4.3 FEEDING OUT

During mixing, the mixing chamber is separated from the feed out chamber by

a Variable Feed Control (VFC) or guillotine door, thus ensuring complete mixing.

The feed out chamber contains an auger which runs the entire length of the

machine.

When chopping/mixing is complete, the feed out tray should be set to the

required position, and the VFC door dropped, allowing the material to be swept

up by the paddles and pushed onto the auger – see gure 2. The VFC door

should be partially opened at rst, ¼ ways, and when feed is seen discharging

then 15-20 seconds should be allowed before opening the VFC door fully. Door

position and ground speed should be set/used to allow an even feed out rate.

4.4 MAINTENANCE

CAUTION:

The VFC door should only be opened or closed when

the PTO is engaged (paddles turning) when material is

in the machine.

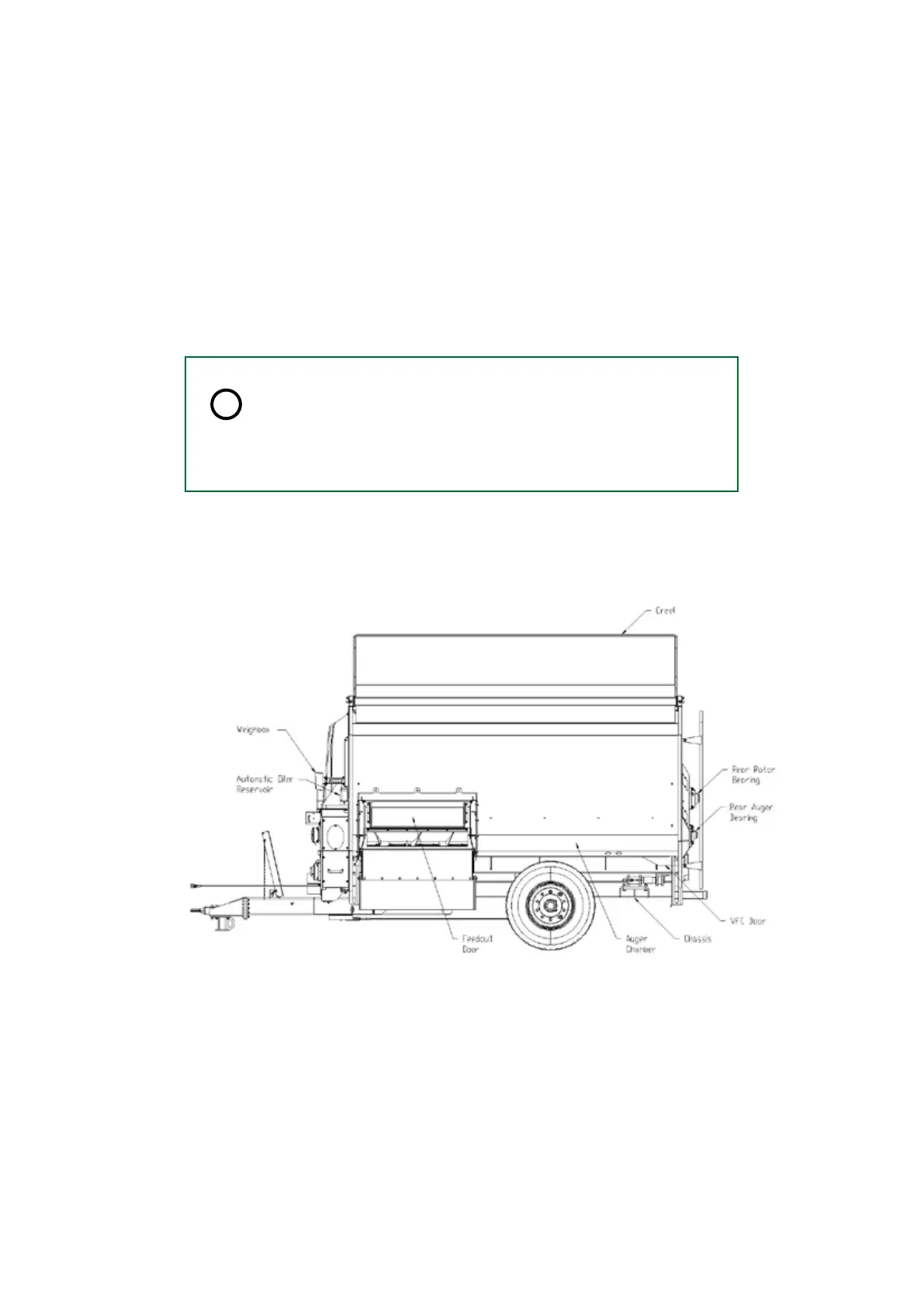

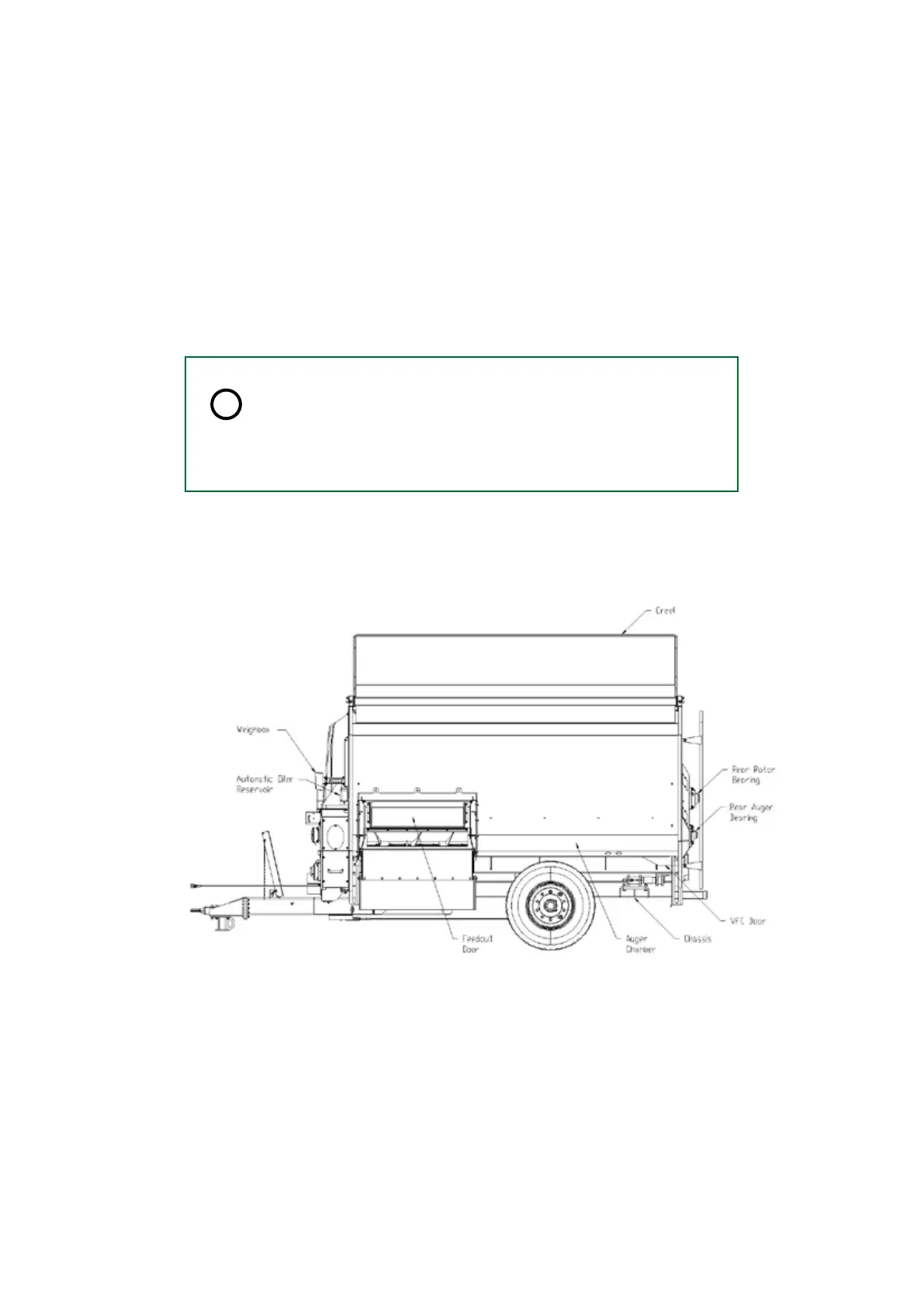

Figure 1: KEENAN MechFiber Mixer Wagon (BaleBlend Option Shown)

A properly operated and maintained KEENAN mixer wagon will give years of

trouble free operation. Regular maintenance of the machine is essential both

for long machine life and also to meet the warranty requirements. Refer

to instructions in maintenance section of this manual. Weekly cleaning of the

machine is recommended to prevent corrosion to the mixer body from old feed.

The level of cleaning required will depend on the material being mixed,

but any material which sits or lodges on the machine may both adversely

aect the operation of the machine and aect the quality of the mix if it

subsequently falls into the feeder during mixing. It is therefore essential

that routine cleaning and washing down of the feeder is completed.

8

Revision G04 July 2018

Loading...

Loading...