Instructions, AutroFlame X33AF, 116-P-X33AF/IGB, rev. E, 2013-08-13, P/N 95-8625-17.1, Rev: 2/13

Autronica Fire and Security AS

Page A-1

APPENDIX A – FM APPROVAL AND PERFORMANCE REPORT

THE FOLLOWING ITEMS, FUNCTIONS AND OPTIONS DESCRIBE THE FM APPROVAL:

• Explosion-proof for Class I, Div. 1, Groups B, C and D (T4A) Hazardous (Classied) Locations per FM 3615.

• Dust-ignition proof for Class II/III, Div. 1, Groups E, F and G (T4A) Hazardous (Classied) Locations per FM 3615.

• Nonincendive for Class I, Div. 2, Groups A, B, C and D (T3C) Hazardous (Classied) Locations per FM 3611.

• Nonincendive for Class II, Div. 2, Groups F and G (T3C) Hazardous (Classied) Locations per FM 3611.

• Enclosure rating NEMA/Type 4X per NEMA 250.

• Ambient Temperature Limits: –40°F to +167°F (–40°C to +75°C).

• Automatic Fire Alarm Signaling Performance veried per FM 3260 (2000).

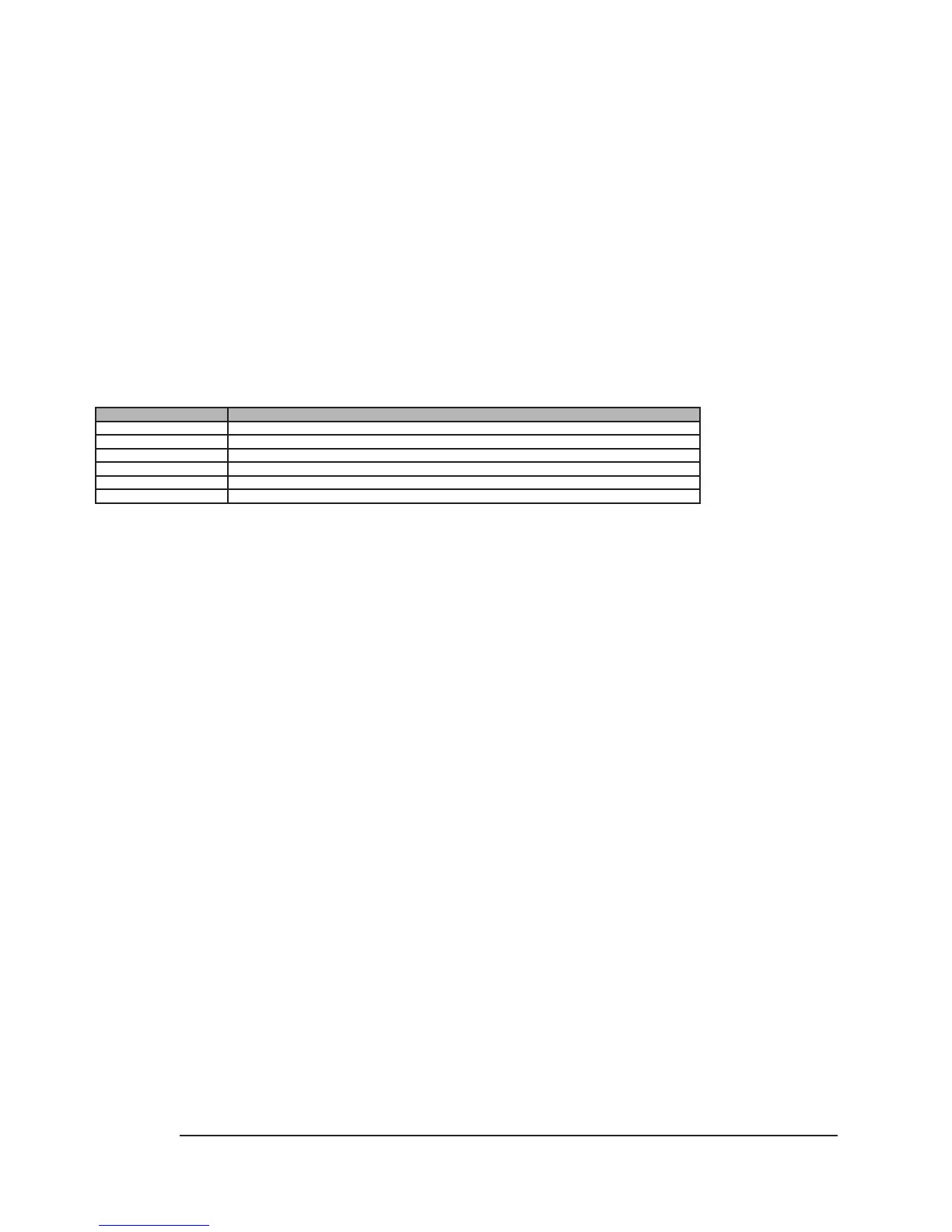

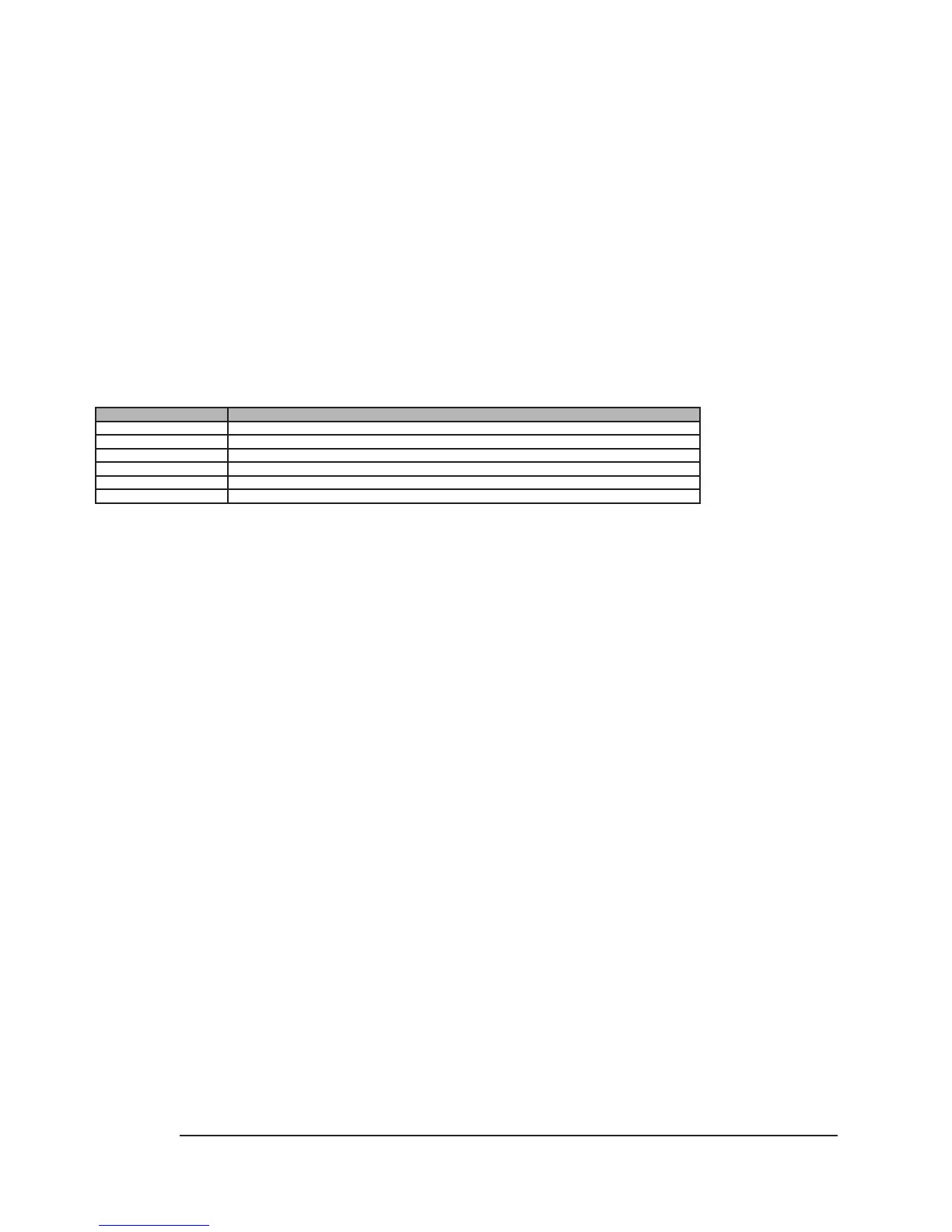

The following accessories are FM approved for use with the X33AF Flame Detector:

Part Number Description

116-102740-002 Magnet

116-007739-001 Magnet and Extension Pole

116-010857-001 Q1130A1001 Flange Mount Assembly

116-007290-001 Q9033B Stainless Steel Mounting Arm Assembly is for aluminum and stainless steel detectors

116-007290-002 Q9033A Aluminum Mounting Arm Assembly is for aluminum detectors only

116-011385-001 Q9033 Collar Attachment

The following performance criteria were veried:

AUTOMATIC OPTICAL INTEGRITY TEST:

The detector generated an optical fault in the presence of contamination on any single or combination of lens surfaces

resulting in a loss of approximately 50% of its detection range, verifying that the detector performs a calibrated Automatic

Optical Integrity (

o

i

) test for each sensor. Upon removal of the contamination, the detector fault was cleared and the

detector was veried to detect a re.

MANUAL OPTICAL INTEGRITY TEST:

The Manual / Magnetic

o

i

performs the same calibrated test as the Automatic

o

i

, and additionally actuates the alarm

relay to verify output operation. If there is a 50% loss of its detection range, an alarm signal is not generated.

The Optical Integrity test procedure, as described in the "Magnetic

o

i

/ Manual

o

i

"

section of this instruction manual, is

the approved external optical test method for this detector to verify end-to-end detector function. This test replaces the

function and need of a traditional external test lamp.

Loading...

Loading...