© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

1300003 (EN)

Maintenance

NOTE: SHUTDOWNS due to unscheduled

maintenance can be AVOIDED or MINIMIZED

by:

• Performing periodic inspections as described,

and

• Performing lubrication services at the time

intervals specified in these instructions.

Following are recommended precautions that

personnel must understand and apply when

performing general periodic maintenance tasks.

IMPORTANT: ALL maintenance must ALWAYS

be carried out when the finisher is stopped, the

cylinder is cold, and the circuit break is in

position 0 (OFF).

Check Operation of Air Vacuum

Switches

Place a metal plate with a hole size of Ø60 millimeters

(2.36 in.) on top of exhaust pipe. Switch should not

trip. Next, place a metal plate with hole size of Ø55

millimeters (2.17 in.) on top of exhaust pipe. Switch

should trip off. Repeat procedure on other exhaust

pipe.

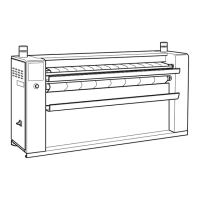

Feeding Ribbon Tension

Adjustment

To adjust the tension of the feeding ribbons, follow

these steps and refer to Figure 22.

1. Loosen the screws at both ends of the pick-up

table.

2. Carefully slide the pick-up table to adjust the

tension of the feeding ribbons.

NOTE: The feeding ribbons should wrap around

the feeding ribbon roller with enough tension to

turn without sliding, but not so tight as to become

stretched out.

3. When the correct tension has been reached,

tighten the screws.

IMPORTANT: Do not over-tighten the feeding

ribbons as this will cause rapid deterioration.

To avoid possible serious injury:

• ALWAYS shut off services to finisher

BEFORE doing ANY maintenance,

service, setup, adjustments or repair to

finisher.

• Shut off AND lock out ALL electric power

to finisher.

• Let heated surfaces cool.

• BE SURE moving parts are at a standstill.

• ALWAYS be careful to AVOID spring

loaded components when working inside

finisher.

ALL maintenance, service, etc. MUST be

performed ONLY by qualified service

personnel.

W549

WARNING

To AVOID possible serious injury,

BEFORE maintenance or repair tasks:

• Disconnect all utilities such as gas,

steam, and electricity.

Allow heated parts and surfaces to cool.

W544

WARNING

FWF4N

1 Screws

2 Pick-Up Table

3 Feeding Ribbons

Figure 22

Loading...

Loading...