www.amico.com 23

Inspection and Maintenance

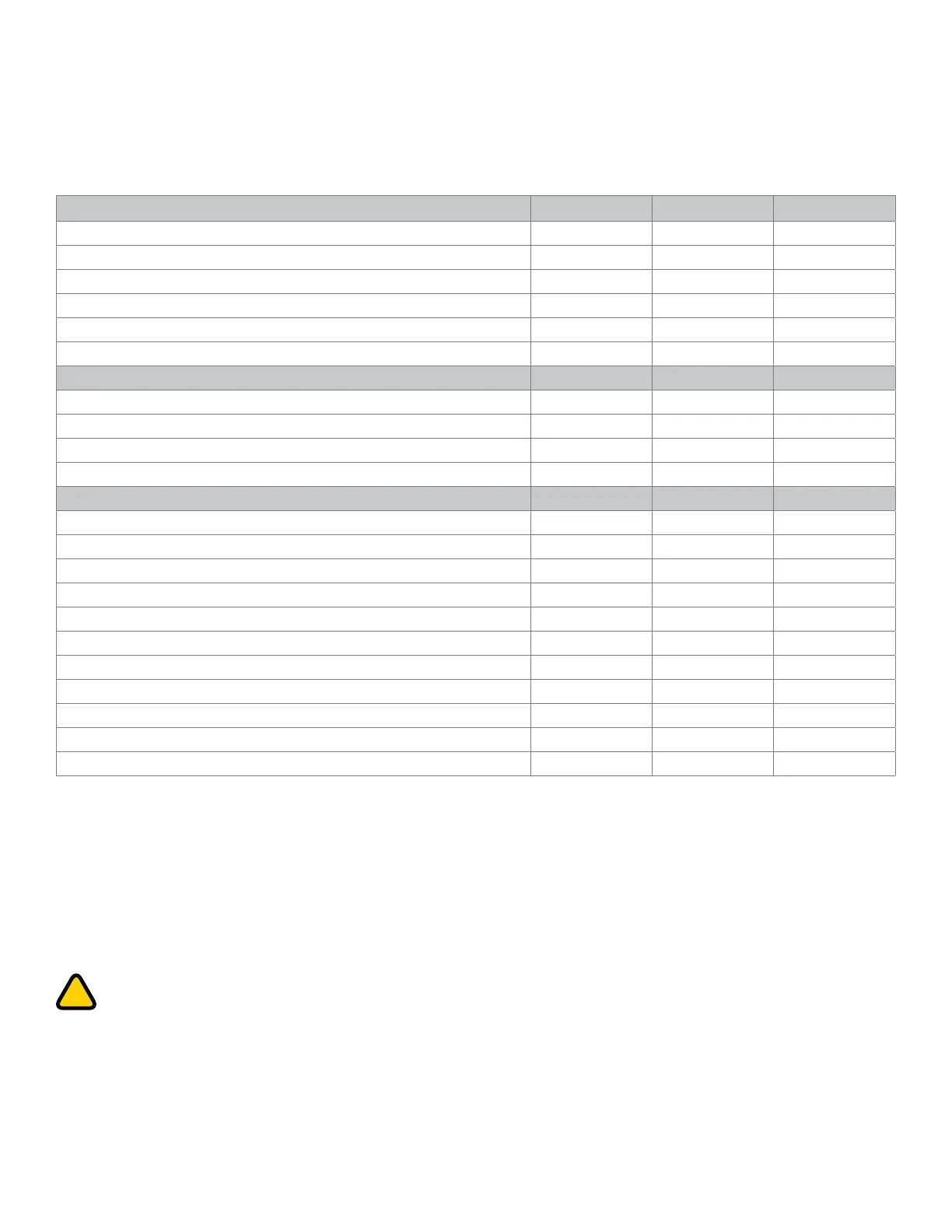

Prior to using the Amico GoLift, the inspections should be conducted per the following schedule:

Item Before Use Every Month Annual

GoLift

•

Ensure that end stops are installed

•

Inspect strap for wear or fraying

•

Ensure Batteries are charged

•

Inspect Carry Bar for damage or sharp edges or gaps in swivel pin area

•

Inspect the wheels in the trolley. Replace if damaged.

•

Sling

Check all straps for wear or fraying

•

Inspect the sling for any damage in the fabric

•

Ensure there are no loose threads in the stitching

•

Maintenance by a certified technician

Check the strap and replace only if frayed or damaged

•

Inspect the gearbox for any unusual noises

•

Inspect the carry bar components for any cracks

•

Inspect the gears for any broken or worn teeth

•

** Verify the overspeed cam is operating freely

•

Check emergency stop cord

•

** Check emergency lowering device

•

*Annual load test with SWL (maximum safe working load)

•

Ensure the end stops are installed

•

*Reapply grease to the gears

•

* In accordance to the ISO 10535 Standard “Hoists for the transfer of disabled persons – Requirements and test

methods” an inspection should be performed on the GoLift at least once a year. This inspection should be performed

by a qualified technician and should include a working load test of one (1) lifting cycle with the maximum load.

* Re-apply grease to the gears using the Amico certified grease. Can be bought from Amico.

** These two functions must be checked by a qualified technical to ensure the essential performance of the GoLift.

CAUTION: Do not operate the GoLift until any issues discovered during the inspection have been addressed

by a certified technician.

Loading...

Loading...