8

3.SAFETY

3.1 GENERAL WARNINGS

The operator must read paying the maximum

attention to the information written in this

Handbook, expressively about proper precautions

for Safety listed in this chapter.

It is indispensable for the operator to follow

the warnings list here below:

• Keep the machine & it’s working area clean

& ordered

• Provide appropriate containers to stock

moulding to be used.

• Use the Machine only in perfect psycho

physical condition

• Wear an adequate clothing to avoid obstacles

and/or dangerous entangles to/from the

machine

• Wear the individual protection gears

prescribed by this instructions handbook

• Do not remove or alter the warning plates

and adhesive signs

• Do not remove or elude the Machine Safety

Systems

• Keep the fingers away from the working area

• Disconnect the air pressure and power supply

during any maintenance intervention

• Keep the feet separated from the pedal during

Machine repair

3.3 INADVISABLE USE

The machine can not be used for:

• For uses different from those listed in 3.2

paragraph

• In an explosive or aggressive atmosphere,

where there is a high density of dust or

oily substances suspended in the air

• In flammable atmosphere

• Outside in all weather severity

• With disconnected electromagnetic

interblocks

• With electric bridges and/or mechanical

instruments leaving out machine parts or

functions

• For working materials not suitable with

machine characteristics

3.2 SCHEDULED USE

The Machine is designed and built to execute

junctions of frames.

The machine is projected for semi-automatic

operation (under operator control).

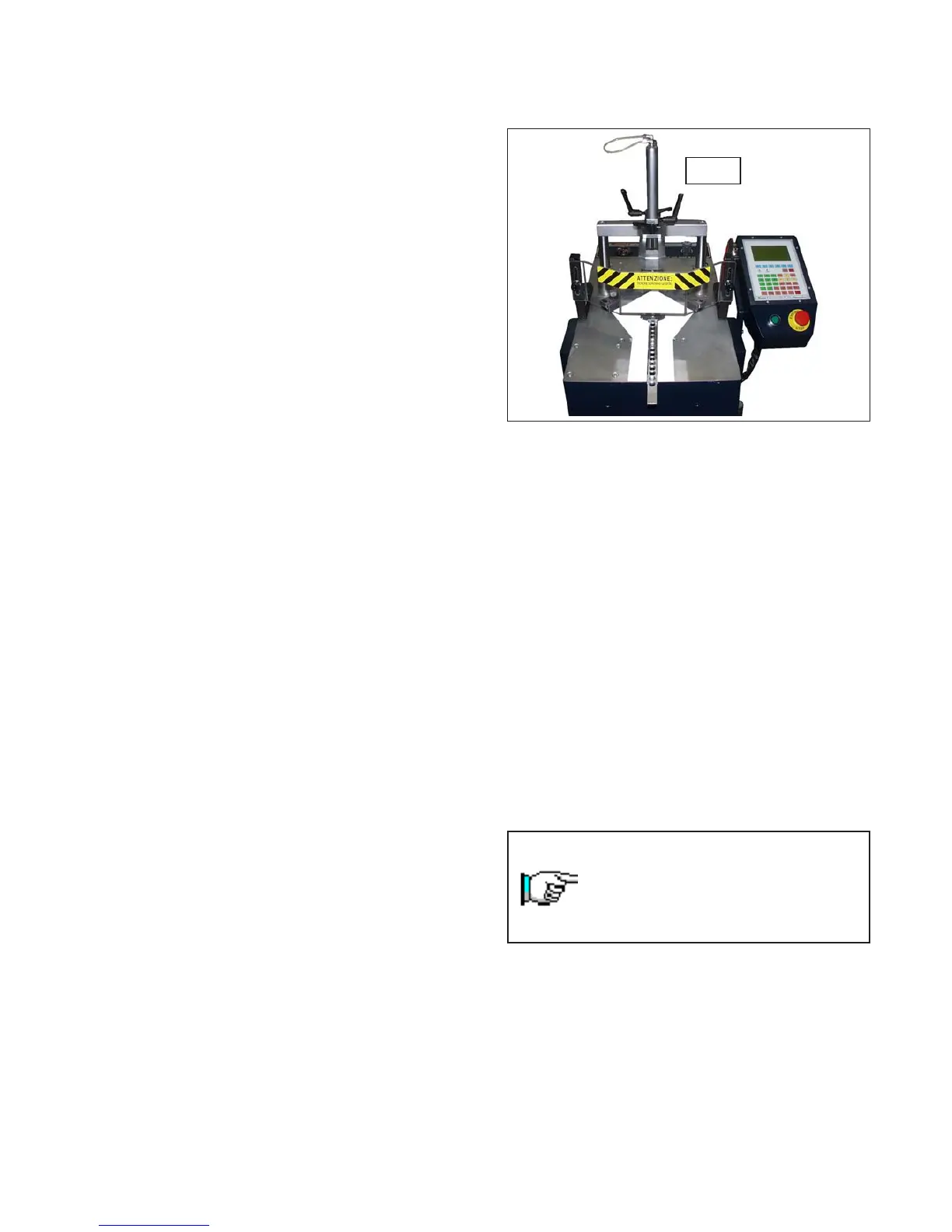

3.4 DANGEROUS AREAS

The area of frames assembly is defined as the

“working area”

The dangerous areas of machine, include the

movable parts and surrounding zones

3.5 PROTECTION DEVICES

The machine is equipped with adequate protections

for persons exposed to the risks due to the

transmission mobile elements, or movable organs

taking part in working (driver blade, horizontal

clamp, vertical clamp).

3.7 SAFE WORKING PROCEDURES

The other risks related with working are:

• Finger crushing in the vertical clamp working

area

• Finger crushing in the frontal clamp working

area

It is necessary to carefully adhere to the

following instructions:

1 Keep the fingers away from frontal and vertical

clamp working areas

2 Disconnect the air pressure and the power

supply during any maintenance interventions

3 Keep the foot away from the pedal during

machine maintenance.

3.6 STOP FUNCTIONS

The machine stop functions are the following:

- Stop Category 0.

- Stop Category 1.

STOP CATEGORY 0

It is obtained by disconnecting the fast clutch

fitting from the feed system (uncontrolled

stop).It is obtained by flipping the main switch

located on the floor stand.

STOP CATEGORY 1

Controlled stop obtained by lifting the foot

from the pedal which will not allow the v-nails

firing.

The machine is projected and

realized to eliminate any risk

connected with its use.

The user is requested to achieve

an adequate training to be

instructed by their distributor.

Dangerous area

Figure 3.4.A- Working area and dangerous zones

Loading...

Loading...