TECHNICAL AREA

/ 43

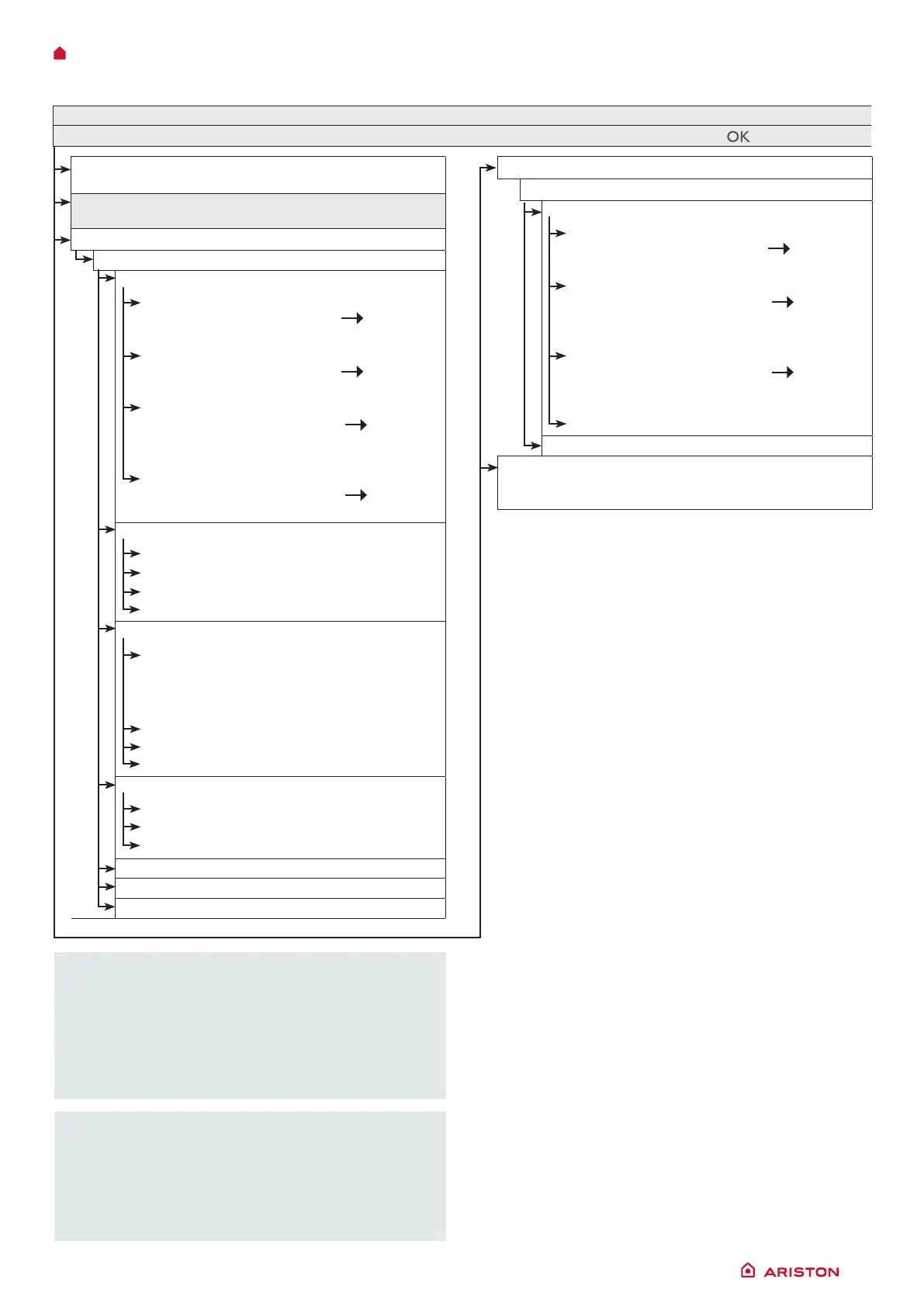

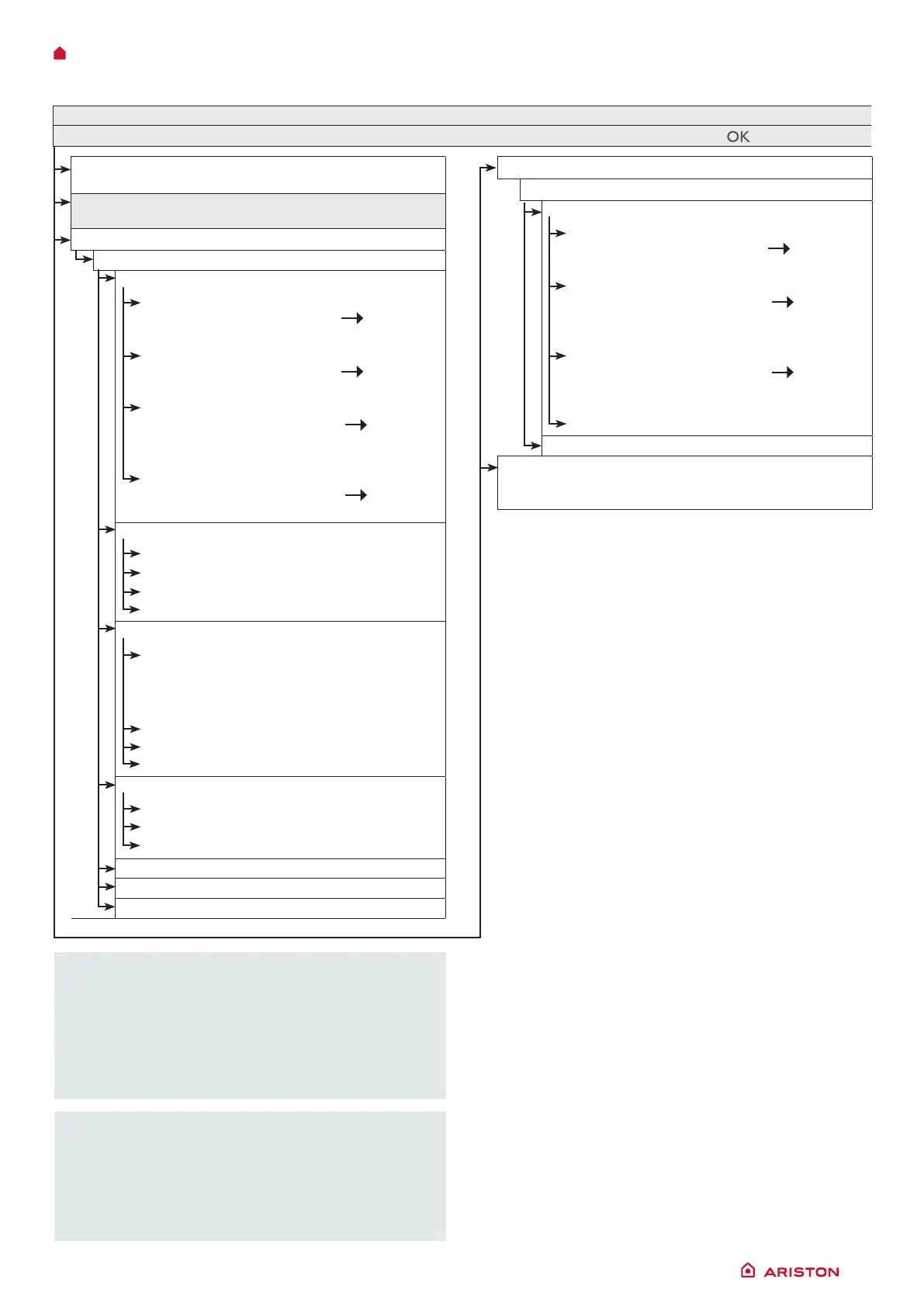

COMPLETE MENU STRUCTURE

Tecnical Area

Service code (reserved for qualied technicians) - Press the programming key b > to select 234 and press the button .

Language, date and time - Follow the instructions of the

display. Press OK button at each entry to save

COMPLETE MENU - The parameters relating to each

individual menu are listed in the following pages.

Conguration Wizard

Boiler

Conguration parameters

Gas Parameter

Direct access to the parameters 220 - 230 -

231 - 232 - 233 - 234 - 270

Settings

Direct access to the parameters 220 - 231 -

223 - 238 - 245 - 246

Visualization

Direct access to the parameters

821 - 822

- 823 - 824 - 825 - 827 - 830 - 831 - 832 - 833 - 840 -

835 - 874

Zone

Direct access to the parameters 402 - 502 -

602 - 420 - 520 - 620 - 434 - 534 - 634 - 830

Guided procedures

System Filling

System air purge

Exhaust fumes analysis

CO2 calibration

Service options

Service Center Data - To insert the name and

phone number of Service Center

The data appears in the display in case

of error

Enable service warnings

Service warning reset

Months remaining before Service

Test mode

Pump test

3 way valve Test

Fan test

Parametrization (see NOTE 1)

CH ow rate (see NOTE 2)

DHW ow rate reference (see NOTE 2)

NOTE 2 - Flow Rate Functions

Through the Flow Rate Functions it’s possible to check circulation

in different conditions. The DHW ow rate function can be used to

detect obstructions that reduce the ow rate value of the internal

boiler circuit (i.e. due to plate heat exchanger clogging). Thanks to

CH ow rate function it’s possible to perform the central heating

balancing.

NOTE 1 -

Parametrization

PARAMETERS BACK-UP FOR PCB AND DISPLAY REPLACEMENT

This function enable the boiler to automatically store, each

2 hours, the parameters back-up in the display internal

ash memory. Thanks to this function during the PCB

replacement is possible restore the previous parameters

setting. Read the instructions manual for changing the Main

PCB, Display PCB or Display.

Service

Boiler

Conguration parameters

Gas parameter

Direct access to the parameters 220 - 230 -

231 - 232 - 233 - 234 - 270

Visualization

Direct access to the parameters 821 - 822

- 824 - 825 - 827 - 830 - 831 - 832 - 833 - 840 -

835

Boiler PCB change

Direct access to the parameters 220 - 226

- 228 -229 - 231 - 232 - 233 - 234 - 247 - 250 -

253

Automatic Calibration - see page 18

Pump parameter - Reset value

Faults - The display shows the last 10 errors with details of

the code, description and date.

Turn the encoder to scroll the errors

Loading...

Loading...