CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-87

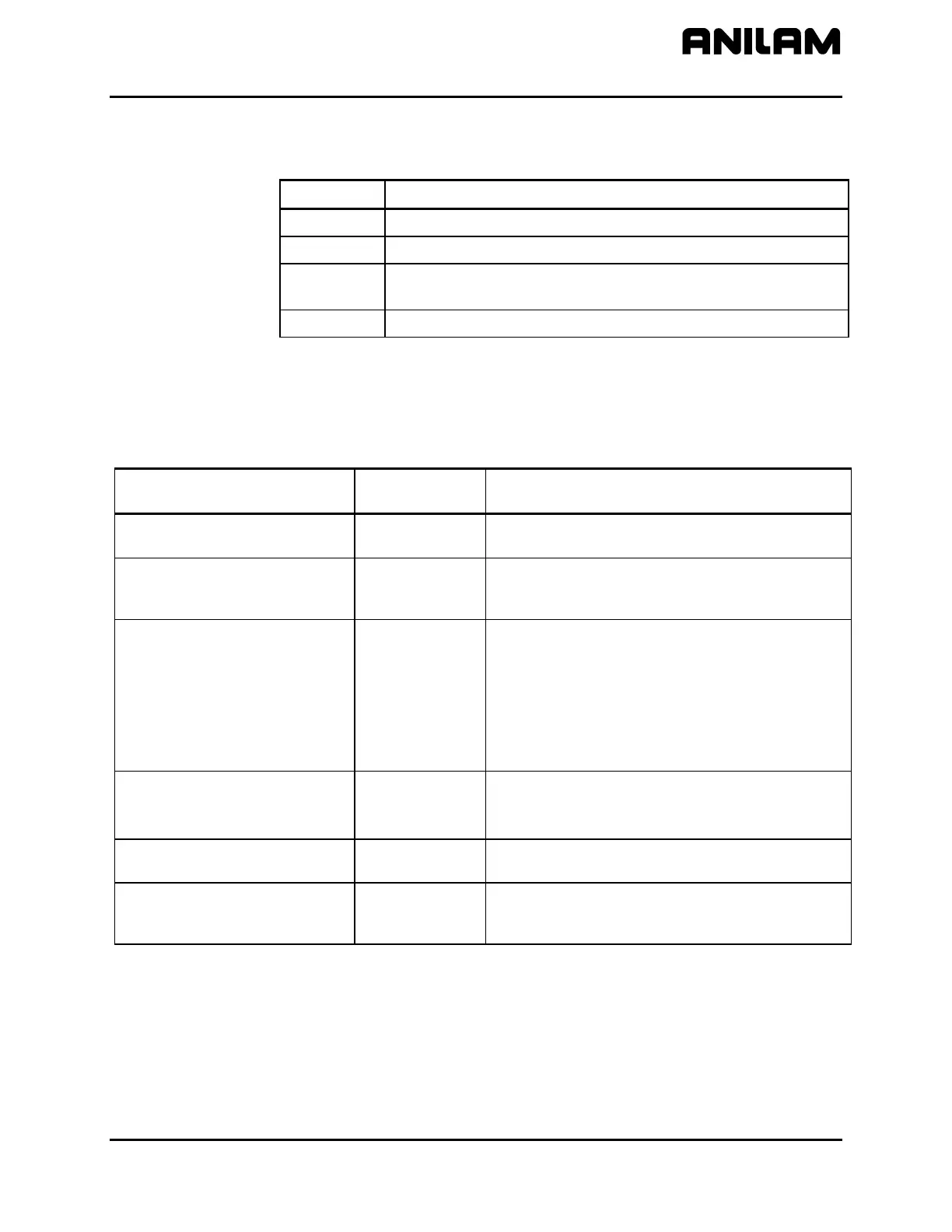

The available activation options are listed in Table 2-7.

Table 2-7, Tool Setup Activation Options

Setting Description

No Function is not used.

On Tn Function activates only when a tool is activated (T-Word).

On M6 Function activates only when Tool Changer M-function

(M6) activated.

Both Function activates when a tool number or M6 is activated.

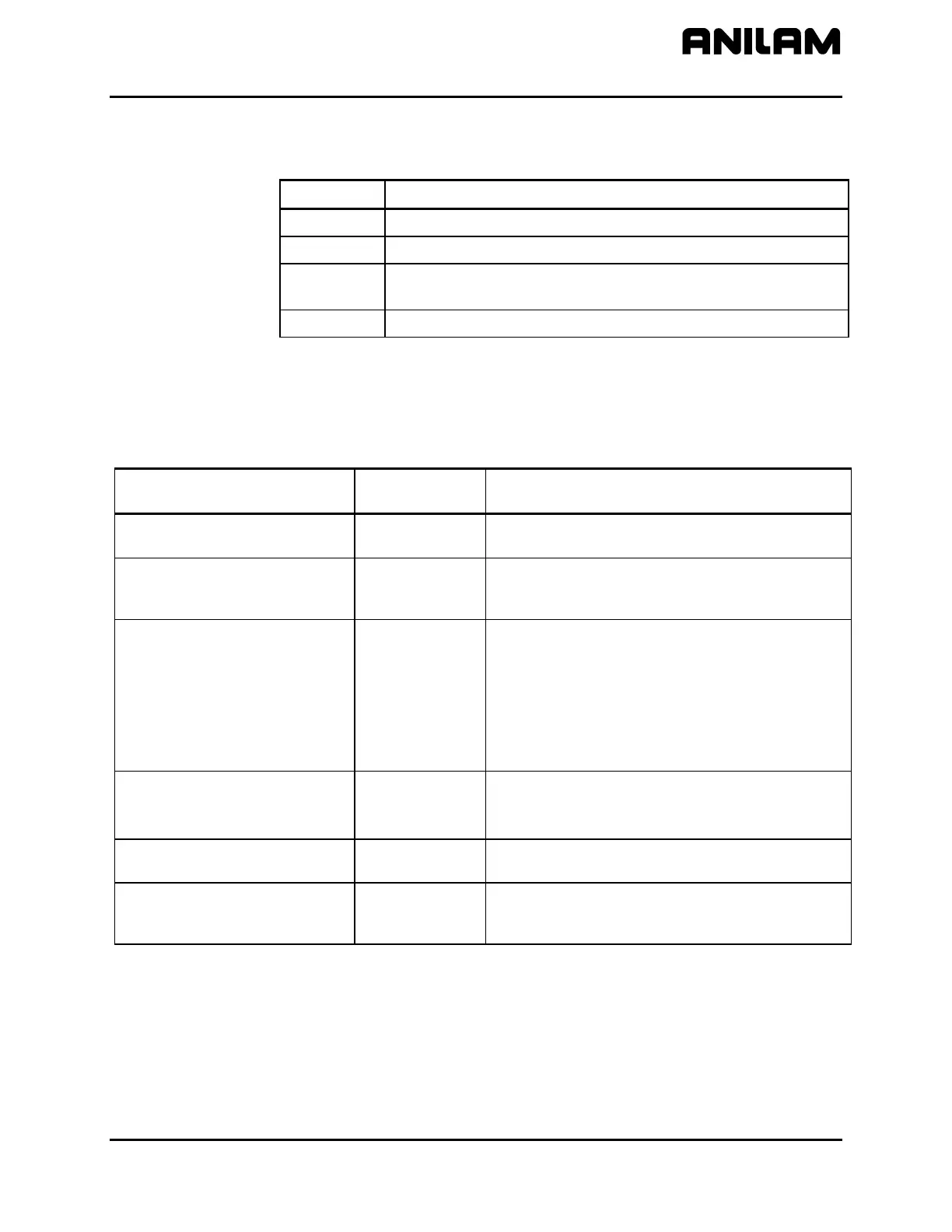

Manual Tool Change Operation

For manual tool change operations (that is, when a tool changer is not

being used), use the settings specified in Table 2-8.

Table 2-8, Manual Tool Change Settings

Manual Tool Change

Parameters

Required

Setting

Description

MC_5000: Activate tool-length

offset

On Tn Tool-Length Offset activates upon completion of a

T-word command to the Programmable Controller.

MC_5001: Output signal

On Tn Refers to T-code data being sent to the

Programmable Interface. Select On Tn to enable

the output signal when the T-code activates.

MC_5006: Stop program

execution

No or On Tn Halts the running program until given a Cycle Start

from the Manual Panel. For manual tool change

operations using a Programmable Controller, set

this selection to No (disabled). For manual tool

change operations without a Programmable

Controller, set to On Tn. The CNC will hold

program run and display a message. Press

START

to resume program run.

MC_5007: Tool changer

installed

None

Set to None (disabled). Use this selection to

enable closed loop orientation of the spindle during

tool changer operation.

MC_5011: Number of digits in

T word

4 Format of T-words (Txxxx).

MC_5015: Force spindle off

during tool change

Yes Forces spindle to be off before processing a tool

change command. If spindle On, the CNC will

generate an error message.

Loading...

Loading...