10

4.6 CONNECTIONS

To avoid any problems while starting up the

machine , it is sug gested to follow what is

described below.

4.6.1 Pneumatic connection

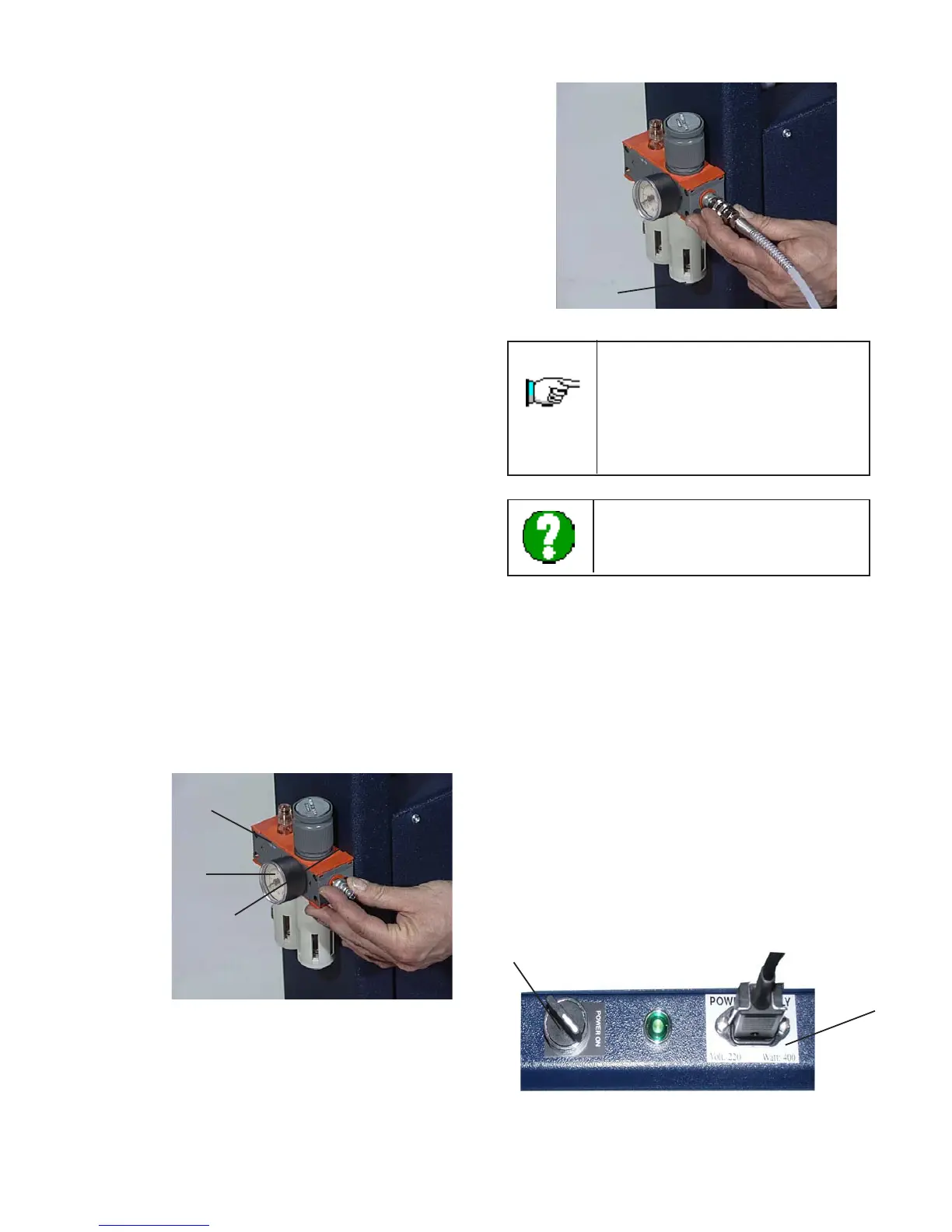

Unscrew the lubricator bowl out from the air

lte r lub ricator.”C”

Fill the bowl with lubricating oil up to the

level m ark.

Scre w t h e “A” pressure gauge on the air lter

Scre w t h e “B” fast clutch tting normally

supplied or another suitable with the erising

system. (See picture 3)

Connect the feed line to the tting. (See

picture 4)

In the lubricator it is

advisable to use lubricant type

CASTROL MAGNA GC 32 o r a n

eq u ivalent lubrican t. Don’tuse

generic lubricants !

The use of non-suitable lubricants

might damage the valves.

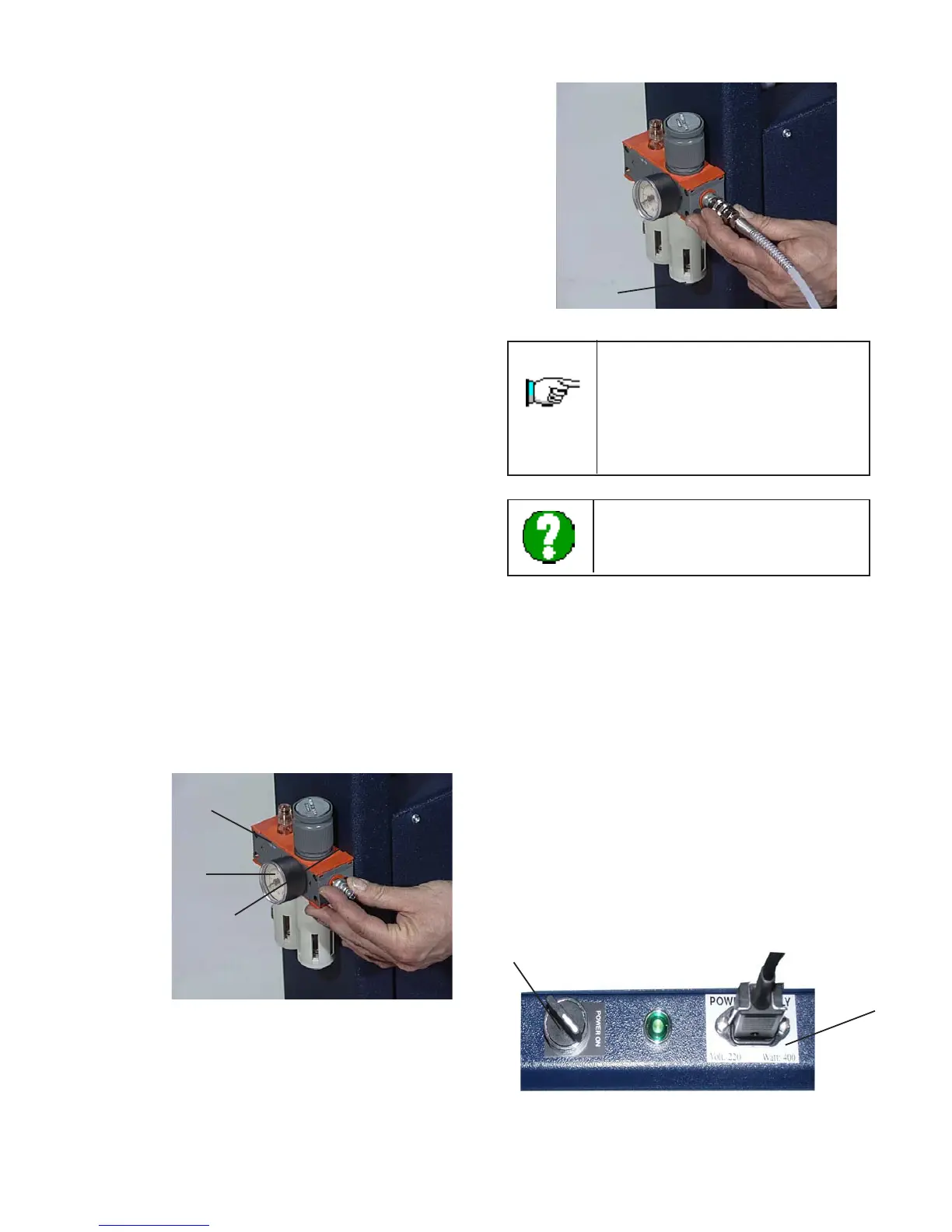

4.6.2 Electric connection

Check the network Voltage: it must be the same

of what indicated on machine cable (120 V).

Connect the power supplying cable to the plug

positioned on the machines rear side.

Avoid the use of long extension cables.

Pu t t he switch ( E ) on “1”which islocated on the oorstand

to switch on the machine.

Check that the green light next to the switch

is lit (if not, check the electric connections).

Rotate clockwise the emergency mushroom headed

button located on the keyboard.

Press the green button of the keyboard to

activate the keyboard controls.

4.3 PRELIMINARY ARRANGEMENTS

To install the machine it is necessary to prepare

a working area adequate to the machines

dimensions, lifting devices chosen and length

of mouldings to be worked.

4.4 UNPACKING

The machine is shipped on a wooden pallet,

packed into an appropriate carton and protected

with foam and polyurethane parts.

Remove the external packing and save it for

future use.

Check for any casual shipping damage and report

it immediately. Shipping damages or any other

defects must be reported to AMP within and

not later than 3 days from receipt of the

machine.

4.5 MACHINE POSITIONING

Position the machine in its working area.

Screw in the provided levelors to the oor

stand and level the machine by releasing or

tightening the levelors.

A

B

C

Picture 3

D

Picture 4

In order to eliminate the

condensation in the lter press

upwards on the “D” valve (see

picture 4).

D

E

Loading...

Loading...