2. Turn torque dial [4] to set the required torque (1 da Nm = 10 Nm). Example:

-

Black torque switching head set to approx. 25 da Nm ≙ 250 Nm for direction

CLOSE

-

White torque switching head set to approx. 20 da Nm ≙ 200 Nm for direction

OPEN

3. Fasten lock screws [3] again.

Information: Maximum tightening torque: 0.3 – 0.4 Nm

➥

The torque switch setting is complete.

9.5. Limit switching: set

The limit switching records the travel. When reaching the preset position, switches

are operated.

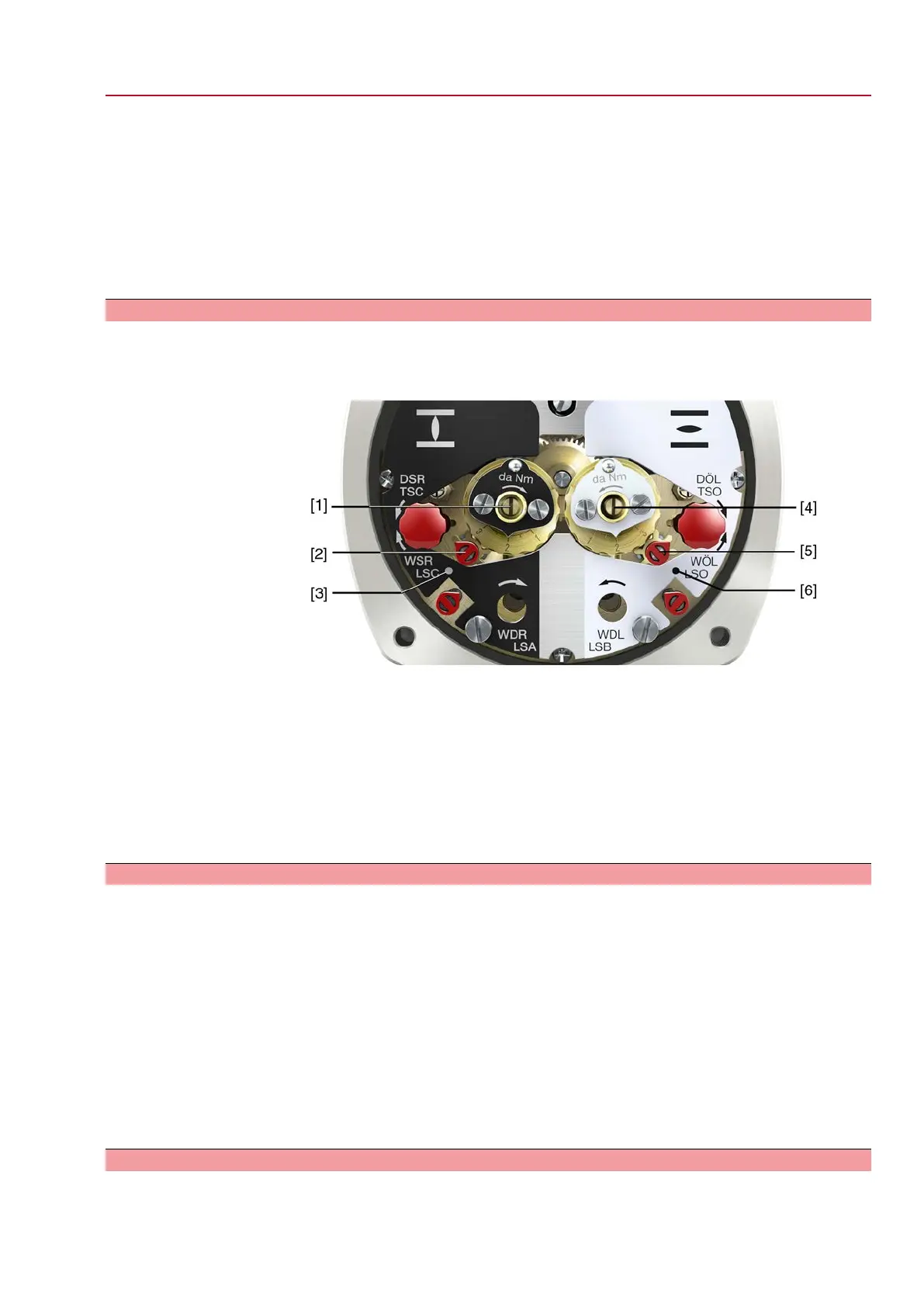

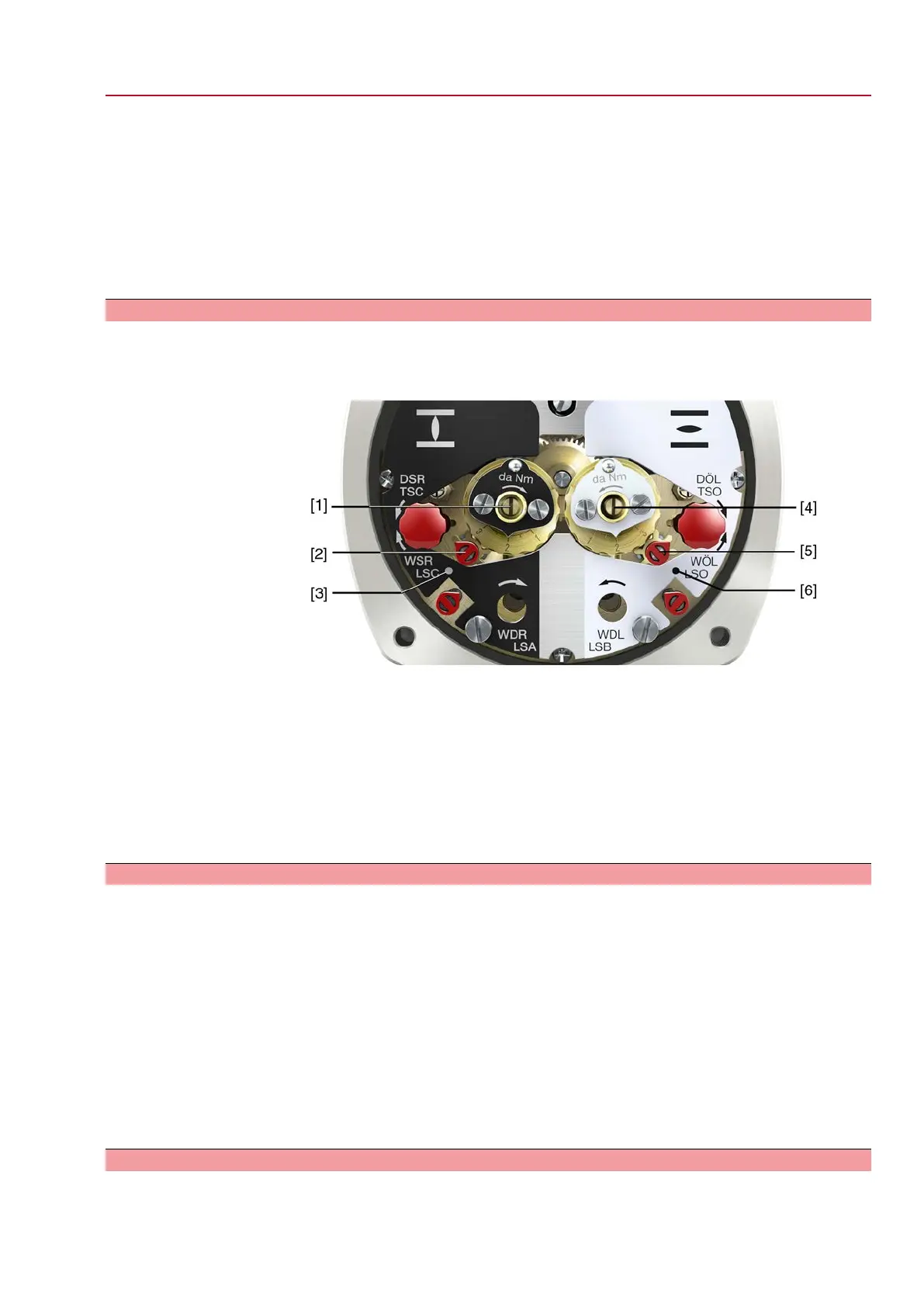

Figure 68: Setting elements for limit switching

Black section:

[1] Setting spindle: End position CLOSED

[2] Pointer: End position CLOSED

[3] Mark: End position CLOSED is set

White section:

[4] Setting spindle: End position OPEN

[5] Pointer: End position OPEN

[6] Mark: End position OPEN is set

9.5.1. End position CLOSED (black section): set

1. Engage manual operation.

2. Turn handwheel clockwise until valve is closed.

3. Press down and turn setting spindle [1] with screw driver in direction of the

arrow and observe the pointer [2]: While a ratchet click is felt and heard, the

pointer [2] moves 90° every time.

4. As soon as the pointer [2] is 90° from mark [3]: Continue turning slowly.

5. As soon as the pointer [2] moves to mark [3]: Stop turning and release setting

spindle.

➥

The end position CLOSED setting is complete.

6. If you override the tripping point inadvertently (ratchet click is heard after the

pointer has snapped): Continue turning the setting spindle in the same direction

and repeat setting process.

9.5.2. End position OPEN (white section): set

1. Engage manual operation.

2. Turn handwheel counterclockwise until valve is open.

61

SQEx 05.2 – SQEx 14.2 / SQREx 05.2 – SQREx 14.2 Control unit - electromechanical

ACExC 01.2 Intrusive Commissioning (basic settings)

Loading...

Loading...