Instructions, AutroFlame X33AF, 116-P-X33AF/IGB, rev. E, 2013-08-13, P/N 95-8625-17.1, Rev: 2/13

Autronica Fire and Security AS

Page 2

The Auxiliary relay has normally open / normally closed

contacts, and is congurable for energized or de-energized

operation, and latching or non-latching operation.

0 to 20 mA Output

A 0 to 20 mA output is available as an option (in addition

to the three relays). This option provides a 0 to 20 mA dc

current output for transmitting detector status information

to other devices. The circuit can be wired in either an

isolated or non-isolated conguration and can drive a

maximum loop resistance of 500 ohms from 18 to 19.9

Vdc and 600 ohms from 20 to 30 Vdc. Table 1 indicates

the detector status conditions represented by the various

current levels. The output is calibrated at the factory, with

no need for eld calibration. A model with relays and

0-20 mA with HART is also available. Refer to Addendum

number 116-P-X33AFADDENDUM/YGB for complete

details.

NOTE

The output of the 0 to 20 mA current loop is not

monitored by the fault detection circuitry of the

X33AF. Therefore, an open circuit on the loop will

not cause the fault relay to change state or the

detector status LED to indicate a fault. The status of

the LED always follows the status of the relays.

An alarm condition will normally over-ride a fault condition,

unless the nature of the fault condition impairs the ability

of the detector to generate or maintain an alarm output,

i.e. loss of operating power.

LED

A tricolor LED on the detector faceplate indicates normal,

re alarm and fault conditions. Table 2 indicates the

condition of the LED for each status.

Table 2—Detector Status Indicator

OPICAL INTEGRITY (

o

i

)

Automatic

o

i

The X33AF includes the Automatic Optical Integrity

(

o

i

) feature — a calibrated performance test that is

automatically performed once per minute to verify

complete detector operation capabilities. No testing with an

external test lamp is required. The detector automatically

performs the same test that a maintenance person with a

test lamp would perform — once every minute, 60 times

per hour. However, a successful Automatic

o

i

test does

not produce an alarm condition.

The Protect•IR signals a fault condition when less than

half of the detection range remains. This is indicated by

the Fault output relay and is evident by the yellow color of

the LED on the face of the detector. The

o

i

fault condition

is self-clearing if the optical contamination is temporary. If

the contamination is not automatically cleared and the

o

i

fault remains, the detector may require cleaning or service.

See the "Troubleshooting" section for further information.

Magnetic

o

i

/ Manual

o

i

The detector also incorporates both Magnetic

o

i

(Mag

o

i

) and Manual

o

i

(Man

o

i

) features that provide the

same calibrated test as the Automatic

o

i

, and in addition

actuates the Alarm output to verify operation for preventive

maintenance requirements. These features can be

performed at any time and eliminate the need for testing

with a non-calibrated external test lamp.

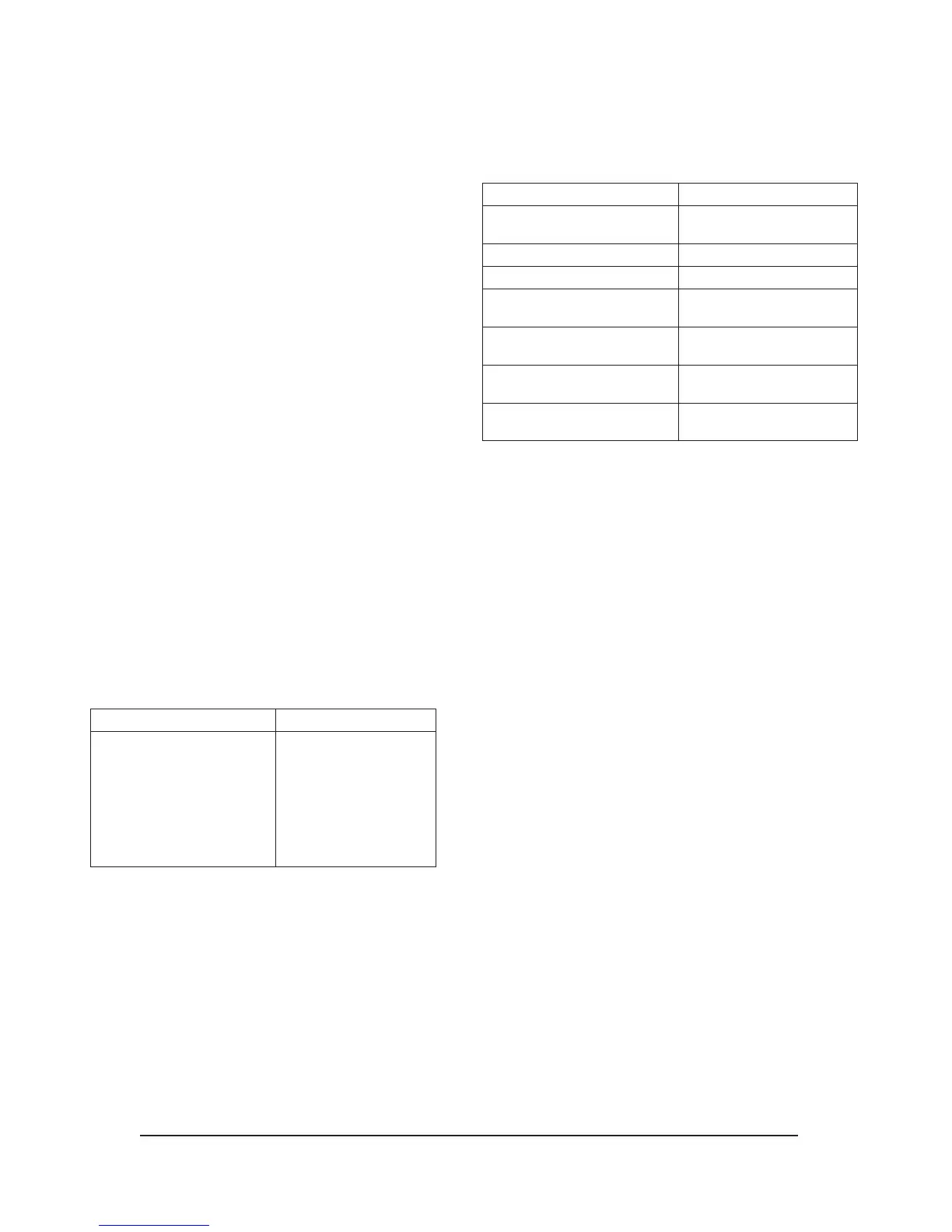

Table 1—Detector Status Conditions Indicated by Current Level

Current Level (±0.3 mA) Detector Status

0 mA Power Fault

1 mA General Fault

2 mA Oi Fault

3 mA Hi Background IR Fault

4 mA Normal Operation

20 mA Fire Alarm

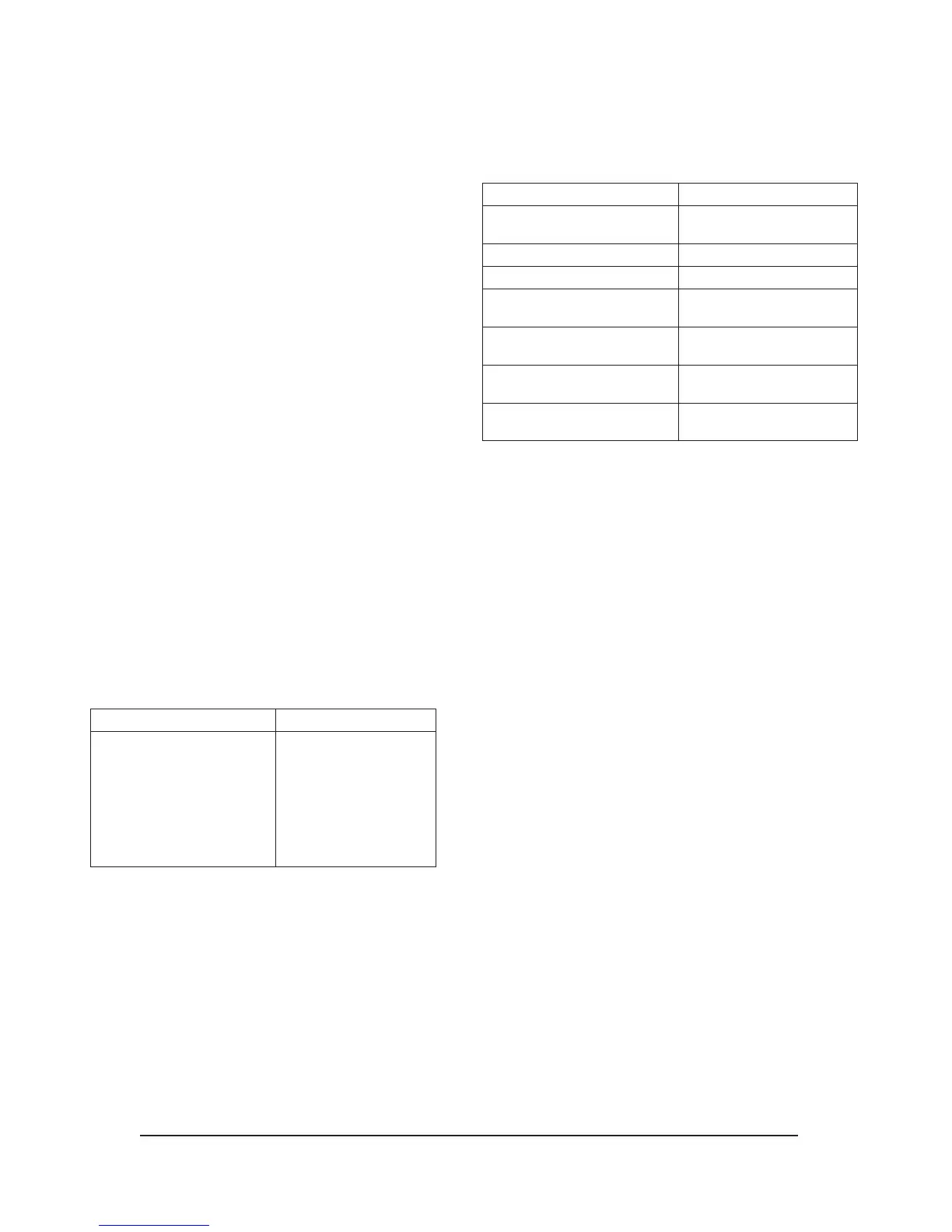

Detector Status LED Indicator

Power On/Normal Operation

(no fault or re alarm)

Green

Fault Yellow

Fire (Alarm) Red

Low Sensitivity

One Yellow Flash

During Power-up

T- Low Sensitivity

Three Yellow Flashes

During Power-up

Medium Sensitivity

Two Yellow Flashes

During Power-up

Very High Sensitivity

Four Yellow Flashes

During Power-up

NOTE: See "Detector Sensitivity Levels" for additional information.

Loading...

Loading...