2-4

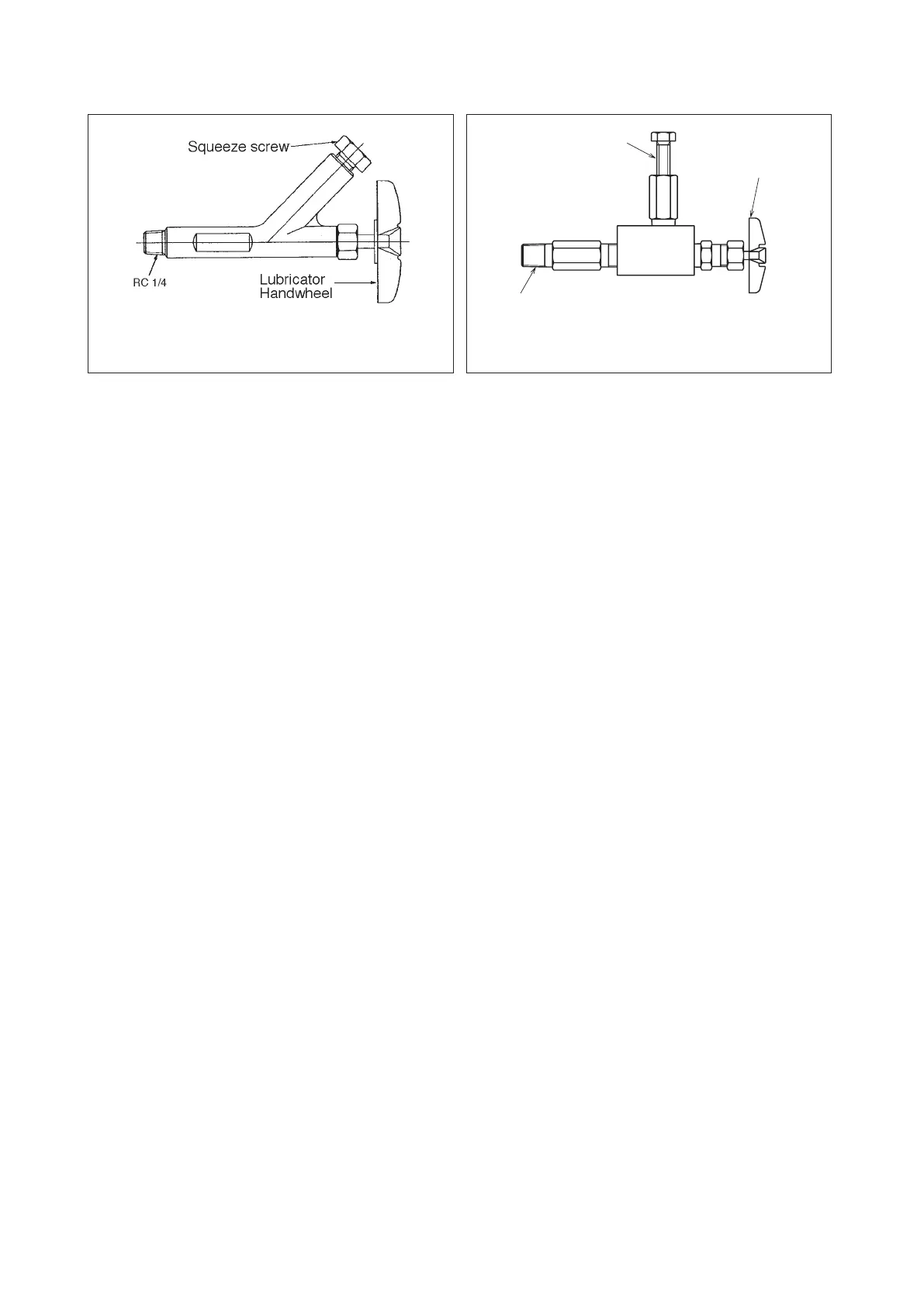

Squeeze

Screw

Lubricator

Figure 2-2 Lubricator (Class 600 or under)

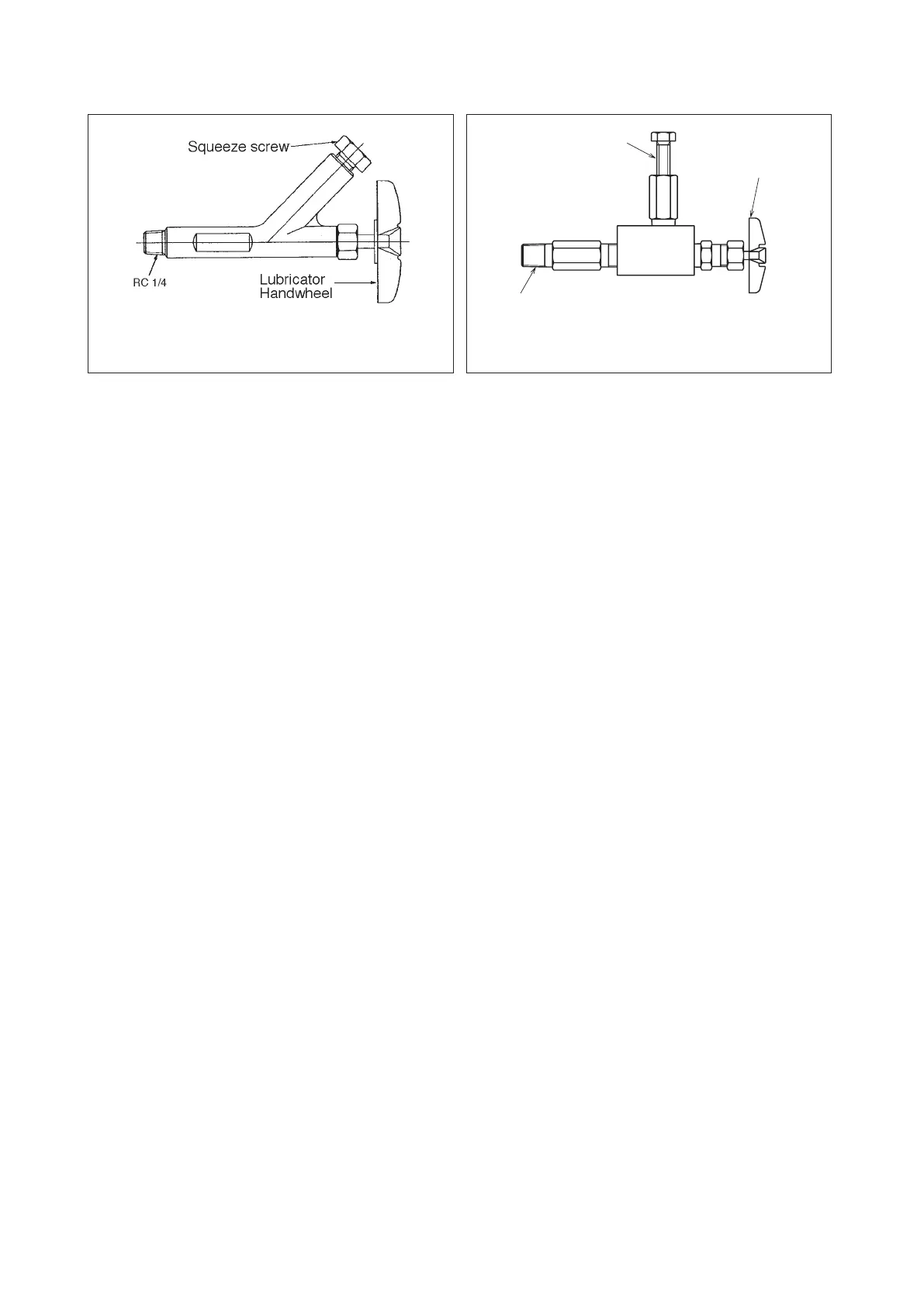

Figure 2-3 Lubricator for High Pressure Valve

(Class 600 or higher)

Lubricating procedure

(a) prepare grease of the type indicated on the nameplate.

(b) Tightly close the lubricator handwheel.

(c) Remove the squeeze screw, apply grease, and set the squeeze screw.

(d) Loosen the lubricator handwheel and drive grease by turning the squeeze screw.

(e) Repeat the procedure of 0), (c) and (d) until turning of the squeeze screw becomes

heavier. Tightly close lubricator handwheel.

(5) Pressurizing valve, check that there is no leak from the gasket sections for connection

to the valve body and process pipe. If leak is found, tighten the nuts. (Especially when

the process fluid temperature is 400 or higher, tighten the nuts again after raising

temperature of the valve in order that it may serve for a longer period without requiring

immediate maintenance service.) Standard tightening torques are shown in Table 4-4,

Table 4-5 of Chapter 4.

(6) When raising temperature of a valve which is used for high temperature service, raise

temperature gradually (standard rate is 100 per hour) and do not operate the valve when

its temperature is being raised.

Loading...

Loading...