32 USER MANUAL

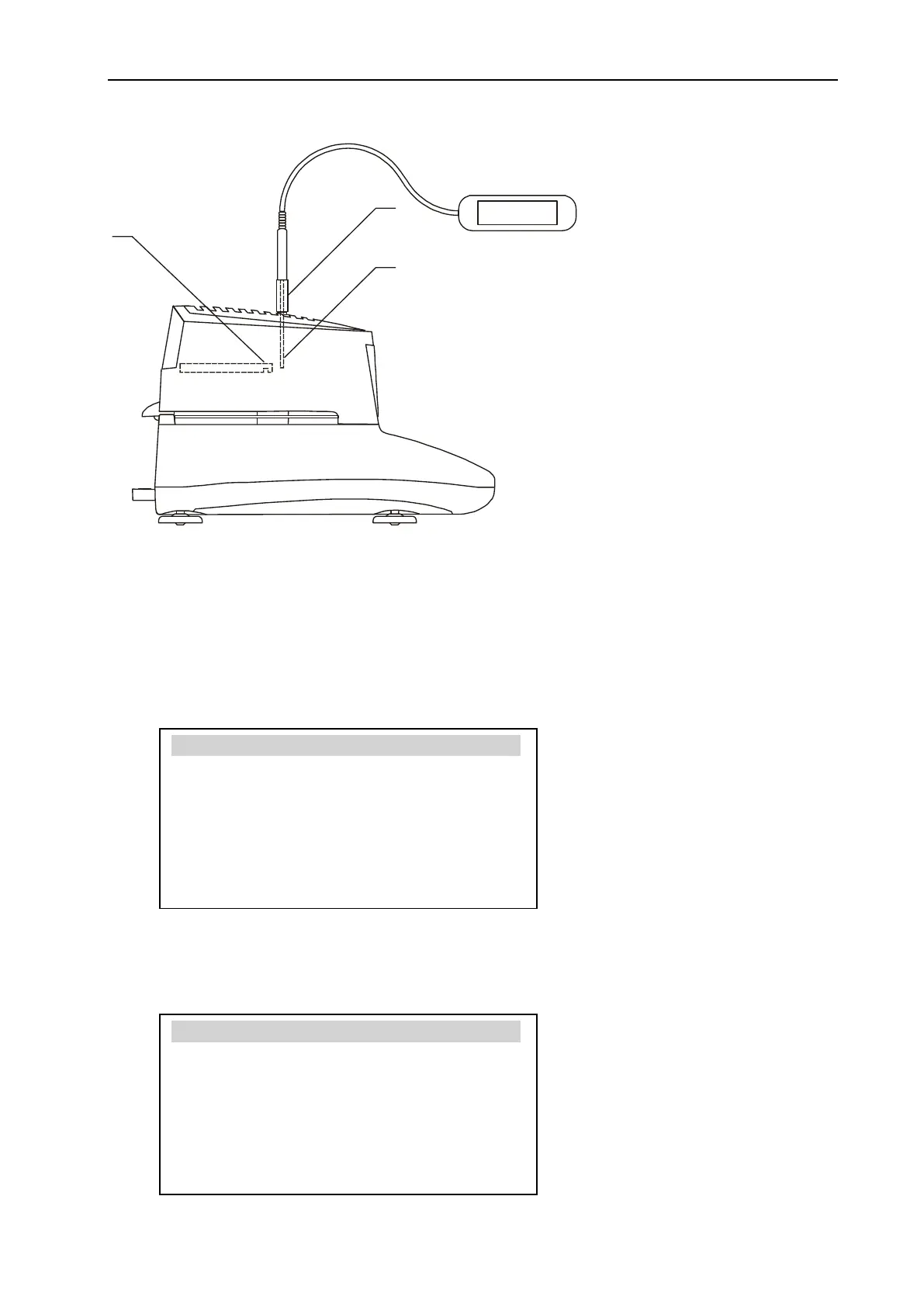

The way of entering control thermometer probe to moisture analyzer drying chamber:

1 – control thermometer probe

2 – distance sleeves 2x20mm

(2 sleeves ensure that position of

control thermometer probe is the

same as moisture analyzer internal

temperature sensor, 1 sleeve – on the

upper edge of the single-use pan)

3 – moisture analyzer internal sensor

Before executing temperature correction (inscribing T1 and T2 temperature) drying

cycle must be made with inscribed T1 temperature and drying time 15 minutes. It is

suggested to put the material sample on the pan. At the end of drying process write

down moisture analyzer temperature indication ( T value on the left side of moisture

analyzer display) and control thermometer indication.

Both indications are needed for correction:

Subsequently make drying cycle for T2 temperature (drying time as above 15 minutes)

and write down indications again.

This way both T2 indications are inscribed:

TEMP. CORRECTION

1. Moisture temp. T1 =

2. Control temp. T1=

3. Moisture temp. T2 =

4. Control temp. T2=

5. Status <ON>

6. Exit

TEMP. CORRECTION

1. Moisture temp. T1 =

2. Control temp. T1=

3. Moisture temp. T2 =

4. Control temp. T2=

5. Status <ON>

6. Exit

Loading...

Loading...