WWW.BALLUFF.COM • 1-800-543-8390

5

™

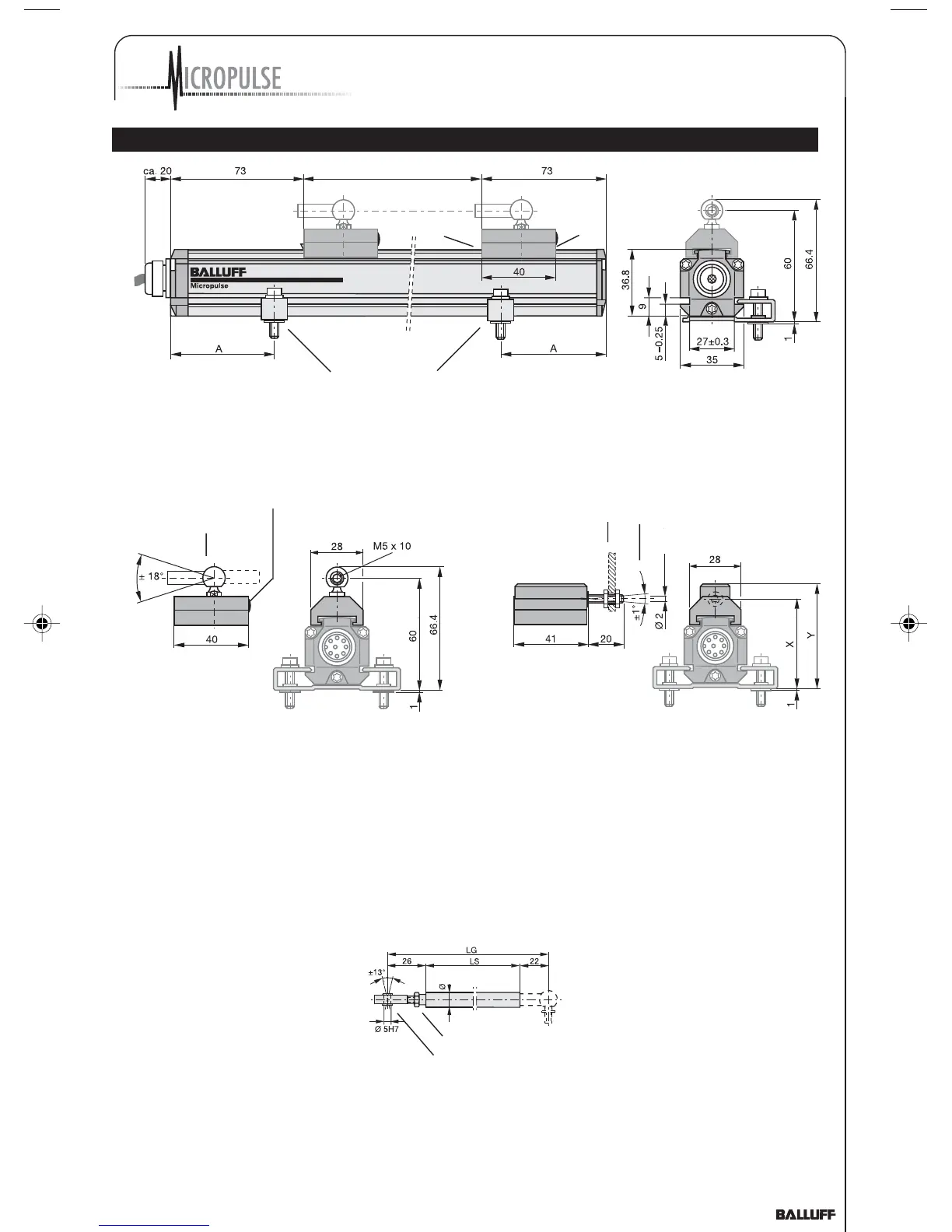

BTL5-A/C/E/G_ _-M/U_ _ _ _-P-S 32/KA_ _

Micropulse Linear Position Transducer

Analog Output/ Profile Housing

Nominal stroke

3 Installation (cont.)

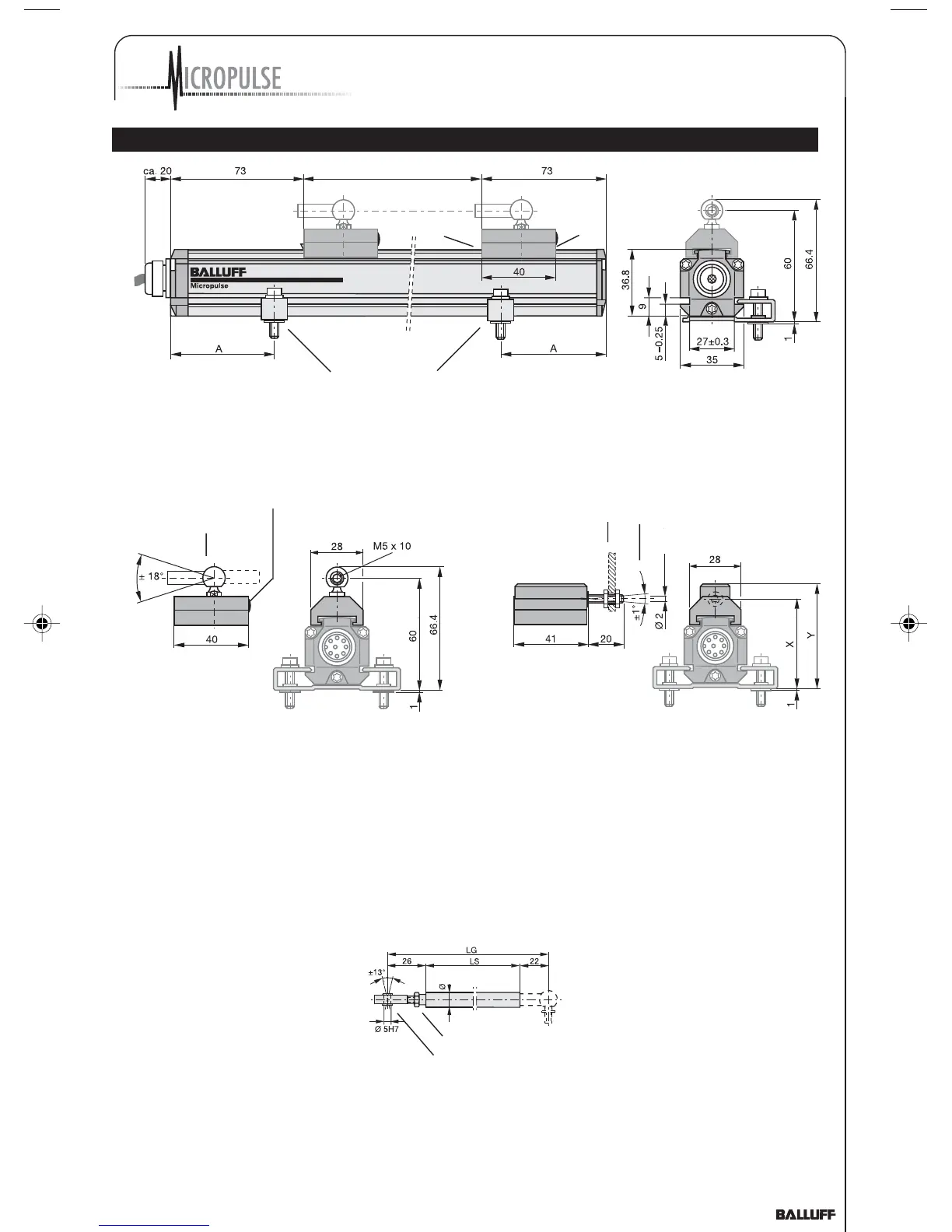

Mounting brackets with isolation bushings and M5 x 22

socket head cap screws, DIN 912,

max. tightening torque 2 Nm

NL

Black,

round

marking

Magnet

Fig. 3-5: Dimensional drawing (BTL5...P-KA transducer with captive magnet BTL5-F-2814-1S)

Ball joint "B"

DIN 71805,

rotates horizontally

Black, round

marking

Mechanically joined to M5

stud using 2 nuts

Max. angle offset

Max. parallel offset

BTL5-M-2814-1S: X = 48.5 Y = 57

BTL5-N-2814-1S: X = 51 Y = 59.5

Fig. 3-6: BTL5-F-2814-1S magnet Fig. 3-7: BTL5-M/N-2814-1S magnet

3.3 Captive magnets

Lateral forces are to be

avoided when using captive

magnets (Figs. 3-6 and 3-7).

Connections are required here

which permit the correspond-

ing degree of freedom with

respect to the direction of

movement of the magnet

along the stroke range. It is

assumed that the BTL5-F-

2814-1S magnet is connected

to the machine member using

a connecting rod. The

BTL2-GS08...A connecting rod

(Fig. 3-8) is available as an

accessory (please indicate

length LS when ordering).

Ball joint "B" DIN 71805,

rotates horizontally (part of

BTL5-F-2814-1S magnet)

Fig. 3-8: BTL2-GS08-_ _ _ _-A

connecting rod

Swivel eye DIN 648

Jam nut DIN 934 M5

08

P_Analog_122003.pmd 12/11/2003, 3:59 PM5

Loading...

Loading...