CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-75

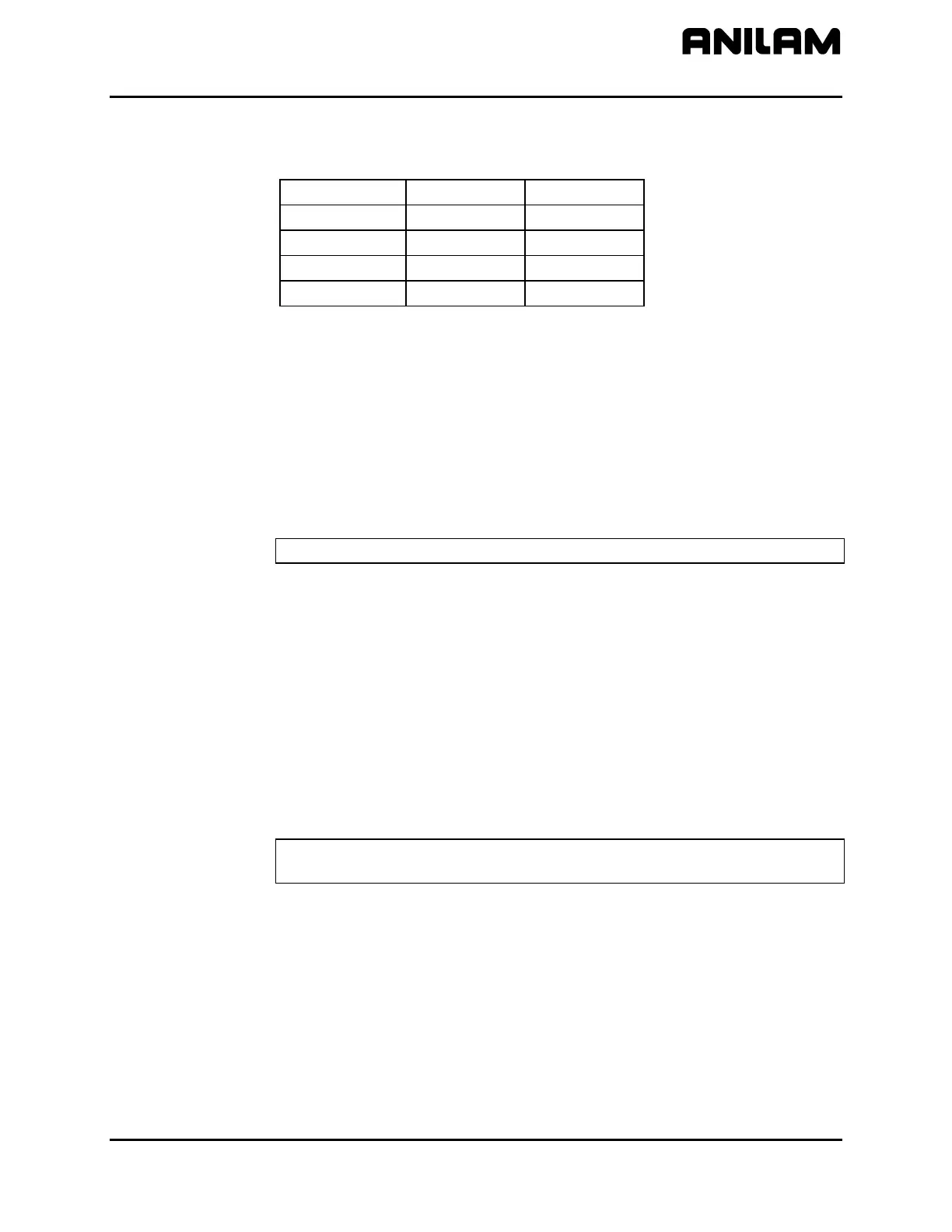

Refer to Table 2-3 for conversion values.

Table 2-3, Micron to Inch Conversion

0.5 Micron 0.0005 mm 0.00002”

1 Micron 0.001mm 0.00005”

2 Microns 0.002mm 0.0001”

5 Microns 0.005mm 0.0002”

10 Microns 0.010mm 0.0005”

Setting In-Position Tolerance

Reference machine constant parameters:

MC_2051: X In-position Tolerance Range

MC_2151: Y In-position Tolerance Range

MC_2251: Z In-position Tolerance Range

MC_2351: U In-position Tolerance Range

NOTE: Rapid moves always execute in In-Position Mode.

When the CNC has positioned the tool within the in-position tolerance of

the target, the CNC processes the next programmed move. At this time,

the CNC displays the in-position indicator. Specify the in-position

tolerance for each enabled axis in the Setup Utility.

[Default: 0.0100 mm]

When determining in-position tolerance:

For rotary encoders, tolerance is usually four times the machine

resolution (e.g., If machine resolution is 0.0002 in., the in-position

tolerance is 0.0008 in.). Use this as a benchmark from which to adjust

this value.

For linear encoders, tolerance equals the resolution of the linear encoder.

NOTE: In-position tolerance must be smaller than Continuous path

tolerance.

Loading...

Loading...