80 EAV64301 01/2015

Electromagnetic Compatibility

Limit Values

This product meets the EMC requirements according to the standard IEC 61800-3 if the measures

described in this manual are implemented during installation. If the selected composition (product itself,

mains filter, other accessories and measures) does not meet the requirements of category C1, the

following information applies as it appears in IEC 61800-3:

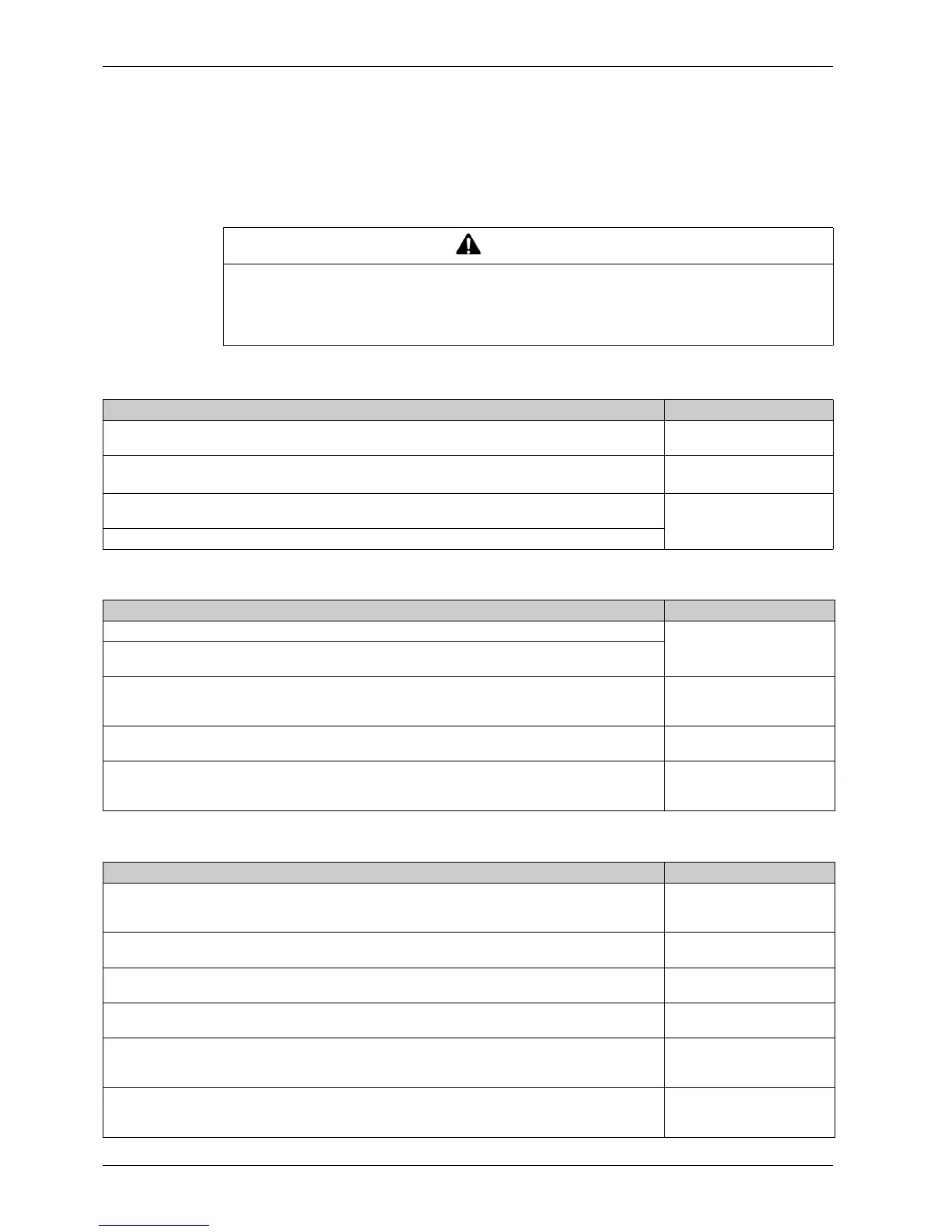

EMC requirements for the control cabinet

Shielded cables

Cable Installation

WARNING

RADIO INTERFERENCE

In a domestic environment this product may cause radio interference in which case supplementary

mitigation measures may be required.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EMC measures Objective

Use mounting plates with good electrical conductivity, connect large surface areas of metal parts, remove

paint from contact areas.

Good conductivity due to large

surface contact.

Ground the control cabinet, the control cabinet door and the mounting plate with ground straps or ground

wires. The conductor cross section must be at least 10 mm

2

(AWG 8).

Reduces emissions.

Fit switching devices such as power contactors, relays or solenoid valves with interference suppression units

or arc suppressors (for example, diodes, varistors, RC circuits).

Reduces mutual interference.

Install power components and control components separately.

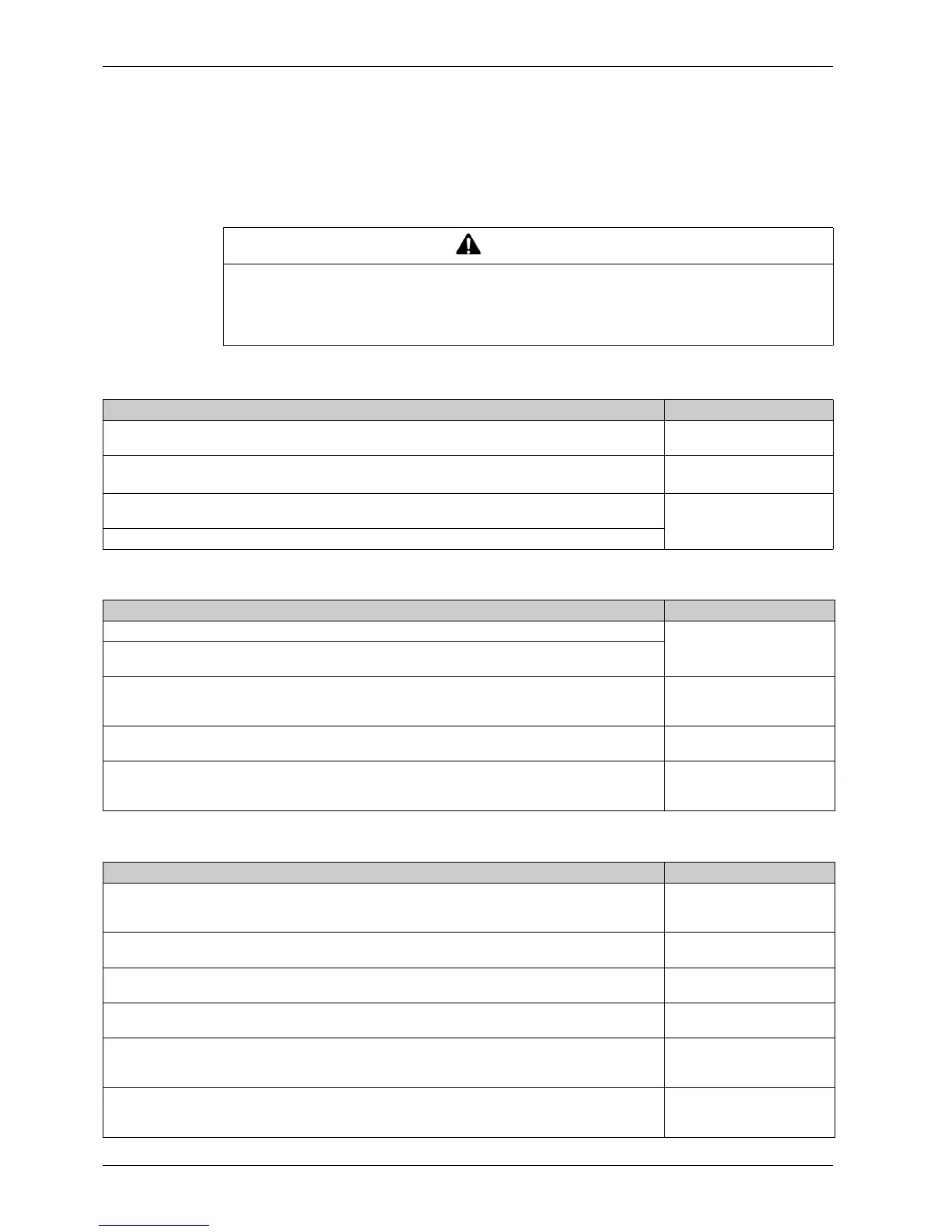

EMC measures Objective

Connect large surface areas of cable shields, use cable clamps and ground straps. Reduces emissions.

Use cable clamps to connect a large surface area of the shields of all shielded cables to the mounting plate

at the control cabinet entry.

Ground shields of digital signal wires at both ends by connecting them to a large surface area or via

conductive connector housings

Reduces interference affecting

the signal wires, reduces

emissions

Ground the shields of analog signal wires directly at the device (signal input); insulate the shield at the other

cable end or ground it via a capacitor (for example, 10 nF, 100 V or higher.

Reduces ground loops due to

low-frequency interference.

Use only shielded motor cables with copper braid and a coverage of at least 85%, ground a large surface

area of the shield at both ends.

Diverts interference currents in

a controlled way, reduces

emissions.

EMC measures Objective

Do not route fieldbus cables and signal wires in a single cable duct together with lines with DC and AC

voltages of more than 60 V. (Fieldbus cables, signal lines and analog lines may be in the same cable duct)

Recommendation: Use separate cable ducts at least 20 cm apart.

Reduces mutual interference.

Keep cables as short as possible. Do not install unnecessary cable loops, use short cables from the central

grounding point in the control cabinet to the external ground connection.

Reduces capacitive and

inductive interference.

Use equipotential bonding conductors in the following cases: wide-area installations, different voltage

supplies and installation across several buildings.

Reduces current in the cable

shield, reduces emissions.

Use fine stranded equipotential bonding conductors. Diverts high-frequency

interference currents

If motor and machine are not conductively connected, for example by an insulated flange or a connection

without surface contact, you must ground the motor with a ground strap or a ground wire. The conductor

cross section must be at least 10 mm2 (AWG 6).

Reduces emissions, increases

immunity.

Use twisted pair for the DC supply.

For digital and analog inputs use shielded twisted cables with a pitch of between 25...50 mm (1...2 in).

Reduces interference affecting

the signal cables, reduces

emissions.

Loading...

Loading...