5.3.2 Cable connection

Table 6: Terminal cross sections and tightening torques

Tightening torquesTerminal cross sectionsType

1.5 – 1.8 Nmmax. 10 mm² (flexible or solid)Power terminals (U, V, W)

3.0 – 4.0 Nmmax. 10 mm² (flexible or solid)PE connection

0.6 – 0.8 Nmmax.2.5 mm² (flexible or solid)Control contacts (1 to 50)

1. Strip wires.

2. For flexible cables: Use end sleeves according to DIN 46228.

3. Connect cables according to order-related wiring diagram.

In case of a fault: Hazardous voltage while protective earth conductor is NOT

connected!

Risk of electric shock.

→

Connect all protective earth conductors.

→

Connect PE connection to external protective earth conductor of connecting

cables.

→

Start running the device only after having connected the protective earth con-

ductor.

4. Tighten protective earth firmly to PE connection

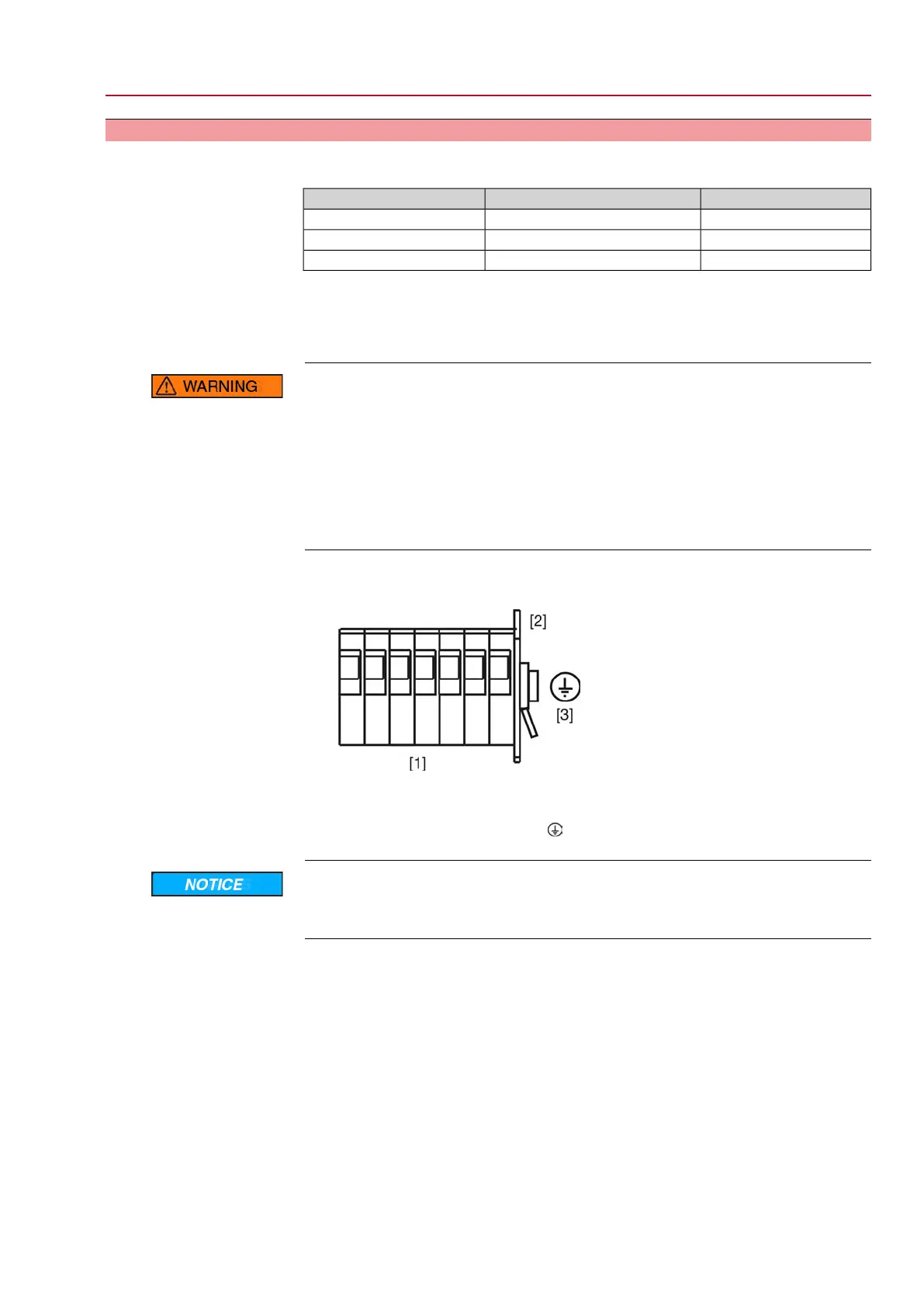

Figure 19: PE connection

[1] Terminal blocks

[2] Terminal housing

[3]

PE connection, symbol:

Danger of corrosion: Damage due to condensation!

→

After mounting, commission the device immediately to ensure that heater mini-

mises condensation.

Information Some actuators are equipped with an additional motor heater. The motor heater

minimises condensation within the motor and improves the start-up behaviour for

extremely low temperatures.

23

SGExC 05.1 – SGExC 12.1 Control unit: electromechanic

ACExC 01.2 Intrusive Modbus RTU Electrical connection

Loading...

Loading...