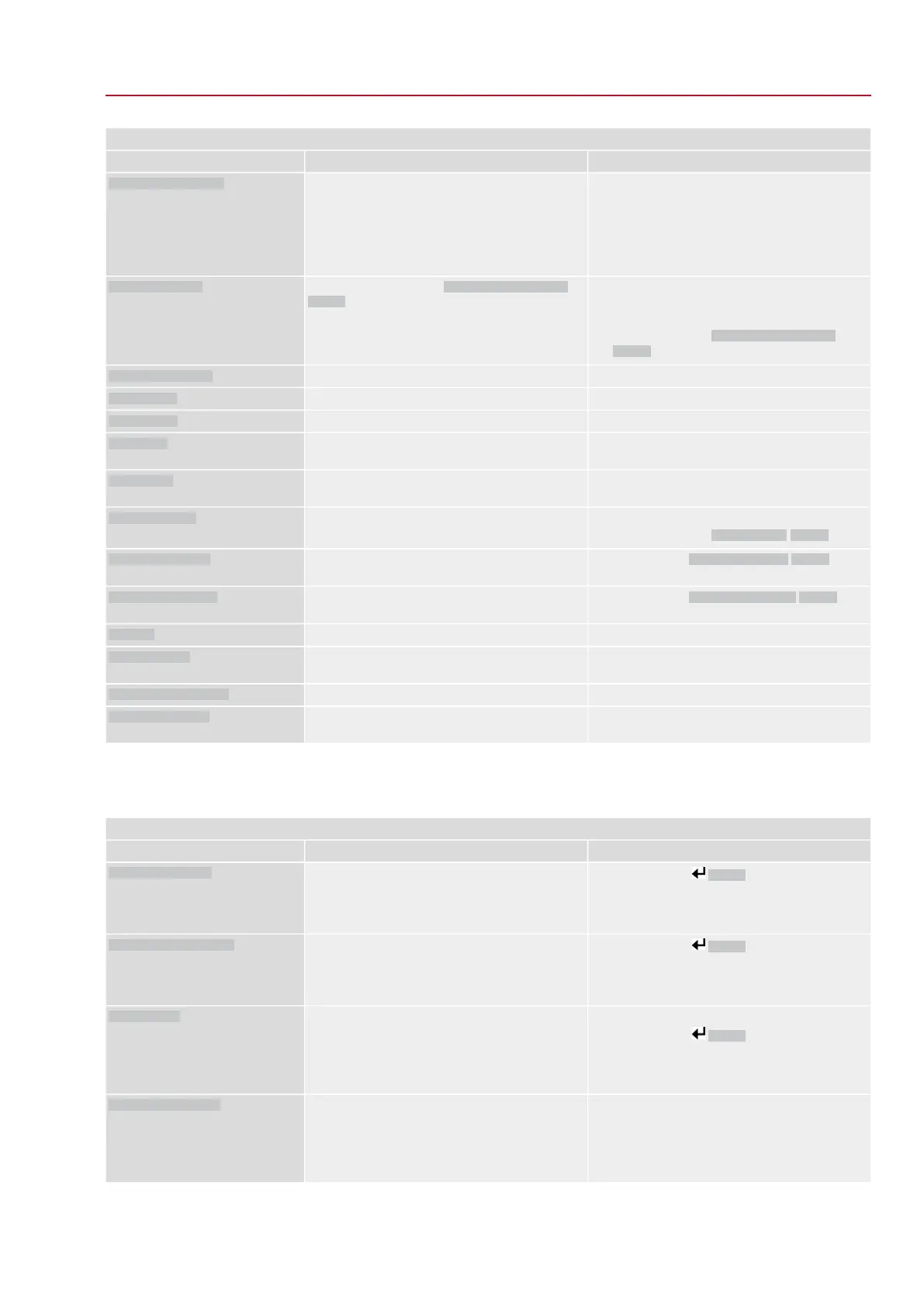

Warnings and Out of specification

RemedyDescription/causeIndication on display

Check setpoint signal.Warning: Loss of signal setpoint position

Possible causes:

For an adjusted setpoint range of e.g. 4 – 20 mA,

the input signal is 0 (signal loss).

For a setpoint range of 0 – 20 mA , monitoring is

not possible.

Wrn setpoint position

The warning indications are automatically cleared

once a new operation command is executed.

●

Check valve.

●

Check parameter Perm.op. time, manual

M0570.

The set time (parameter Perm.op. time, manual

M0570) has been exceeded.The preset operating

time is exceeded for a complete travel from end

position OPEN to end position CLOSED.

Op. time warning

Measure/reduce ambient temperature.Temperature within controls housing too high.

Wrn controls temp.

Set time.Real time clock has not yet been set.

Time not set

Replace button cell.Voltage of the RTC button cell is too low.

RTC voltage

Check actuator (PVST settings).Partial Valve Stroke Test (PVST) could not be suc-

cessfully completed.

PVST fault

Perform RESET or restart PVST.Partial Valve Stroke Test (PVST) was aborted or

could not be started.

PVST abort

●

Check movement at actuator.

●

Check parameter Reaction time M0634.

No actuator reaction to operation commands within

the set reaction time.

Wrn no reaction

Check parameter Wrn torque OPEN M0768, re-set

if required.

Limit value for torque warning in direction OPEN

exceeded.

Torque wrn OPEN

Check parameter Wrn torque CLOSE M0769, re-

set if required.

Limit value for torque warning in direction CLOSE

exceeded.

Torque wrn CLOSE

Refer to separate Manual Functional Safety.SIL sub-assembly fault has occurred.

SIL fault

1)

Execution of PVST (Partial Valve Stroke Tests) is

required.

PVST required

Maintenance is required.

Maintenance required

Checking and fault remedy are required. Refer to

FQM operation instructions.

FQM fault

FQM fail safe fault

2)

For actuators controls in SIL version1)

For actuators with fail safe unit2)

Table 29:

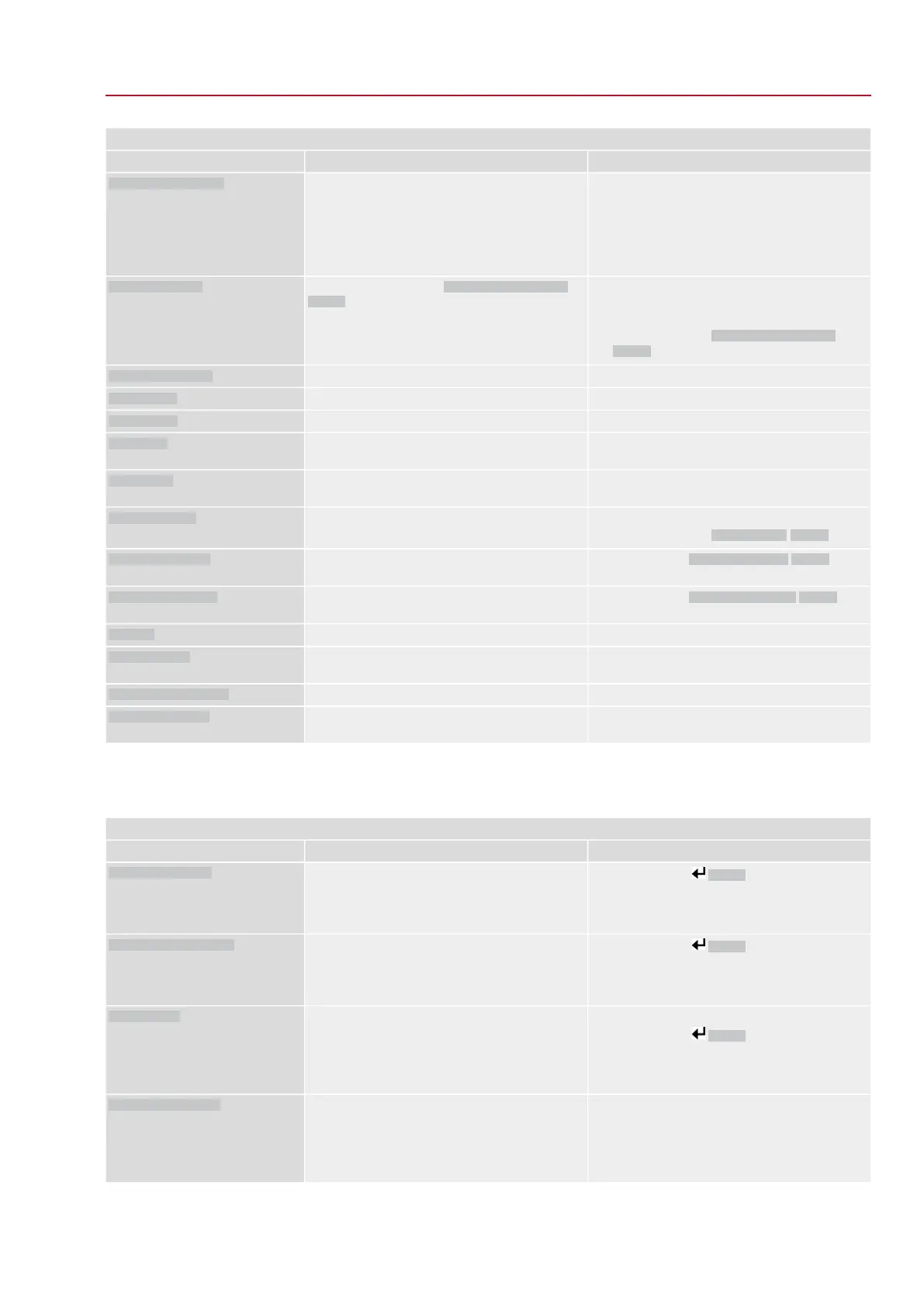

Faults and Failure

RemedyDescription/causeIndication on display

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 11:

Configuration error has occurred.

Configuration error

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 22:

Configuration error has occurred.

Config. error REMOTE

AUMA service

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 14:

Internal error has occurred.

Internal error

Perform one of the following measures:

●

Issue operation command in direction OPEN.

●

Set selector switch to position Local control

(LOCAL) and reset fault indication via push

button RESET.

Torque fault in direction CLOSE

Torque fault CLOSE

73

SQEx 05.2 – SQEx 14.2 / SQREx 05.2 – SQREx 14.2 Control unit - electromechanical

ACExC 01.2 Intrusive Corrective action

Loading...

Loading...