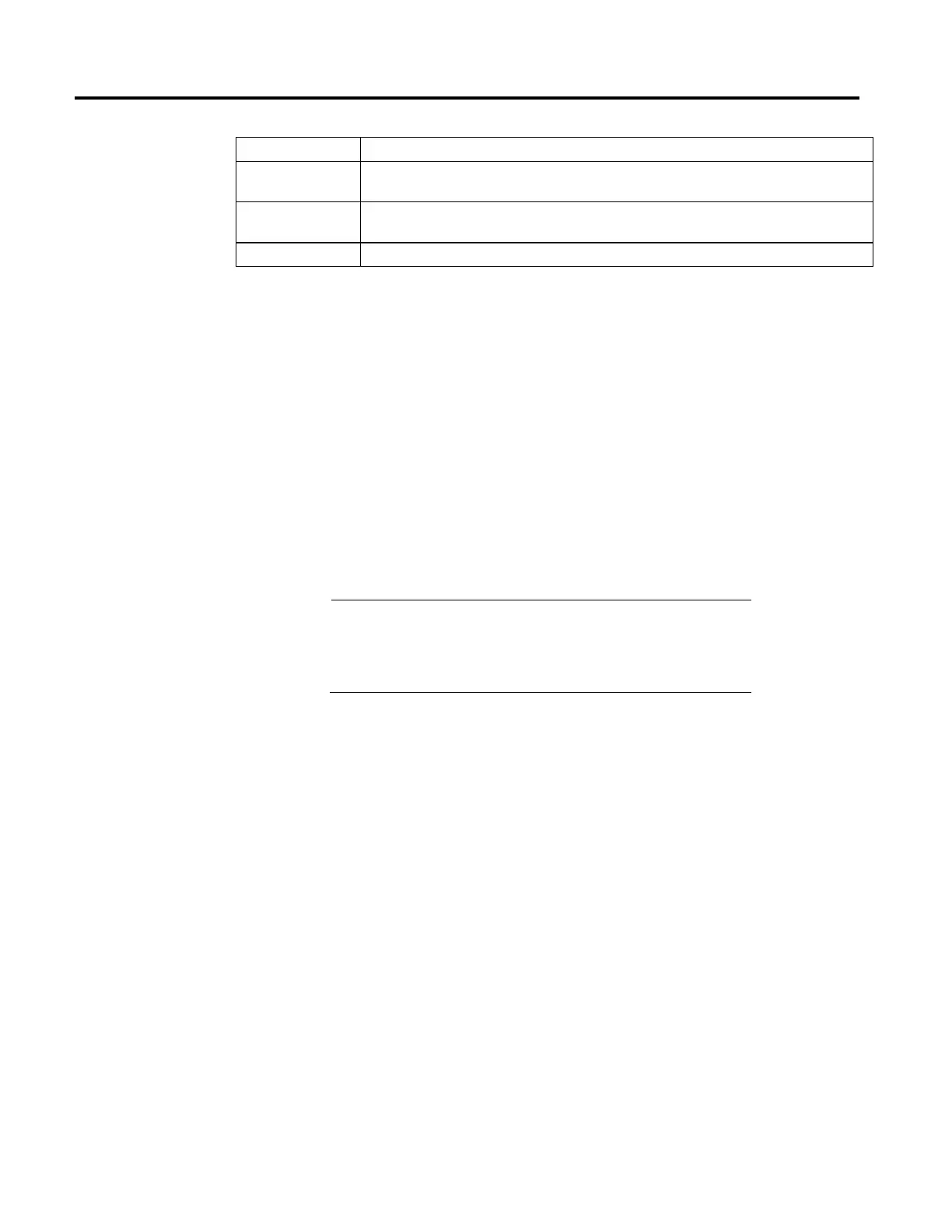

Mnemonic Description

.EN (Enable) Bit 31 It is set when the rung makes a false-to-true transition and remains set until the servo message transaction is

completed and the rung goes false.

.DN (Done) Bit 29 It is set when the axis’ servo action has been successfully enabled and the drive enable and servo active status bits

have been set.

.ER (Error) Bit 28 It is set to indicate that the instruction detected an error, such as if you specified an unconfigured axis.

Description

The MSO instruction directly activates the drive and enables the configured servo

loops associated with a physical servo axis. It can be used anywhere in a program,

but should not be used while the axis is moving. If this is attempted, the MSO

instruction generates an Axis in Motion error.

The MSO instruction automatically enables the specified axis by activating the

drive and by activating the associated servo loop. With a non-CIP axis, the

resulting state of the axis is referred to as the Servo Control state. With a CIP axis,

the resulting state of the axis is referred to as the Running state.

The most common use of this instruction is to activate the servo loop for the

specified axis in its current position in preparation for commanding motion.

Important:

The instruction execution may take multiple scans to execute because it

requires multiple coarse updates to complete the request. The Done (.DN)

bit is not set immediately, but only after the request is completed.

In this transitional instruction, the relay ladder, toggle the Rung-condition-in

from cleared to set each time the instruction should execute.

Affects Math Status Flags

No

Major/Minor Faults

None specific to this instruction. See Common Attributes for operand-related

faults.

Loading...

Loading...