COMMISSIONING

/ 32

Wi-Fi bo

Initializing.......

Start-up procedure

Press the ON/OFF button on the control panel to switch on the

boiler: the display will light up.

The initialisation procedure - indicated by the bar - begins.

Once the procedure is completed, the display will visualise

the temperatures set for the central heating and domestic hot

water circuits (display conguration: boiler base).

The boiler will request the setting of the date, time, language

and heating zone. Proceed as indicated in the USER MENU -

see the User’s Manual.

00/00/00

Press OK to enter Menu

00:00

42°

70°

1,5 bar

FIRST IGNITION

PERFORM THE SYSTEM AIR PURGE AND THE AUTOMATIC

CALIBRATION

1. Make sure that:

- The gas valve is open;

- The electrical connection has been properly carried out.

Make sure that, in any case, the green/yellow earthing

wire is connected to an efcient earthing system;

- loosen (unscrewing) the cap on the automatic air relief

valve;

- The exhaust duct for combustion products should be

suitable and free from any obstructions

IMPORTANT!

DURING THE CALIBRATION

PROCEDURE AND MEASUREMENT OF

THE CO

2

VALUE, IT’S IMPORTANT THAT

THE BOILER WORKS WITH THE FRONT

COVER CLOSED AND THE AIR/ FUMES

DUCTS FULLY ASSEMBLED.

- Any necessary ventilation inlets in the room should be

open (type B installation).

- Check whether the siphon contains water; if not, it must

be relled. If necessary, open the manual air vent on the

main exchanger until complete lling.

N.B.: if the boiler will not be used for

long periods, the siphon should be lled

before the boiler is started up again. It is

dangerous not to rell the siphon as fumes

may be released into the environment.

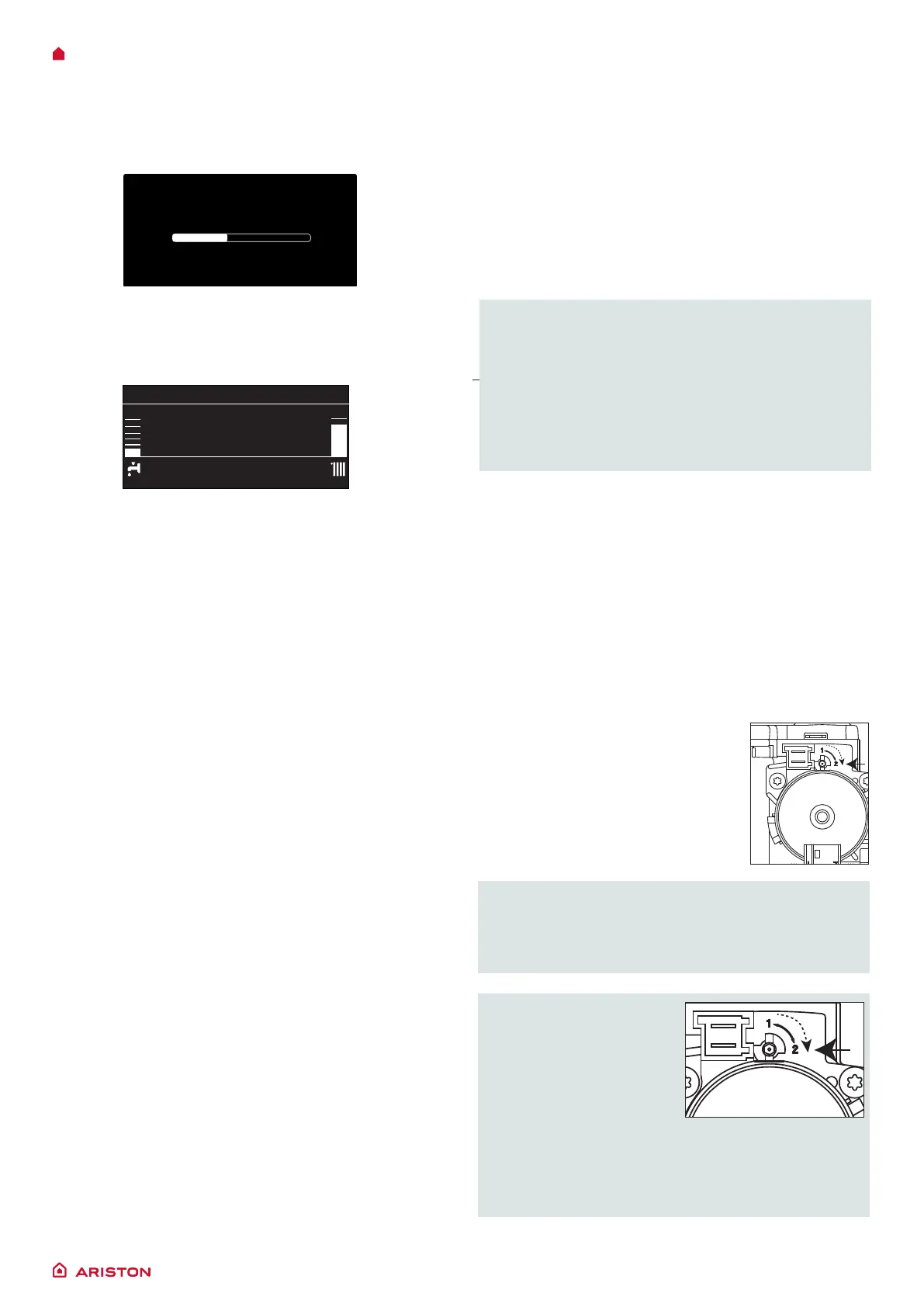

2. Supply static pressure check

Loosen the screw 1 and insert the

pressure gauge connection pipe into

the pipe tap.

The supply pressure should

correspond to the value established

in relation to the type of gas, for which

the boiler is designed see Table

summarising changes.

ATTENTION!!

THE BOILER CAN NOT BE ACTIVATED IF THE

PRESSURE IS NOT CORRESPONDING TO THE

TABLE SUMMARISING CHANGES

ATTENTION!!

THE BOILER IS FACTORY

SETTED ON NATURAL

GAS.

IF IS NECESSARY TO

CHANGE GAS TYPE

DURING THE FIRST

AUTOMATIC CALIBRATION, TURN THE SCREW TO

POSITION 2 FOR LPG.

POSITION 1 = NATURAL GAS

POSITION 2 = LPG

Loading...

Loading...