© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

1300003 (EN)

18

Gas Technical Specifications for CE

Models

Inlet Pressure

Use a manometer to verify that the inlet pressure meets

the following requirements:

Natural Gas service must be supplied at

7.0 ± 1.5 inch water column pressure

(1.74 ± 0.37 kPa).

L.P. (Liquefied Petroleum) Gas service must be

supplied at 11 ± 0.3 inch water column pressure

(2.74 ± 0.07 kPa).

Manifold Pressure

To check manifold pressure, use a manometer to verify

that the settings of the gas valve correspond with the

type of gas being used.

1. Connect the manometer to the pressure

connection located on top of the gas valve while

the burner is ignited.

2. Read the manometer to determine the pressure of

the gas. The measured gas pressure must be equal

to the pressure indicated on the finisher’s serial

plate.

3. Install a pressure regulator valve (obtain locally),

suited for the nature and flow rate of the gas

used, in the tube system near the finisher.

Country

Gas

Category

Gas

Designation

Pressure

(mbar)

DE

I2ELL G20 20

G25 20

I3P G31 50

AT/DK/FI/IT/

SE

I2H G20 20

IE/PT/GB/GR

II2H3P G20 20

G31 37

CH/ES

II2H3P G20 20

G31 37 and 50

BE

I2E+ G20 20

G25 25

I3P G31 37

FR

II2Esi3P G20 20

G25 25

G31 37 and 50

LU

II2E3P G20 20

G31 50

NL

II2L3P G25 25

G31 50

Table 4

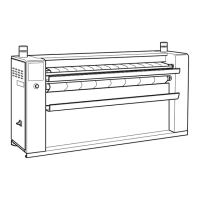

D233i

1 New Stainless Steel Flexible Connector –

Use only if allowed by local codes (Use

Design A.G.A. Certified Connector)

2 1/8 in. NPT Pipe Plug

(For checking inlet gas pressure)

3 Equipment Shut-Off Valve – Installed within

6 ft. (1.8 m) of finisher

4 Black Iron Pipe

5 1 inch Gas Connection

Figure 8

Loading...

Loading...