4-29

Disassembly of actuator

<Disassembly procedure>

Disassembly procedure of actuator is described herein. Refer to Figure 4-26 and Figure 4-27 or

Table 4-4 for the information.

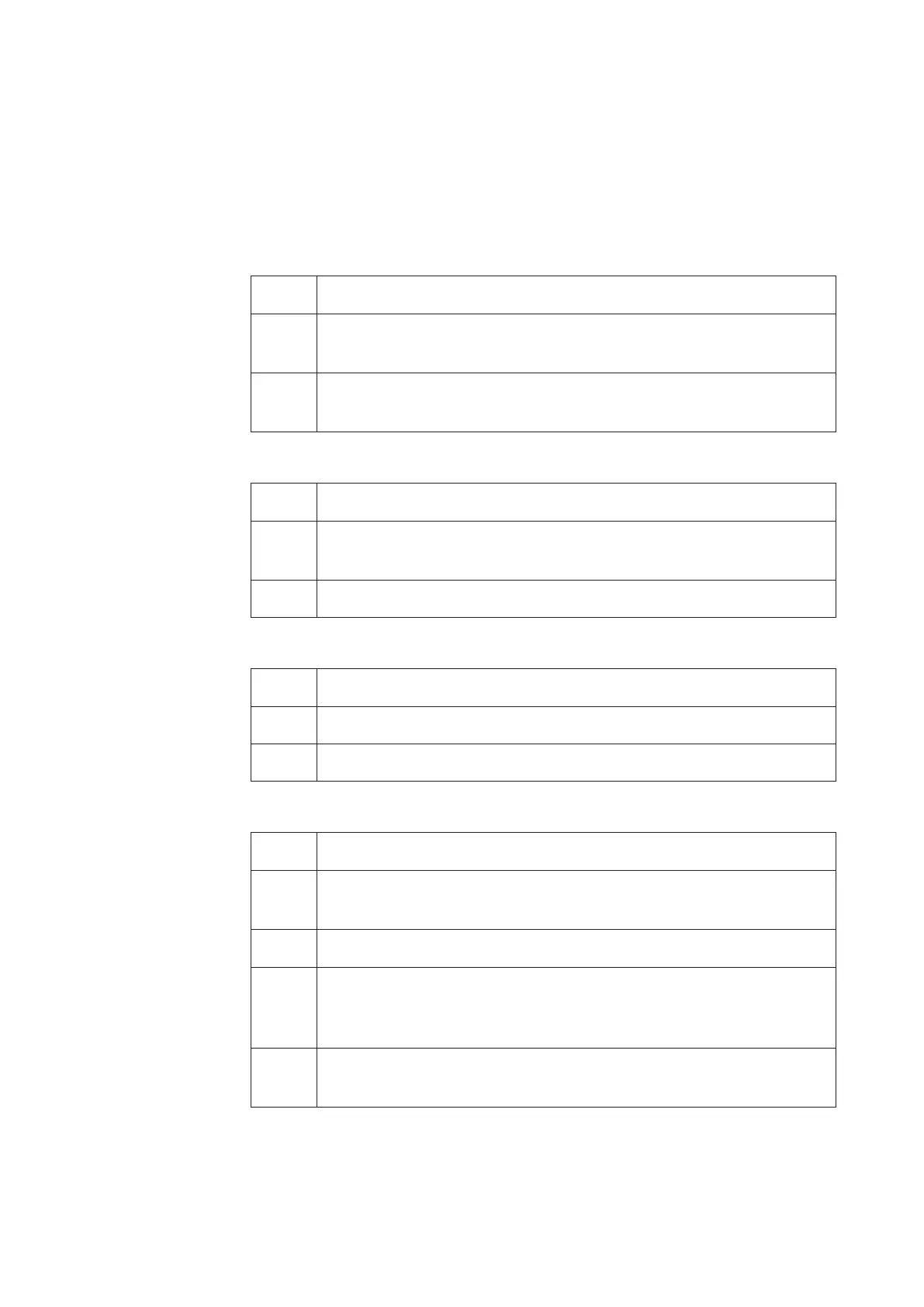

1. Marking and protection

Step Procedure

1 Match the mark of the spring retainer No.10 at the top of actuator, lift stopper

No.13, cylinder No.14 and cylinder assembling yoke boss.

2 Wrap PVC tape around thread part of rod to protect sealing parts, and the guide

bushing.

2. Removing slide screw rotation stopper (In case of with handwheel)

Step Procedure

1 Loosen hex head bolt No.37 and hex nuts Mo.38 which fasten the slide screw

rotation stopper No.36.

2 Remove slide screw rotation stopper No.36.

3. Removing spring retainer

Step Procedure

1 Loosen hex nuts No.2 and eye nut No.1 at the top of actuator and remove.

2 Lift spring retainer No.10 straight up and remove.

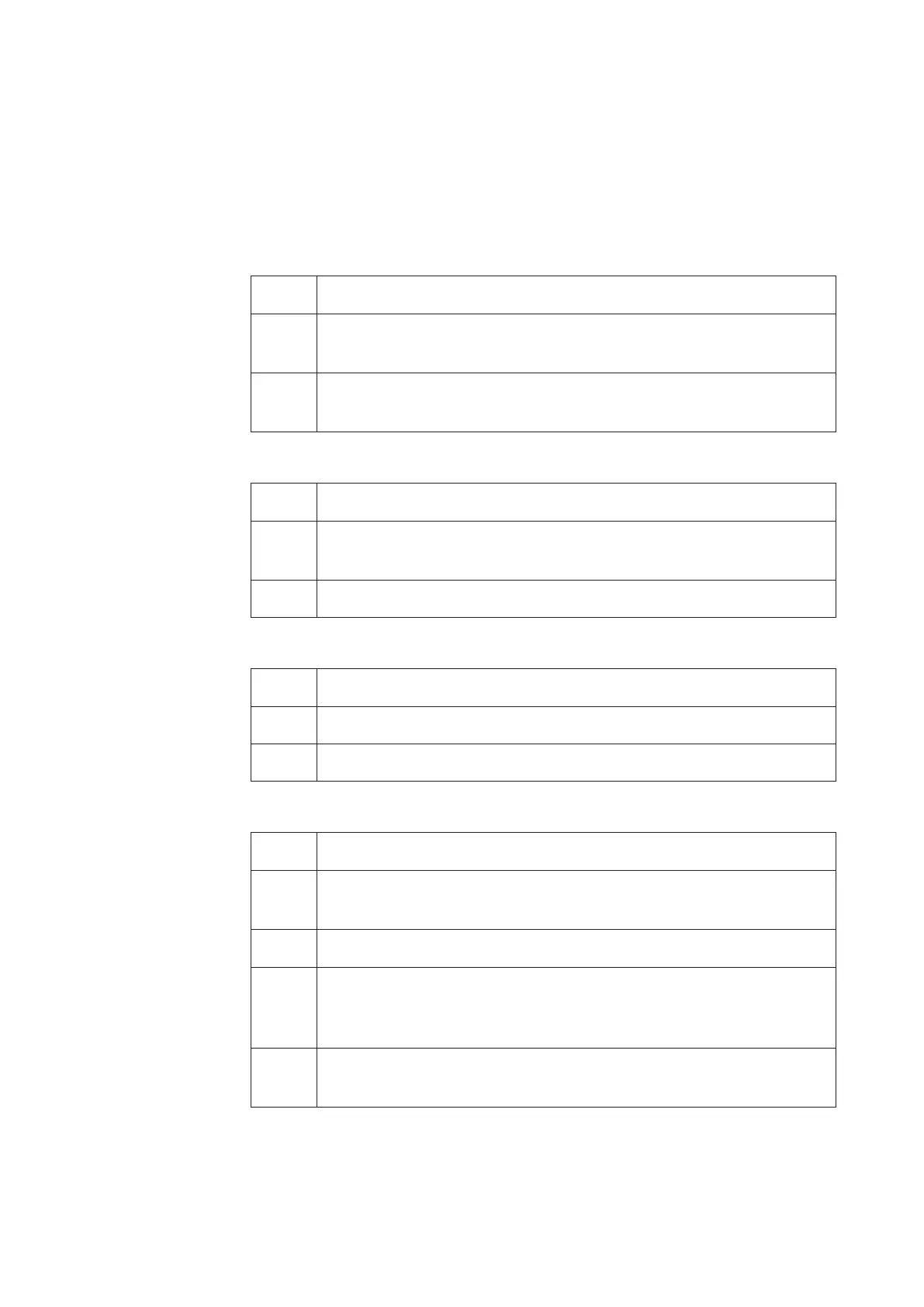

4. Removing lift stopper and spring unit

Step Procedure

1 Loosen hex stays No.4 (four syays) which fasten lift stopper No.13 and cylinder

No.14 and remove.

2 Raise lift stopper 13 straight up and remove.

3 Install eyebolts in the threaded holes on the spring receiver No.9 which is located

on the top of spring unit (M12*2) and lift spring unit (approximately 120 kg) up

with a crane.

4 While suspended by crane, remove the piston’s No.3 sealing parts (tape liner

No.14, O-ring No.15)

Loading...

Loading...