3-3

Chapter 3: Operation

3.1.1 Overview of auto-setup

Use this procedure to automatically set the following items.

(1) Zero/span adjustment

(However, by default the span point is set so that the overstroke becomes 10%. If

a span adjustment is done after auto-setup, the device changes and saves the over-

stroke setting.)

(2) Configuration of actuator operation

(3) Configuration of the LRV (lower range value, the input signal at 0%) and URV

(upper range value, the input signal at 100%) of the input signal

• If actuator operation is reverse operation: LRV = 4 mA, URV = 20 mA

• If actuator operation is direct operation: LRV = 20 mA, URV = 4 mA

(4) Configuration of actuator size (Param)

(5) Configuration of hysteresis difference (Hys)

(Set the gland packing hysteresis difference from among three types: LIGHT, ME-

DIUM, and HEAVY.)

(6) Travel transmission fail-safe setting

Warning

•

During auto-setup the valve moves from fully closed to fully open. Take appropriate

measures beforehand to ensure that the movement of the valve will not cause injury

or have an effect on the process.

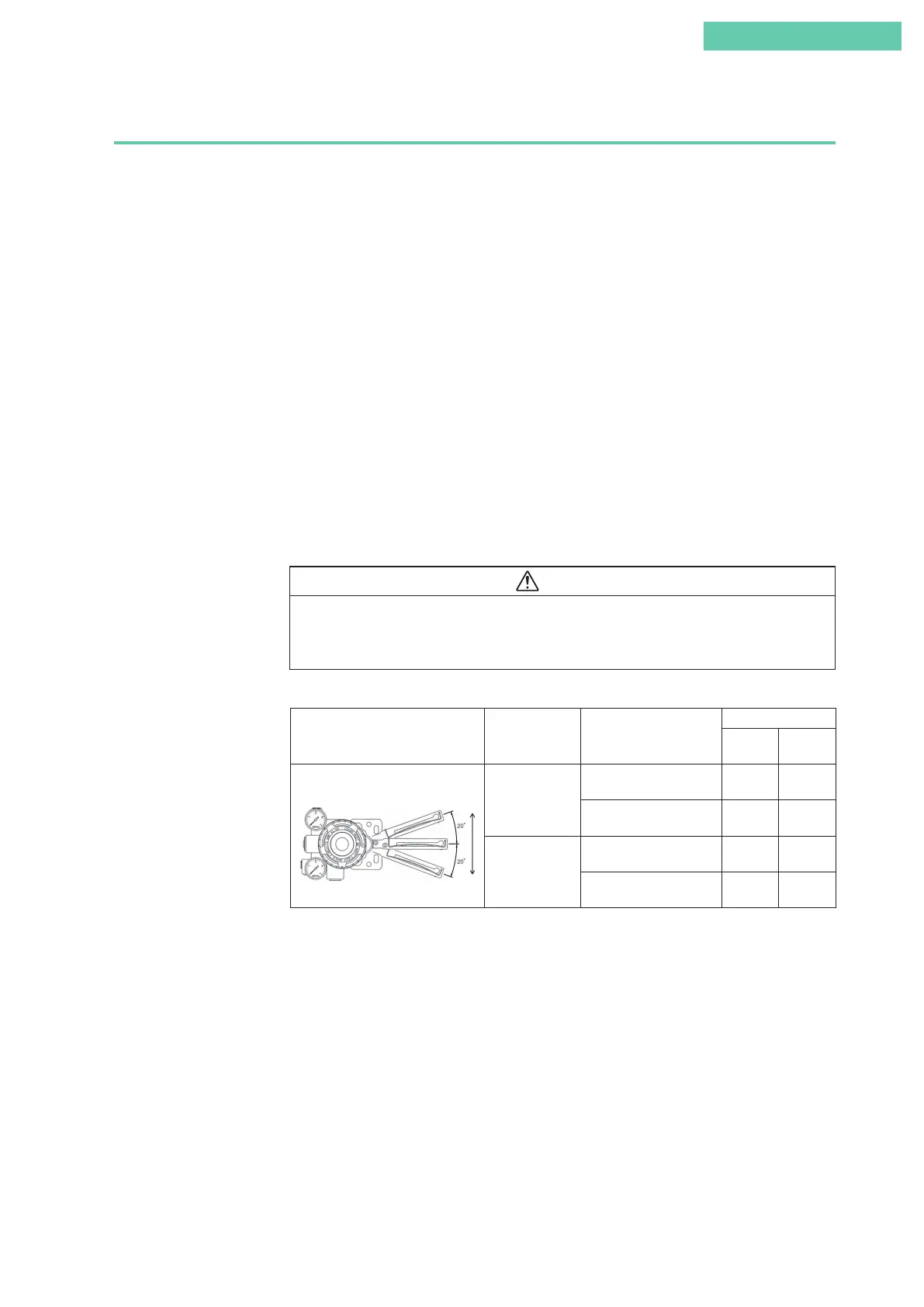

Table 3-1. Integral type setting

Lever Movement Valve Direction Valve Control Action

Setting

Actuator

Action

Valve

Action

Up → Down

Closed → Open

Direct (Closed: 20 mA;

open: 4 mA)

Reverse Reverse

Reverse (Closed: 4 mA;

open: 20 mA)

Direct Reverse

Open → Closed

Direct (Closed: 20 mA;

open: 4 mA)

Direct Direct

Reverse (Closed: 4 mA;

open: 20 mA)

Reverse Direct

If the valve action parameters to which the device is configured using Tables 3-1 and 3-2

are the reverse close (REVERSE) values, see 4.4.3, “Valve system,” in this document, and

set valve action to the reverse close settings.

If the valve action parameters to which the device is configured using Tables 3-1 and

3-2 are the direct close (DIRECT) values, no parameter configuration is required. (The

device is shipped from the factory set to “direct close (DIRECT).”)

Up

Down

Loading...

Loading...