Operating instructions B-Series

Version 2.4, En Page 77 of 81 21-10-2005

13 safety devices.

Extra point(s) for attention with ATEX pumps.

Always assemble the correct safety devices for the correct ATEX environment.

Environmen

t

Type of sensor

Gas Ex II 2G T4

Dust Ex II 2D T4

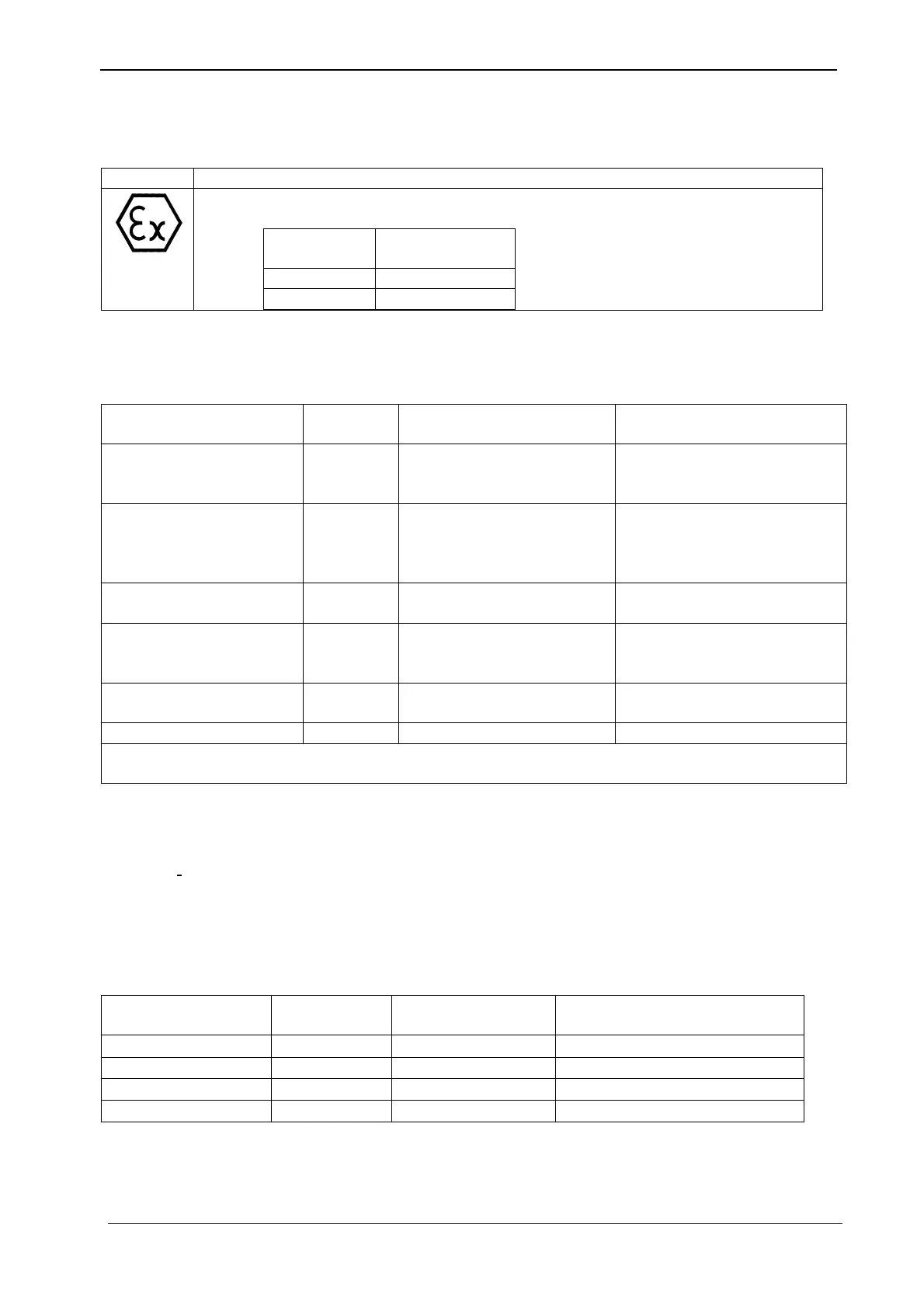

13.1 Summary of safety devices to be used

The table below summarises when which safety devices must be used:

Safety device Paragraph

Category 2

(zones 1, 21)

Category 3

(zones 2, 22)

Temperature monitoring

In the intermediate

housing

13.2 Always Not required

Temperature monitoring

at the ball bearing

13.2 Only with not lifelong

lubricated greased bearings

that are not regularly

lubricated.

Only with not lifelong

lubricated greased bearings

that are not regularly

lubricated.

Coolant monitoring 13.3 Only when pumping volatile

liquid.

Not required

Overpressure protection 13.4 Only required when

pumping volatile liquid

and/or dangerous liquid.

Not required

Underpressure protection 13.5 Only when pumping volatile

liquid.

Not required

Safety devices E-motor 13.6 Always Always

Caution: safety control (drive) must suffice with regard to certain requirements. See paragraph

13.7

13.2 Temperature monitoring:

Assemble a temperature sensor (PT100) in the intermediate housing (Only with Cat. 2 pumps).

If applicable: assemble a temperature sensor (PT100) with not lifelong lubricated greased bearing if this is

not regularly lubricated.

The temperature sensor switches the pump off at the set temperature.

Set the sensor according to the table for the category:

Temperature

category.

Temperature. Safe sensor setting Maximum permissible liquid

temperature

T1

450

C 370

C 180

C

T2

300

C 230

C 180

C

T3

200

C 140

C 120

C

T4

135

C 80

C 65

C

The same temperatures apply for category 3, but no temperature sensor needs to be fitted in the

intermediate housing.

Loading...

Loading...