TECHNICAL AREA

/ 46

2. 8 RESET MENU’ 2

2. 8. 0 Reset Factory Settings Reset OK = yes

ESC = no

To reset all default parameter settings, press the

OK button

2. 11 BOILER SETTINGS

2. 11. 0 Gas start offset adj from 0 to 30 9

2. 11. 1 Gas Control Offset from 0 to 190 88

2. 11. 2 Flue Duct Adj from 0 to 20 (%) 0

2. 11. 3 Enable standby

calibration

0 = OFF

1 = ON

1

2. 11. 4 Enable calibration CH

switch

0 = OFF

1 = ON

0

2. 11. 5 Enable DHW

calibrataion threshold

temperature

0 = OFF

1 = ON

1

2. 11. 6 DHW ignition threshold from 0 to 5 (°C) 0

2. 12 ADVANCED SETTINGS 2

2. 12. 1 Max DHW adjustable

from 0 to 100 (%)

100

4 ZONE 1 PARAMETERS

4. 0 SETPOINT

4. 0. 2 T set Zone 1 from 35 to 82 (°C)

(high temperature)

70

from 20 to 45 (°C)

(low temperature)

25

To set only with Fixed Flow Temperaure (see

421)

4. 2 ZONE 1 SETTINGS

4. 2. 0 Zone 1 Temperature

range

0 = from 20 to

45°C

(low temperature)

1 = from 35 to 82°C

(high temperature)

1

4. 2. 1 Thermoregulation

To enabled

thermoregulation press

Auto button.

On the dispaly will

appear the symbol

AUTO

0 = Fixed Flow

Temperature

1 = Basic

Thermoregulation

2 = Room Temp

only

3 = Outdoor Temp.

only

4 = Room +

outdoor

Temp.

1

menu

sub-menu

parameter

description value

default

setings

menu

sub-menu

parameter

description value

default

setings

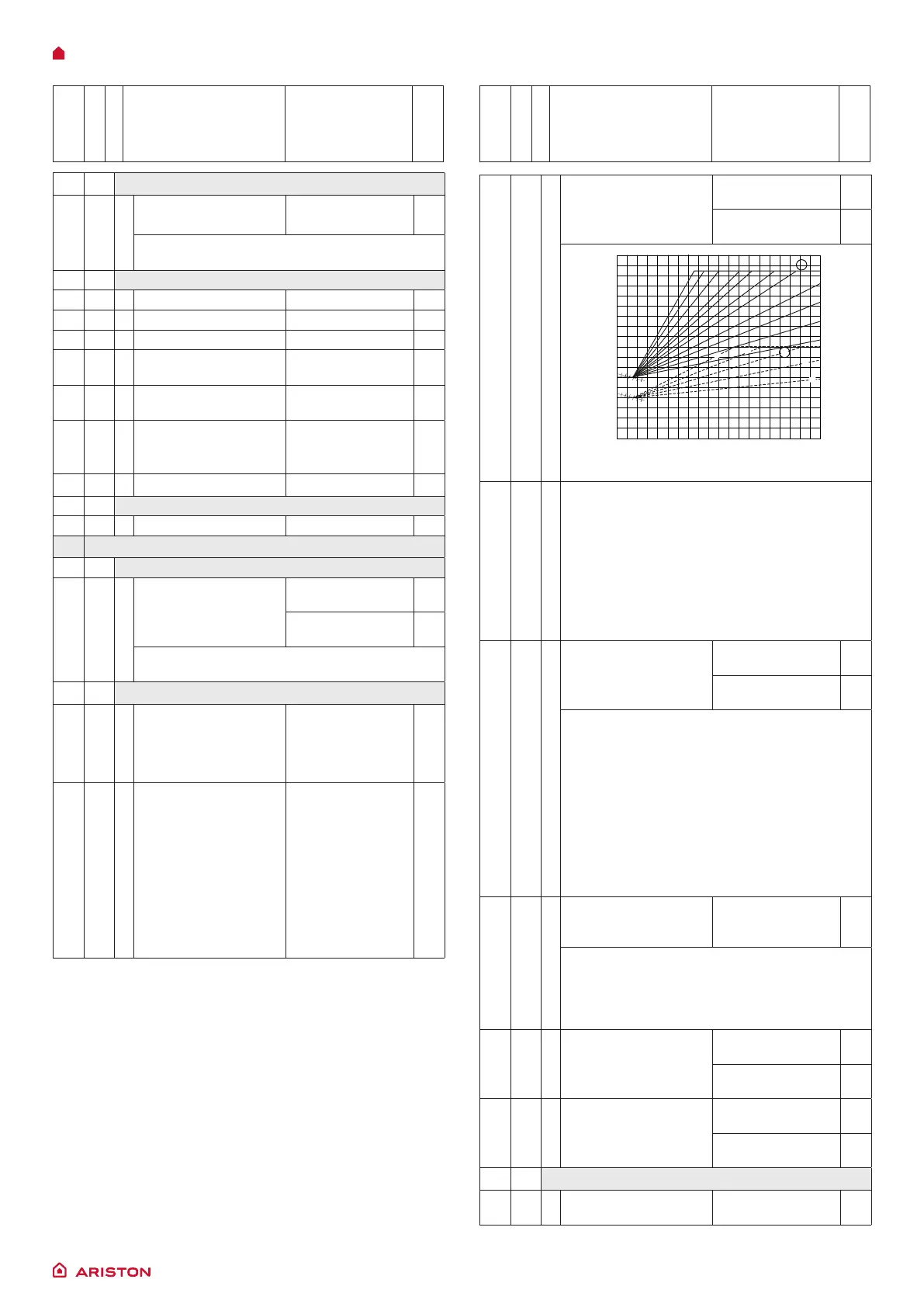

4. 2. 2 Slope from 1.0 to 3.5

(high temperature)

1.3

from 0.2 to 1.0

(low temperature)

0.6

°C

°C

Flow Temperature

Low temperature High temperature

External temperature

Ambiente temperature

setting value

23

23

21

21

19

19

30

20

10

0

40

50

60

70

80

90

°C

510152025

3.5

3.0

2.5

2.0

1.8

1.5

1.3

0.8

1.0

0.6

0.4

0 -5 -10 -15 -20 -25 °C

0.8

0.6

1.0

0.4

0.2

When an outdoor sensor is used, the boiler

calculates the most suitable delivery

temperature, taking into account the outside

temperature and type of system.

The type of curve should be selected in

correspondence with the projected temperature

of the system and the nature of the dispersions

present in the structure.

For high-temperature systems, one of the curves

depicted below may be chosen.

4.

2. 3 Offset

Auto Function active

from - 14 to + 14 (°C)

(high temperature)

0

from - 7 to + 7 (°C)

(low temperature)

0

To adapt the heating curve to the system

requirements, shift the curve in parallel so that

the calculated ow temperature is modied, in

addition to the room temperature.

By accessing the parameter and pressing the

button b, it is possible to shift the curve in a

parallel direction. The shifting value can be read

on the display: from -14 to +14 for high-temperature

devices, or from -7 to 7 for low-temperature

devices. Each step corresponds to a 1°C increase/

decrease In the ow temperature with respect to

the set-point value.

4. 2. 4 Room Inuence

Proportional

Auto Function active

from 0 to 20 20

If setted = 0 the room temperature doesn’t

inuence the calculation of the set-point.

If setted = 20, the room temperature has the

maximun inuence to calculate the set-point

- only active when the BUS device is connected

4. 2. 5 Maximum CH

Temperature Zone 1

from 35 to 82 °C

(Param. 420 = 1)

82

from 20 to 45 °C

(Param. 420 = 0)

45

4. 2. 6 Minimum CH

Temperature Zone 1

from 35 to 82 °C

(Param. 420 = 1)

35

from 20 to 45 °C

(Param. 420 = 0)

20

4. 3 Z1 DIAGNOSTICS

4. 3. 4 Heat request Zone 1 0 = OFF

1 = ON

Loading...

Loading...