2. Operate actuator using push buttons OPEN, STOP, CLOSE.

➥

The limit switching is set correctly if (default indication):

- the yellow indication light/LED1 is illuminated in end position CLOSED

- the green indication light/LED5 is illuminated in end position OPEN

- the indication lights go out after travelling into opposite direction.

➥

The limit switching is set incorrectly if:

- the actuator comes to a standstill before reaching the end position

- one of the red indication lights/LEDs is illuminated (torque fault)

-

the status indication S0007 in the display signals a fault.

3. If the end position setting is incorrect: Reset limit switching.

10.6.4. Reference operation position feedback: perform

For actuators with position feedback (RWG, potentiometer), a reference operation

has to be performed once the limit switching setting was changed to ensure that the

position feedback (0/4 – 20 mA) supplies correct values:

→

Operate actuator electrically (via the push buttons OPEN and CLOSE of the

local controls) once to end position OPEN and once to end position CLOSED.

10.7. Close switch compartment

✔

If options (e.g. potentiometer, position transmitter) are available: Only close switch

compartment once all optional equipment has been successfully set.

Corrosion due to damage to paint finish

→

Touch up damage to paint finish after work on the device.

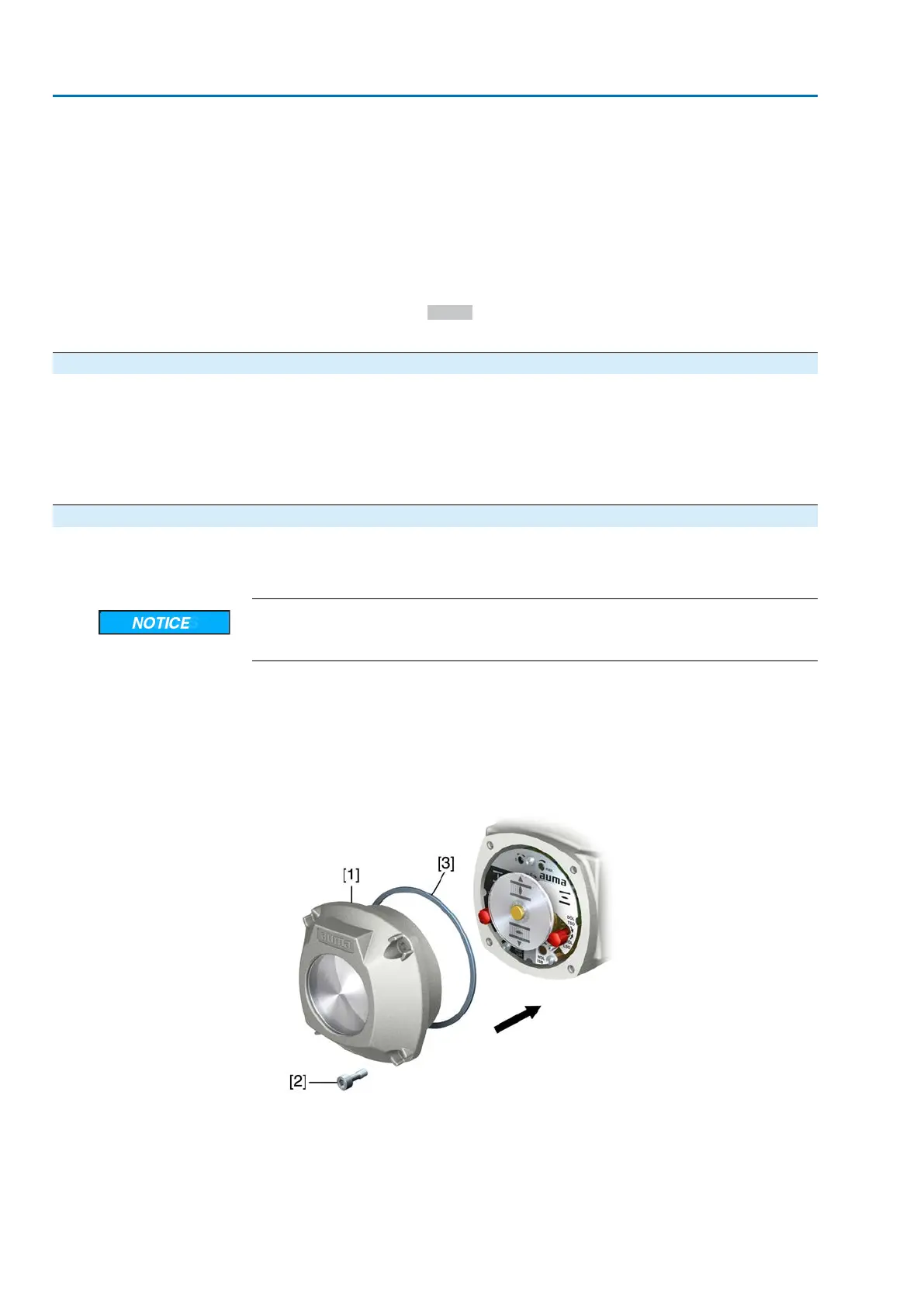

1. Clean sealing faces of housing and cover.

2. Preserve joint surfaces with an acid-free corrosion protection agent.

3. Check whether O-ring [3] is in good condition, replace if damaged.

4. Apply a thin film of non-acidic grease (e.g. petroleum jelly) to the O-ring and

insert it correctly.

Figure 69:

64

SAEx 07.2 – SAEx 16.2/SAREx 07.2 – SAREx 16.2 Control unit - electromechanical

Commissioning (basic settings) ACExC 01.2 Intrusive Profinet

Loading...

Loading...