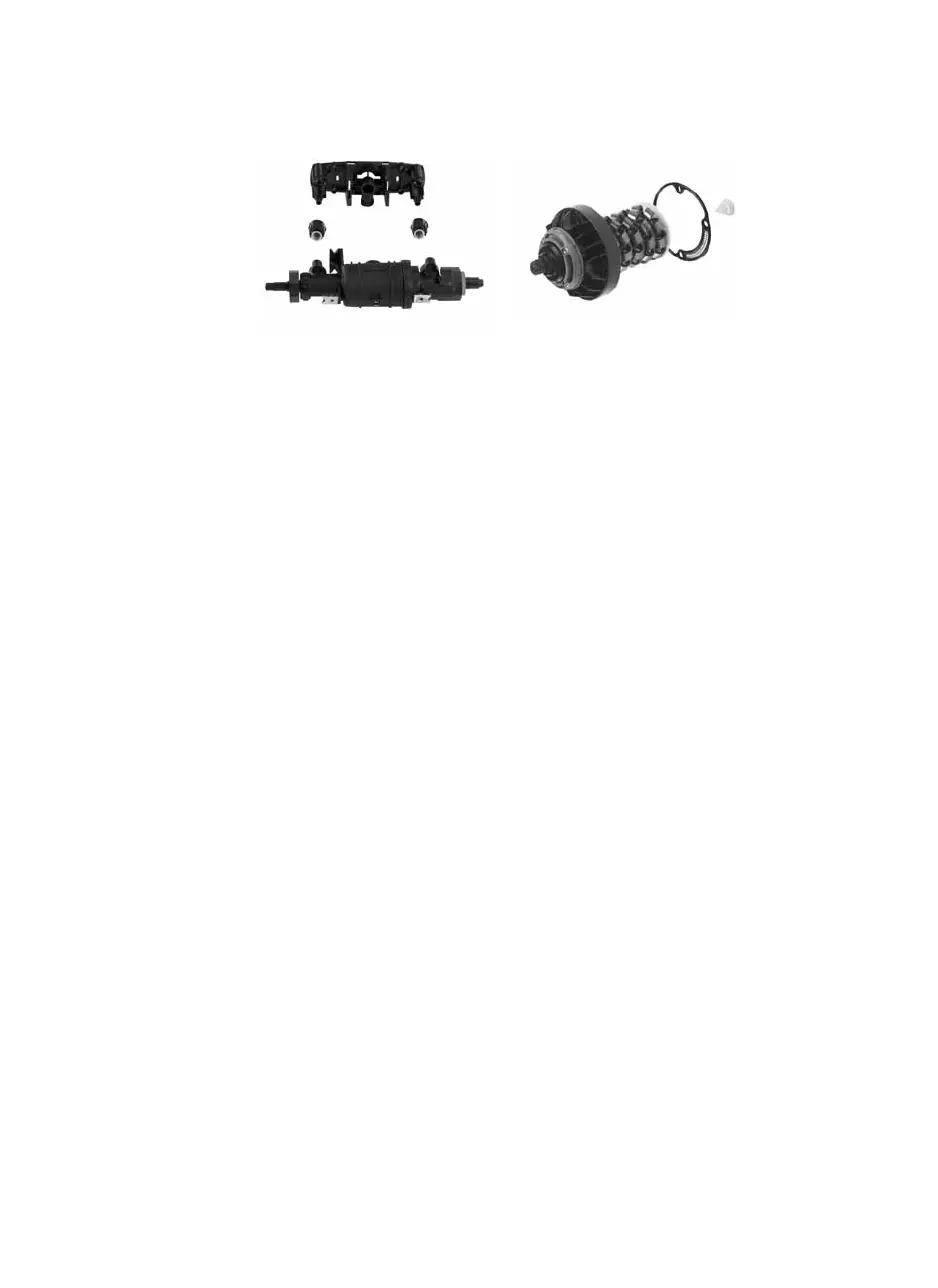

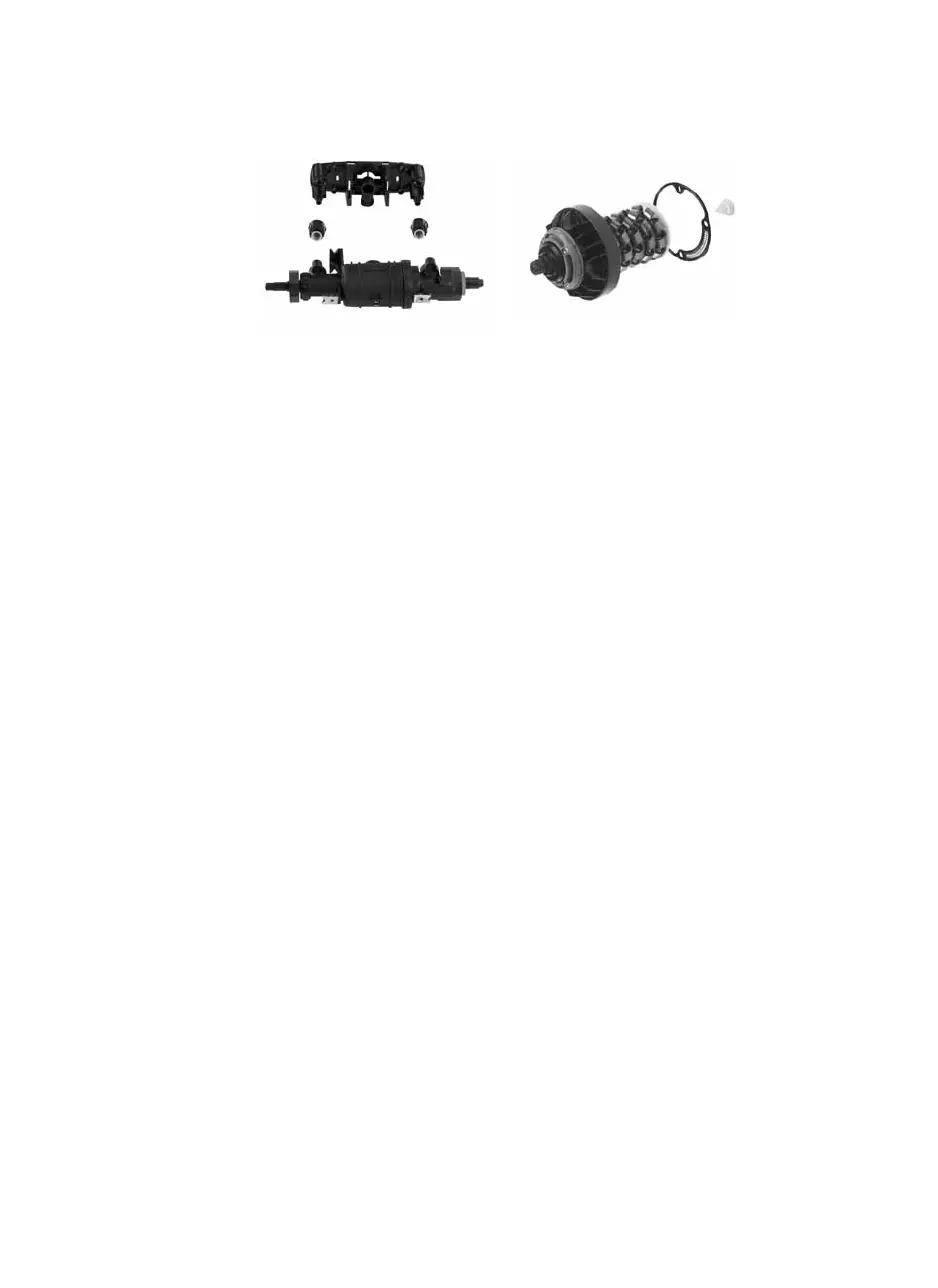

Filters

To ensure optimum ongoing performance, the ‘CARTRIDGE’ control mechanism is protected by a two part filter system in the

internal waterways. Debris accumulation may result in progressively reduced flow through the showerhead and noisy operation.

As this condition is not covered by our standard warranty terms, it is suggested that the cartridge is removed and the filters checked

by a competent person. In the event of any difficulties please contact the Aqualisa customer helpline for assistance.

Isolating valves

Suitable isolation valves such as gate valves must be fitted to both supplies in accordance with current Water Supply Regulations and

our terms of warranty. Due to their restrictive characteristics, stopcocks and ball type valves that reduce the pipe bore size must not

be used on gravity or pumped installations.

Pressures

Opto shower valves are designed to control static pressure up to 10 bar. Where pressures are likely to exceed 10 bar, a pressure

reducing valve (PRV) must be fitted into the incoming mains supply. A setting of 3 bar is recommended. It should be noted that

daytime pressures approaching 8 bar can rise above the stated maximum overnight.

Opto shower valves are not suitable for mixed supply systems e.g. Gravity hot and mains cold.

Gravity systems

Services must be installed according to good plumbing practice having regard to pipe sizing, long pipe runs and low-head situations.

The cold supply for the valve assembly must be taken directly from the cold storage system.

The hot supply may be taken from the vent/draw off pipe of the hot water cylinder at a point below the cylinder connection or

alternatively from the underside of the horizontal draw off. Rising pipe work must not be connected into the horizontal draw off from

the cylinder or to any point in the vent/draw off pipe above the cylinder connection.

CYLINDER TEMPERATURE IN EXCESS OF 65ºC MAY RESULT IN POOR SHOWER PERFORMANCE.

To minimise pressure loss we recommend that the hot and cold supplies are run in 22mm as close as reasonably possible to the

mixing valve before reducing to 15mm.

Siting

For optimum performance, with gravity fed systems, the distance between the bottom of the storage cistern and the shower head

should not be less than 1m (when using an adjustable height shower head). If using a fixed head, the highest point of the pipe work

must be not less than 1m below the underside of the cistern. Please refer to the system layout on page 20.

Pump installation

UNDER NO CIRCUMSTANCES MUST A PUMP BE FITTED DIRECTLY TO THE WATER MAIN.

A pump must only be used to boost the pressure from tank-fed supplies. A typical layout is shown on page 20.

Stored water capacities

The minimum capacity of the cold storage cistern should not be less than 225 litres (50 gallons). The capacity of the hot cylinder

must be capable of meeting the anticipated demand.

5

Loading...

Loading...