Operating Instructions DC-xx13 and M31xx

961-00060 rev9 23/25

7 Trouble Shooting Guide

The following section has been prepared as a basic checklist to use in the event of the system

problem. The design and reliability of the products is such that power supply failure itself is extremely

rare.

More often than not, a system problem will be caused by a change in the overall process in which the

power supply is used. It is therefore VERY IMPORTANT to consider the variables that may effect the

welding process and to be sure that these are under control, before suspecting a problem with the

power supply.

Typical process changes maybe

1. An electrode change; dirty or damaged electrodes

2. Dimensional changes in product

3. Material quality, e.g. Oxide layer, substrate thickness etc..

4. Faulty weld heads

If these aspects have been considered, then the following checklist should be worked through. Most

machines provide a level of fault reporting with error codes and rudimentary help. Before making chan

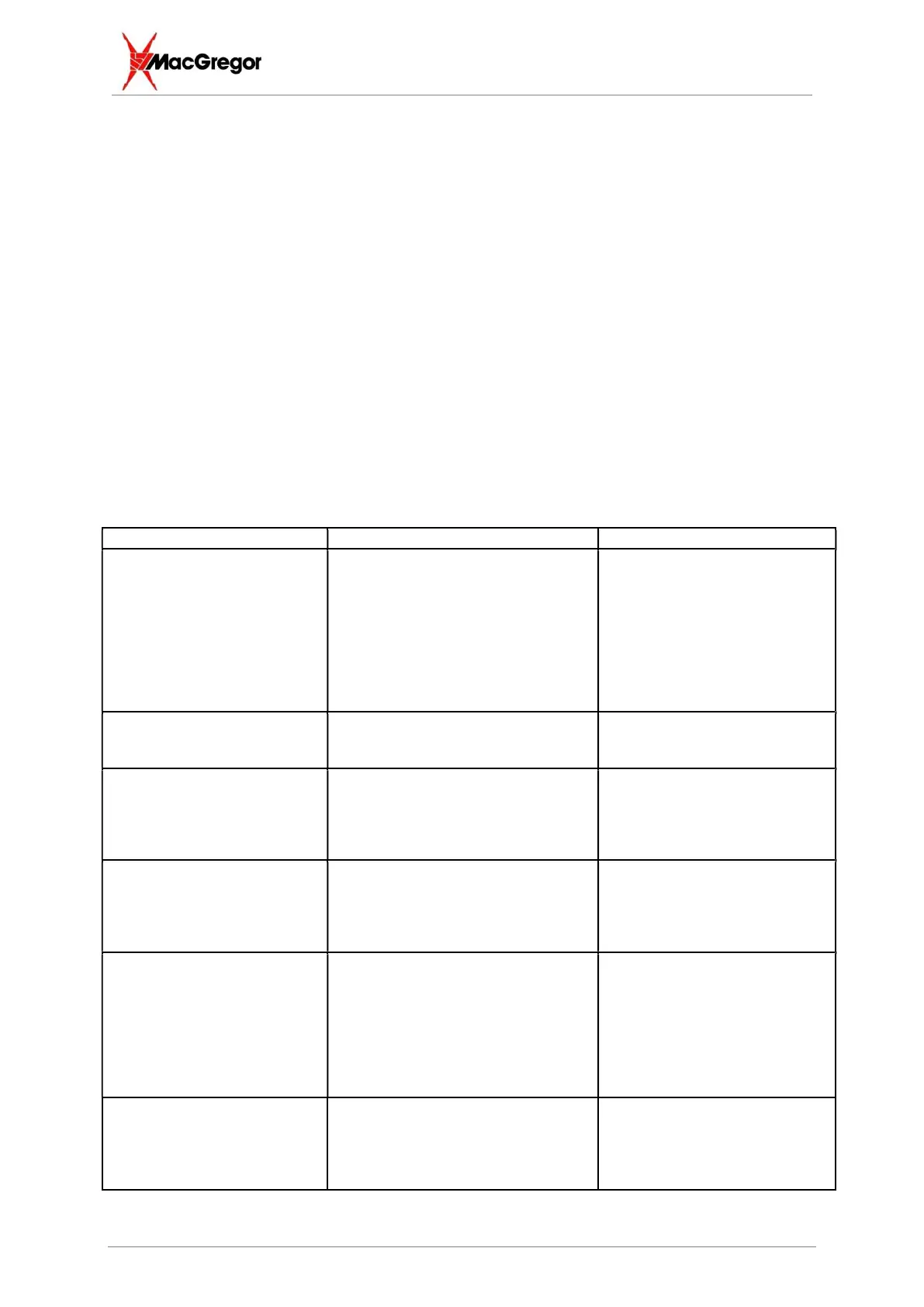

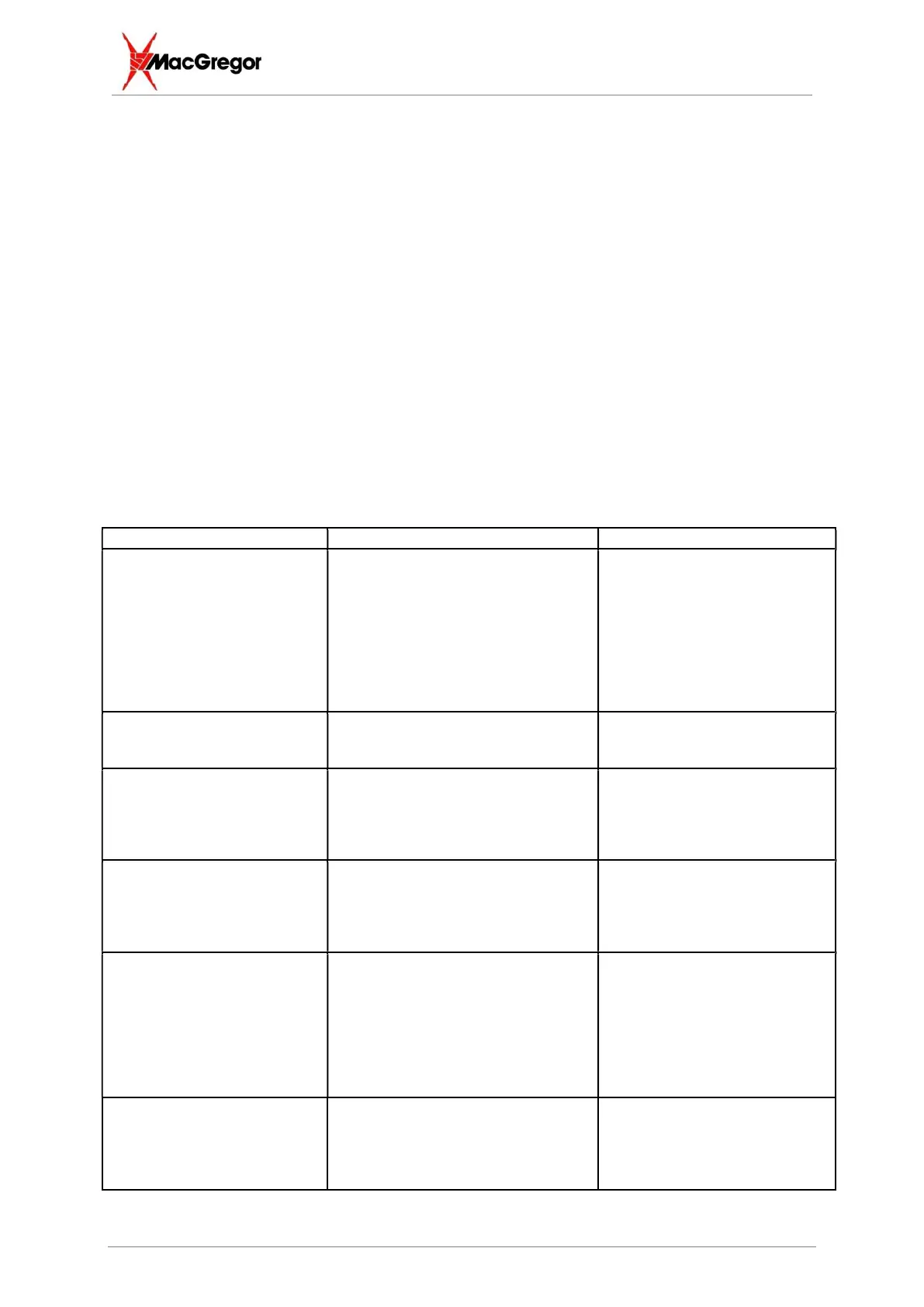

Is the power on indicator

illuminated ?

This LED illuminates to show the

machine is ON and that the internal

+24VDC supply is functioning

Check rear panel fuse (if fitted).

Disconnect ALL external

connections.

(It is quite common for external

wiring faults to cause the

+24VDC supply to be

overloaded)

Check mains fuse

Check mains supply to machine

Is the main display

illuminated?

The machine display will illuminate

ONLY if the +15V internal supply is

good

Check rear panel fuses

Check mains supply to machine

Check mains fuse

Machine is on, but no output The machine output will be inhibited

if the machine overheats or suffers a

feedback fault.

Clear the fault & inhibit

Allow machine to cool down and

investigate reasons for over

heating

Check output connections.

Machine is on, but no output

(using distribution electronics)

Loss of output maybe caused by

either the power supply or the

distribution electronics

If using distribution, disconnect

the distribution electronics and

connect a load across the

welder directly. Try a sample

weld pulse.

Machine continually produces

a HARDWARE/FEEDBACK

fault

This occurs when the machine loses

the measurement feedback used for

control - The most common problem

is broken voltage feedback wires.

Similar faults also occur when

electrodes have been replaced or

modified incorrectly.

A quick check for voltage

sensing feedback is to try a

weld with internal sensing by

disconnecting the leads and

fitting links or by unplugging the

voltage sensing jack socket.

Check electrode contact

Machine continually produces

a HARDWARE/FEEDBACK

fault

(using distribution electronics)

The fault must be traced to either the

power supply or the distribution

electronics.

If using distribution, disconnect

the distribution electronics and

connect a load across the

welder directly. Try a sample

weld pulse.

Loading...

Loading...