10-5

Step 7:

Being careful not to damage the surface of the stem, install the packing flange.

Step 8:

After applying the anti-seize compound indicated in Table 10-3 [Never-Seez made by Bostik,

Inc., in the U.S.] to the surface of the threads of the stud bolts and the bearing surface of the

nuts, tighten them by hand.

3. Tightening

Step 1:

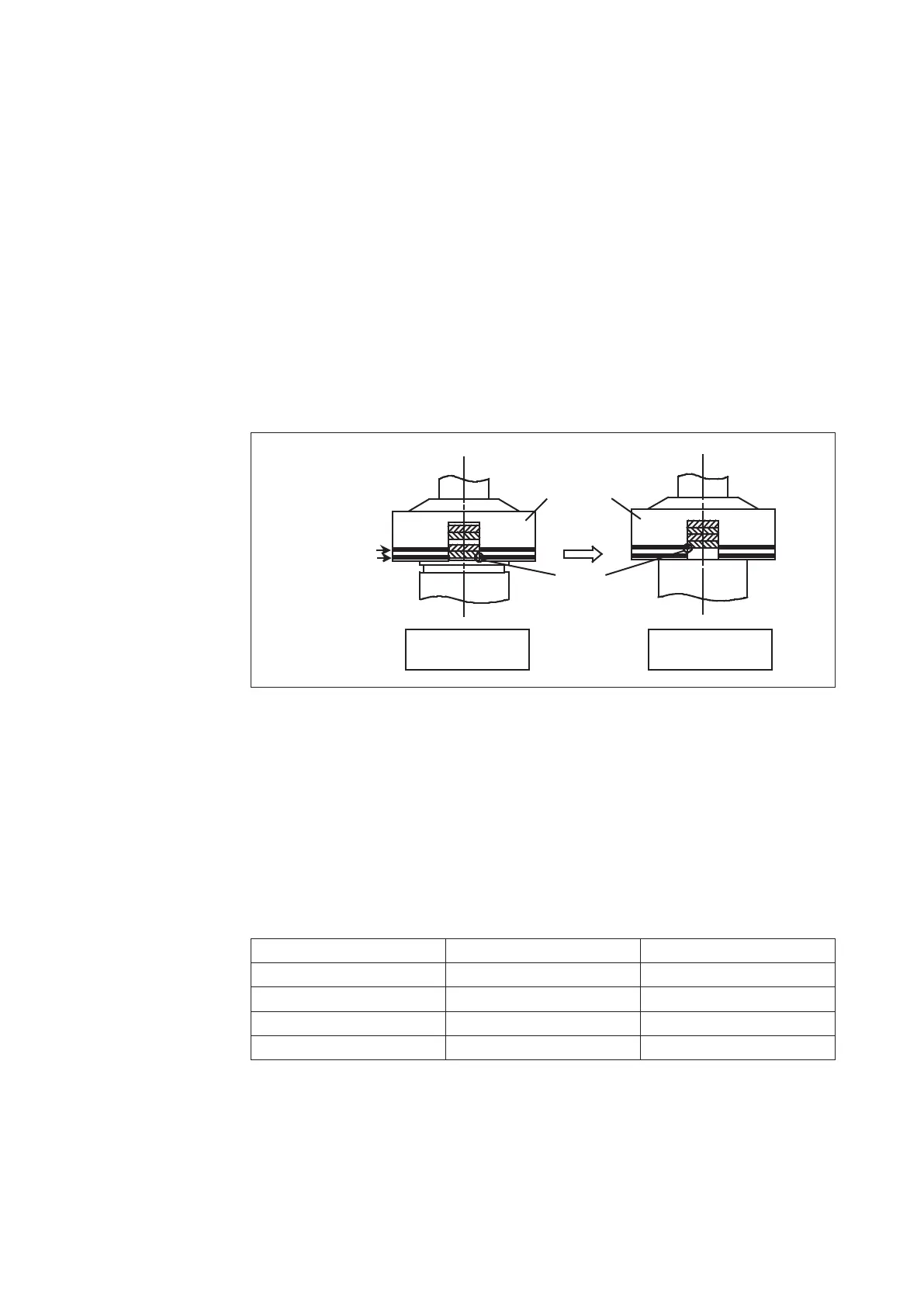

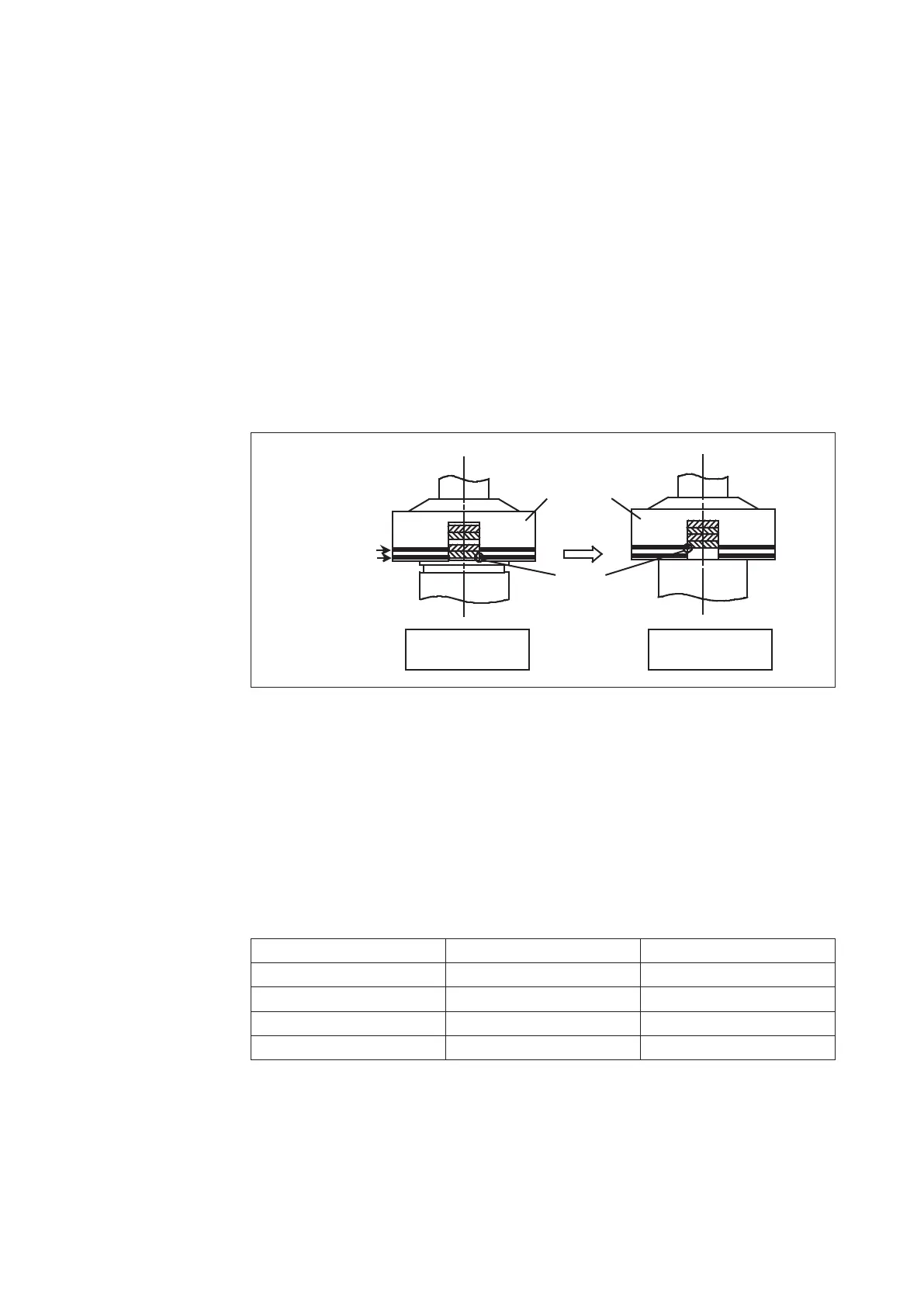

With reference to Fig. 10-5, check the position of the Belleville springs through the front

window of the spring case. When the Belleville springs are set properly, the lower edge of the

outer diameter of the lowest Belleville spring almost coincides with the lower scale mark of the

spring case. (In some cases, it does not exactly coincide because of the dimensional tolerance

of the Belleville springs.)

Front appearance

of the spring case

Scale marks

Lower edge of the

outer diameter

of the lowest piece

Before tightening

After tightening with

the specied torque

Fig. 10-5. Loading conditions of the Belleville springs

Step 2:

Tighten each of the right and left gland nuts by half a turn alternately to the specified torque.

Table 10-4 shows the tightening torque.

If the tightening torque is less than the specified value, be aware that the amount of leakage

may exceed the specified value because of insufficient tightening.

If the tightening torque is more than the specified value, be aware that the amount of leakage

may exceed the specified value in a short period of time because of the accelerated wear of the

gland packing, in addition to the increased sliding friction of the stem.

Table 10-4. Tightening torque of the gland nuts

Actuator model Stem size Tightening torque

PSA1, HA2

φ

10 mm 8 to 10 N·m

HA2, HA3

φ

13 mm 13 to 16 N·m

HA3

φ

16 mm 22 to 26 N·m

HA4

φ

20 mm 29 to 35 N·m

Loading...

Loading...