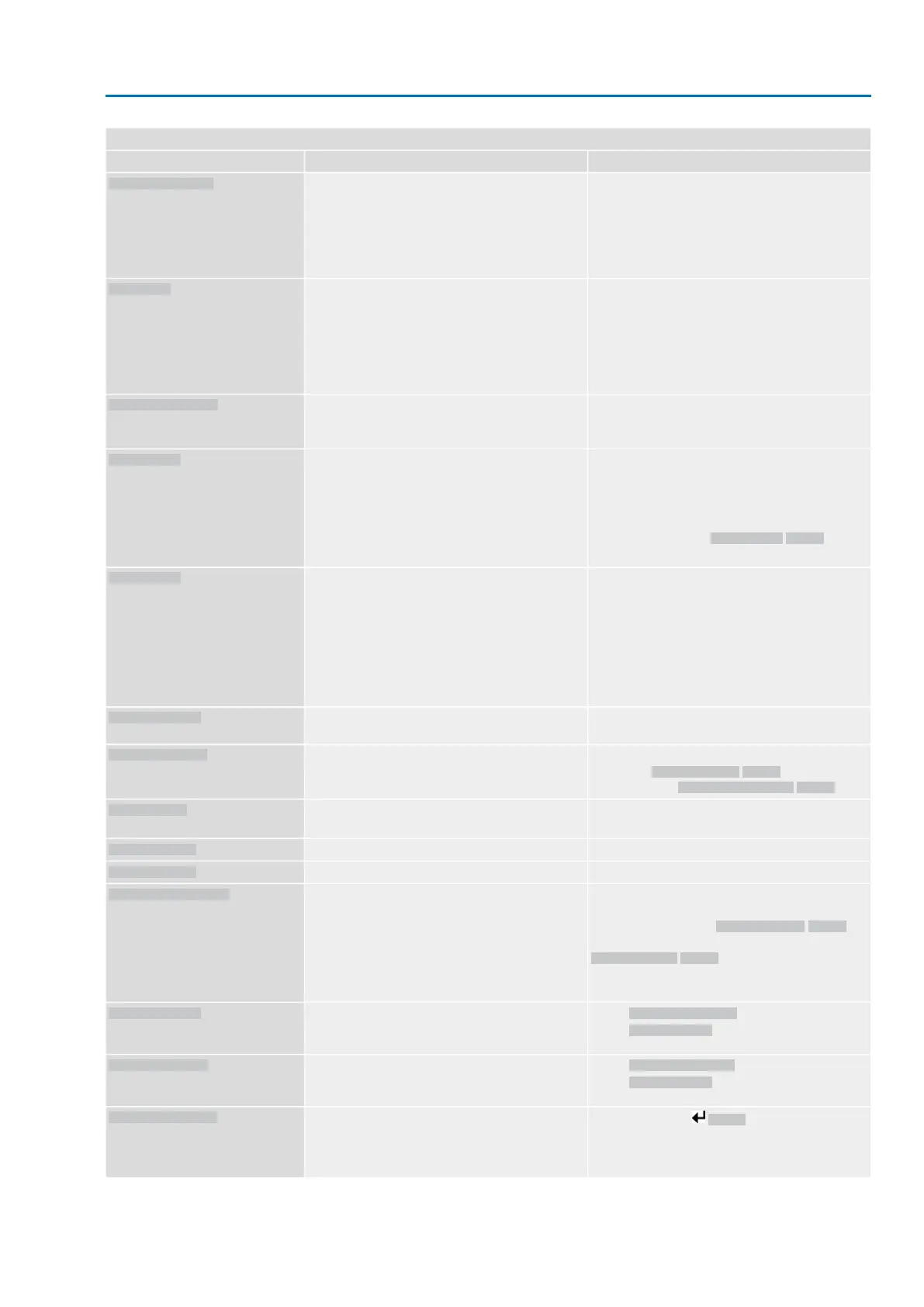

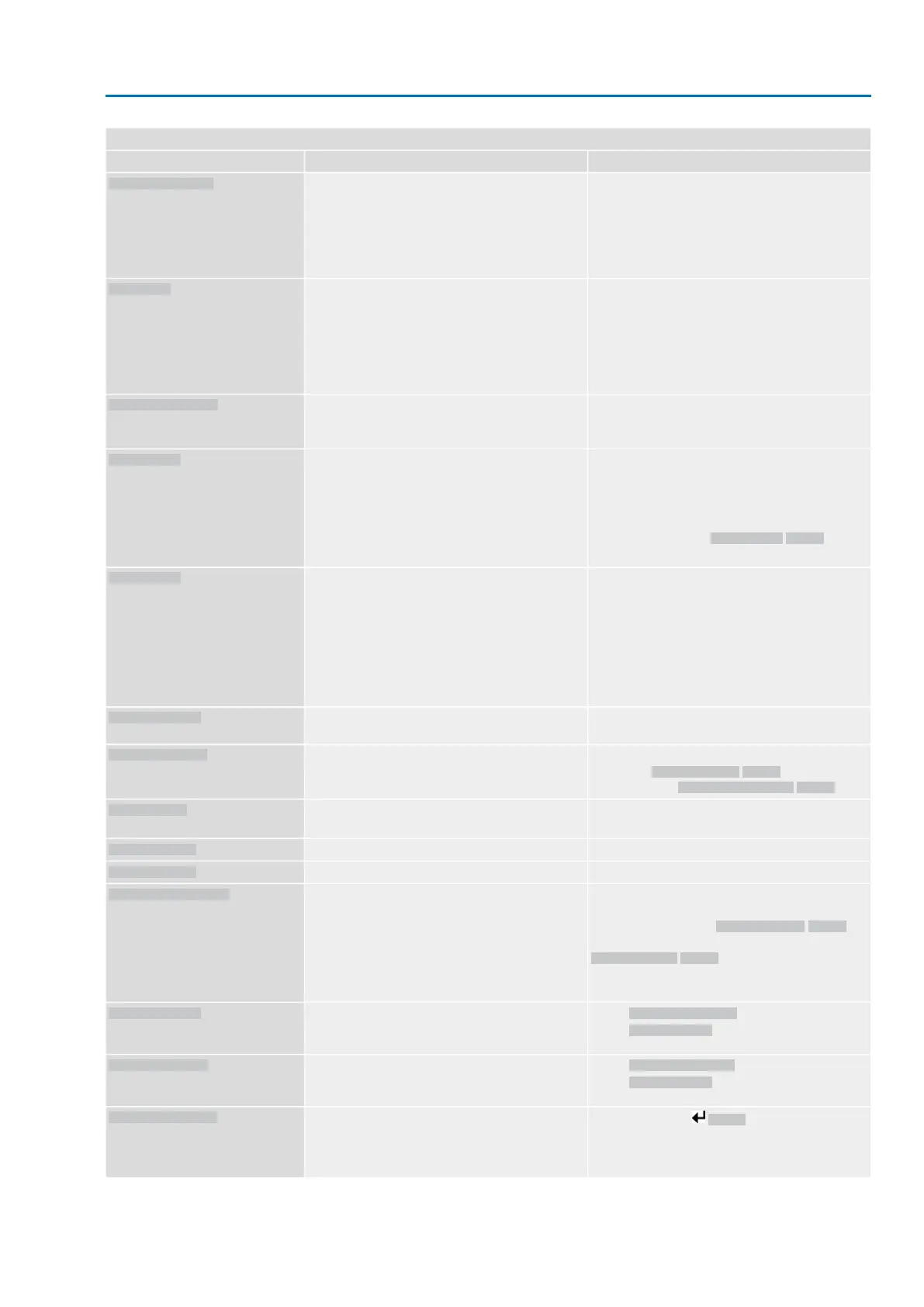

Faults and Failure

RemedyDescription/causeIndication on display

Perform one of the following measures:

●

Issue operation command in direction CLOSE.

●

Set selector switch to position Local control

(LOCAL) and reset fault indication via push

button RESET.

●

Execute reset command via fieldbus.

Torque fault in direction OPEN

Torque fault OPEN

Test/connect phases.

●

When connecting to a 3-ph AC system and with

internal 24 V DC supply of the electronics:

Phase 2 is missing.

●

When connecting to a 3-ph or 1-ph AC system

and with external 24 V DC supply of the elec-

tronics: One of the phases L1, L2 or L3 is

missing.

Phase fault

Correct the sequence of the phase conductors L1,

L2 and L3 by exchanging two phases.

The phase conductors L1, L2 and L3 are connected

in the wrong sequence.

Only applicable if connected to a 3-ph AC system.

Incorrect phase seq

●

Check mains voltage.

For 3-phase/1-phase AC current, the permiss-

ible variation of the mains voltage is ±10 %

(option ±30 %).The permissible variation of the

mains voltage is ±5 %

●

Check parameter Tripping time M0172, extend

time frame if required.

Due to insufficient mains quality, the controls cannot

detect the phase sequence (sequence of phase

conductors L1, L2 and L3) within the pre-set time

frame provided for monitoring.

Mains quality

●

Cool down, wait.

●

If the fault indication display persists after cool-

ing down:

-

Set selector switch to position Local con-

trol (LOCAL) and reset fault indication via

push button RESET.

-

Execute reset command via fieldbus.

●

Check fuses.

Motor protection tripped

Thermal fault

Check movement at actuator.No actuator reaction to operation commands within

the set reaction time.

Fault no reaction

Check device configuration:

Parameter Low limit Uspan M0832 must be less

than parameter Volt.level diff. potent. M0833.

Potentiometer is outside the permissible range.

Poti Out of Range

LPV: Lift Plug Valve function

The master actuator signals a fault

LPV not ready

1)

Check wiring.Loss of signal analogue input 1

Wrn input AIN 1

Check wiring.Loss of signal analogue input 2

Wrn input AIN 2

Check operation command control.

For 3-phase AC current mains, activate phase

monitoring (parameter Adapt rotary dir. M0171).

Check device configuration setting (parameter

Closing rotation M0176).

To delete the fault indication: Disconnect actuator

controls from the mains and perform reboot.

Contrary to the configured direction of rotation and

the active operation command, the motor turns into

the wrong direction.

Incorrect rotary direct.

Check DMF trip torque OP parameter.

Check DMF fault level parameter.

The torque in direction OPEN, measured at the

output drive shaft using the torque measurement

flange, is too high.

DMF fault OPEN

2)

Check DMF trip torque CL parameter.

Check DMF fault level parameter.

The torque in direction CLOSE, measured at the

output drive shaft using the torque measurement

flange, is too high.

DMF fault CLOSE

2)

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 25:

FQM collective fault

3)

For lift plug valve product variant1)

For actuators equipped with torque measurement flange (DMF)2)

75

SAEx 07.2 – SAEx 16.2/SAREx 07.2 – SAREx 16.2 Control unit - electromechanical

ACExC 01.2 Intrusive Profinet Corrective action

Loading...

Loading...