Operating instructions B-Series

Version 2.4, En Page 73 of 81 21-10-2005

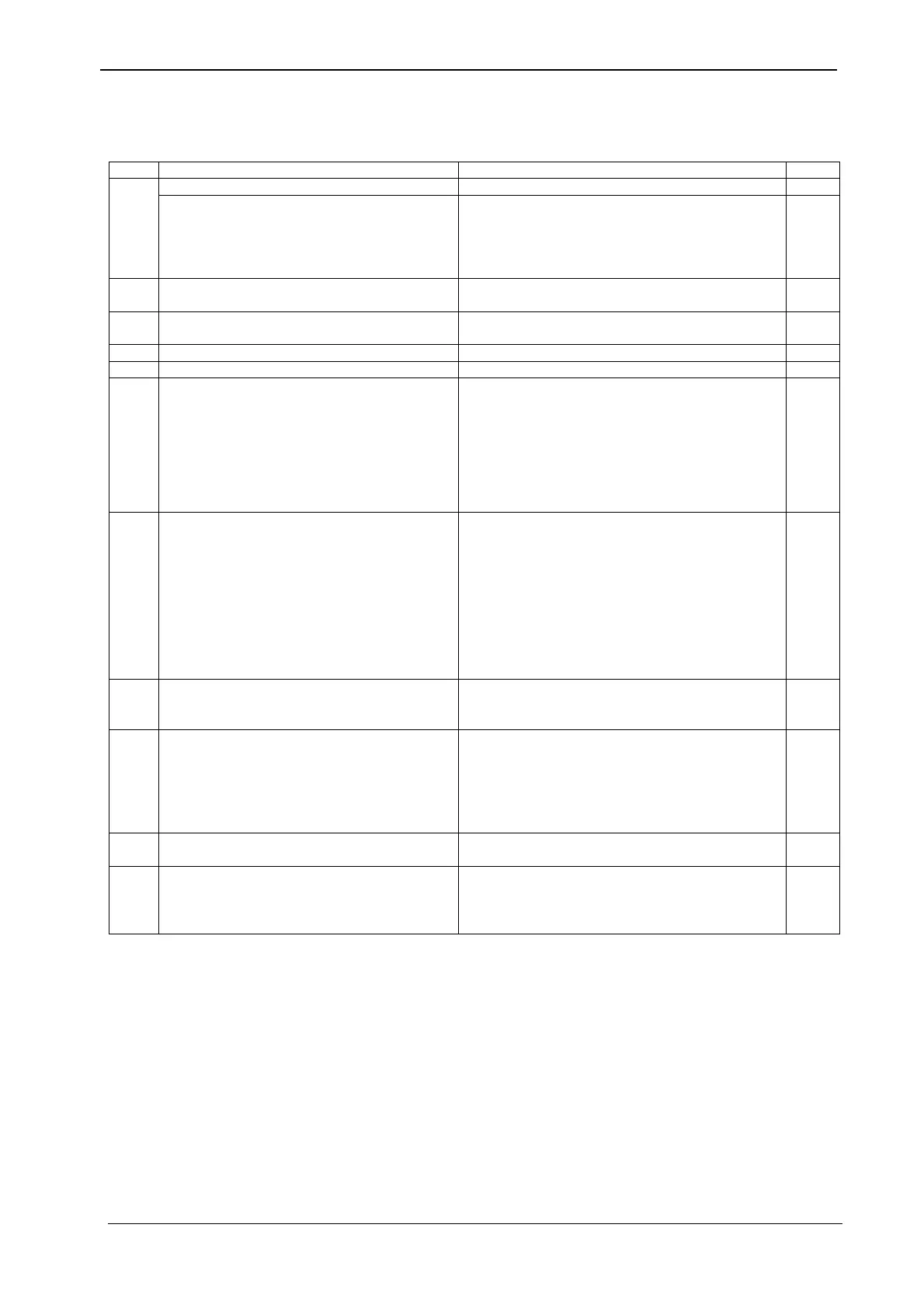

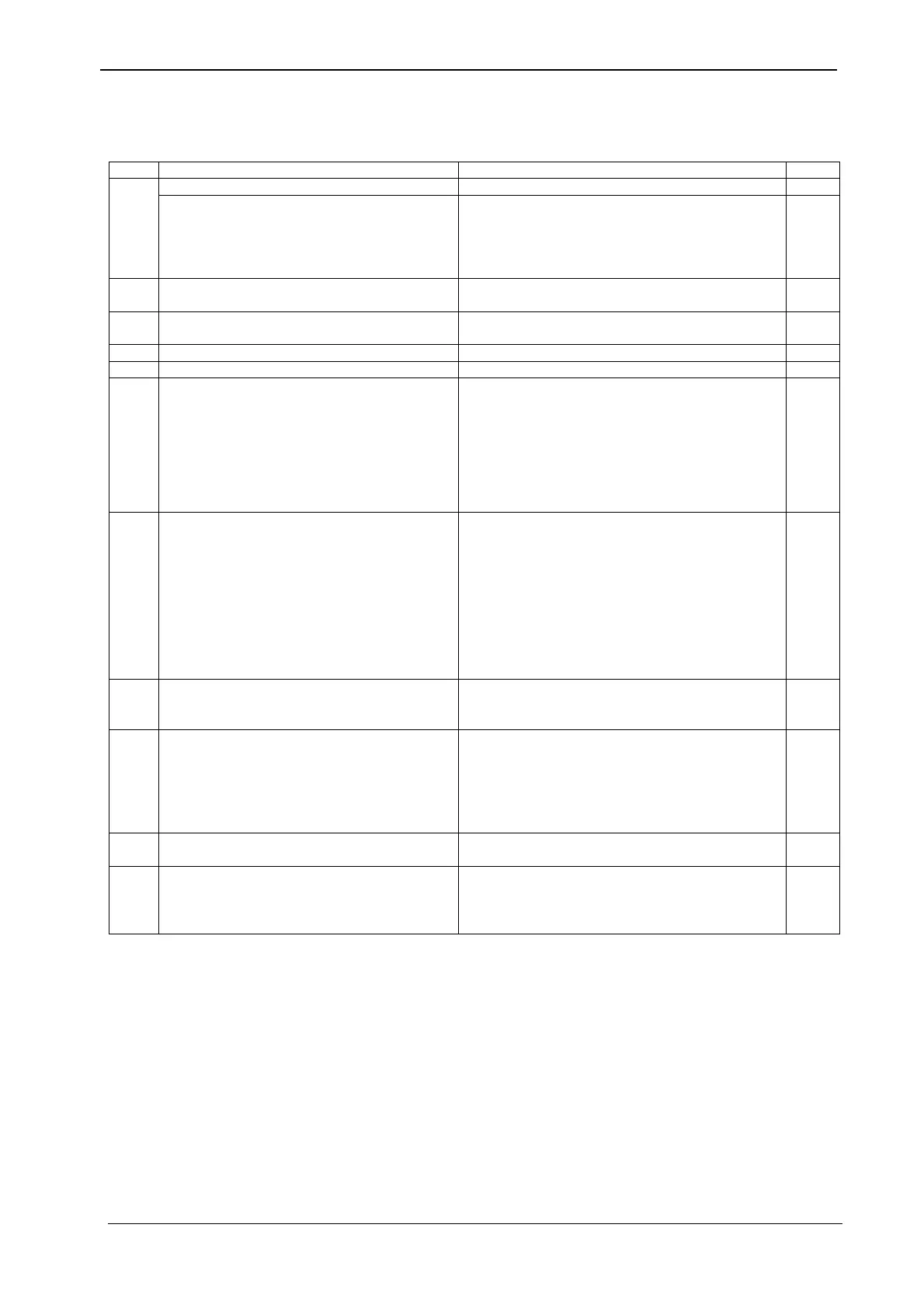

12 Summary of instructions for ATEX pumps

Code Requirement Supplementary remark OK?

K1

Choice (Selection) pump

Ensure a correct pump choice with respect to the

liquid type with its technical properties and

quantity.

With flammable, volatile liquids: ensure the correct

choice of material for the rotor and wear plate

(according to EN 13463-5:2003 §5.2, note 2).

• Make sure that the pump housing, etc. is not

adversely affected by the medium to be pumped.

K2 Ensure a correct suction line in relation to the

NPSH curve.

K3 Ensure sufficient counterpressure on the delivery

side so the pump does not run outside the curve.

K4 Ensure a good pipe diameter.

K5 Ensure a good inflow opening in the suction line.

K6a Ensure a correct mechanical shaft seal choice for

the liquid to be pumped.

Correct lubricant

• Checks (by temperature monitoring)

• Maintenance

• The ignition temp. of coolant must be at least 50 K

above the max. surface temp. of the pump (EN

13463-5:2003 §4.5).

• Provide a seal with extra guarantee against leakage

when pumping volatile liquid.

K6b Ensure a correct auxiliary system for the

mechanical shaft seal.

Take account of the flow rate and pressures in the

pump.

• Take account of the interaction of auxiliary liquid

with the medium to be pumped.

• The auxiliary system must itself be EX, cat. 2. Here

also note:

• What is the outside temp. of the auxiliary

system?

• Can the auxiliary system guard against the

build-up of ignitable gas inside?

K6c Use the correct packing

Take account of pressures in the pump.

• Take account of the interaction of packing with the

medium to be pumped.

K6d Ensure the correct choice of retaining ring

Retaining rings may contain no light-metals.

• The following materials are allowed:

• Elastomers, etc.

• PTFE

• Graphite

• Ceramics

K7 Make sure that dirt particles in piping systems

cannot cause blockages.

Fit a filter if necessary

K8 Make sure you choose the right coupling.

The coupling must be sufficient for the power and

number of revolutions.

• The coupling must be EX, cat. 2

• Follow the instructions of the manufacturer.

Loading...

Loading...