Operating instructions B-Series

Version 2.4, En Page 76 of 81 21-10-2005

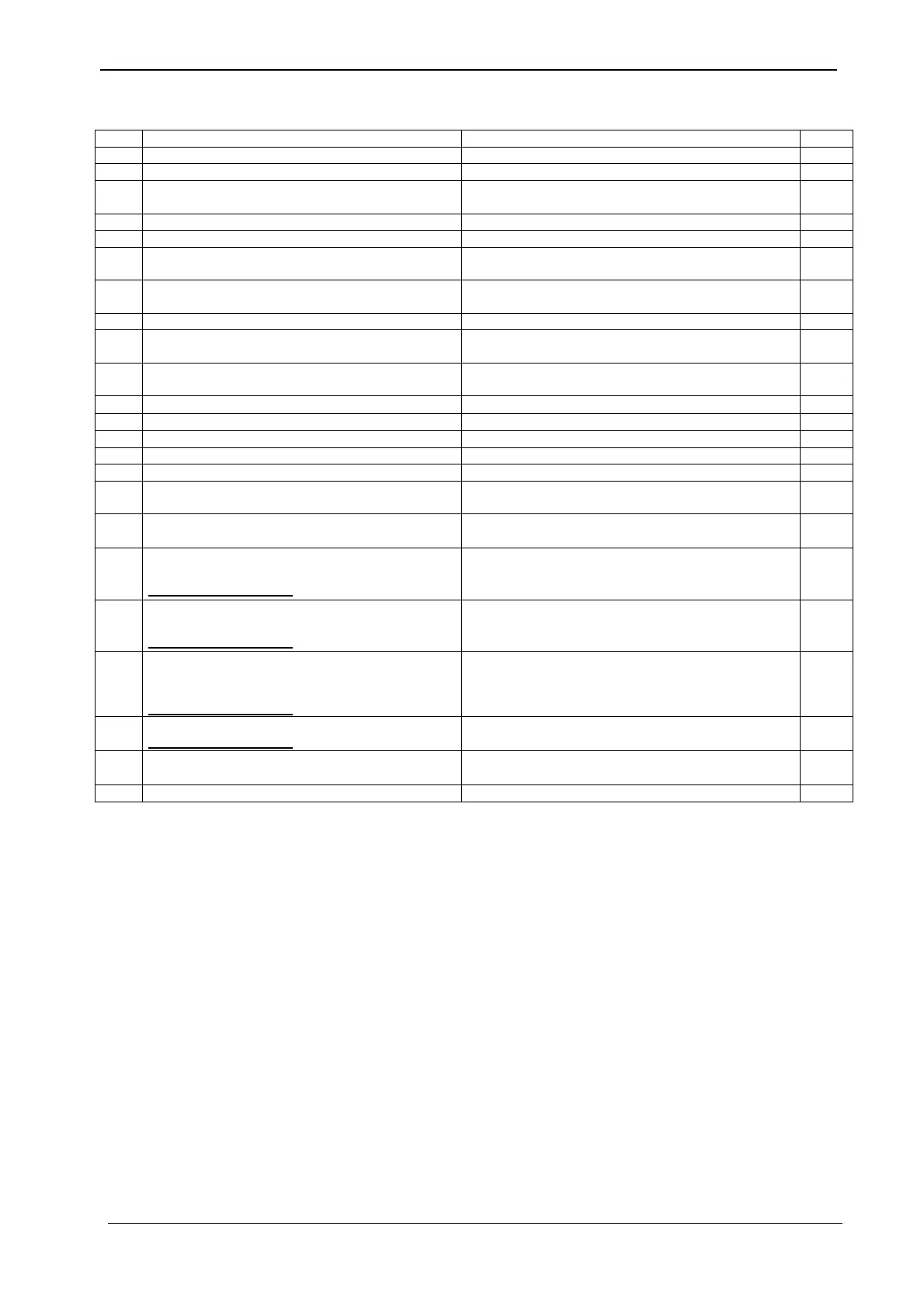

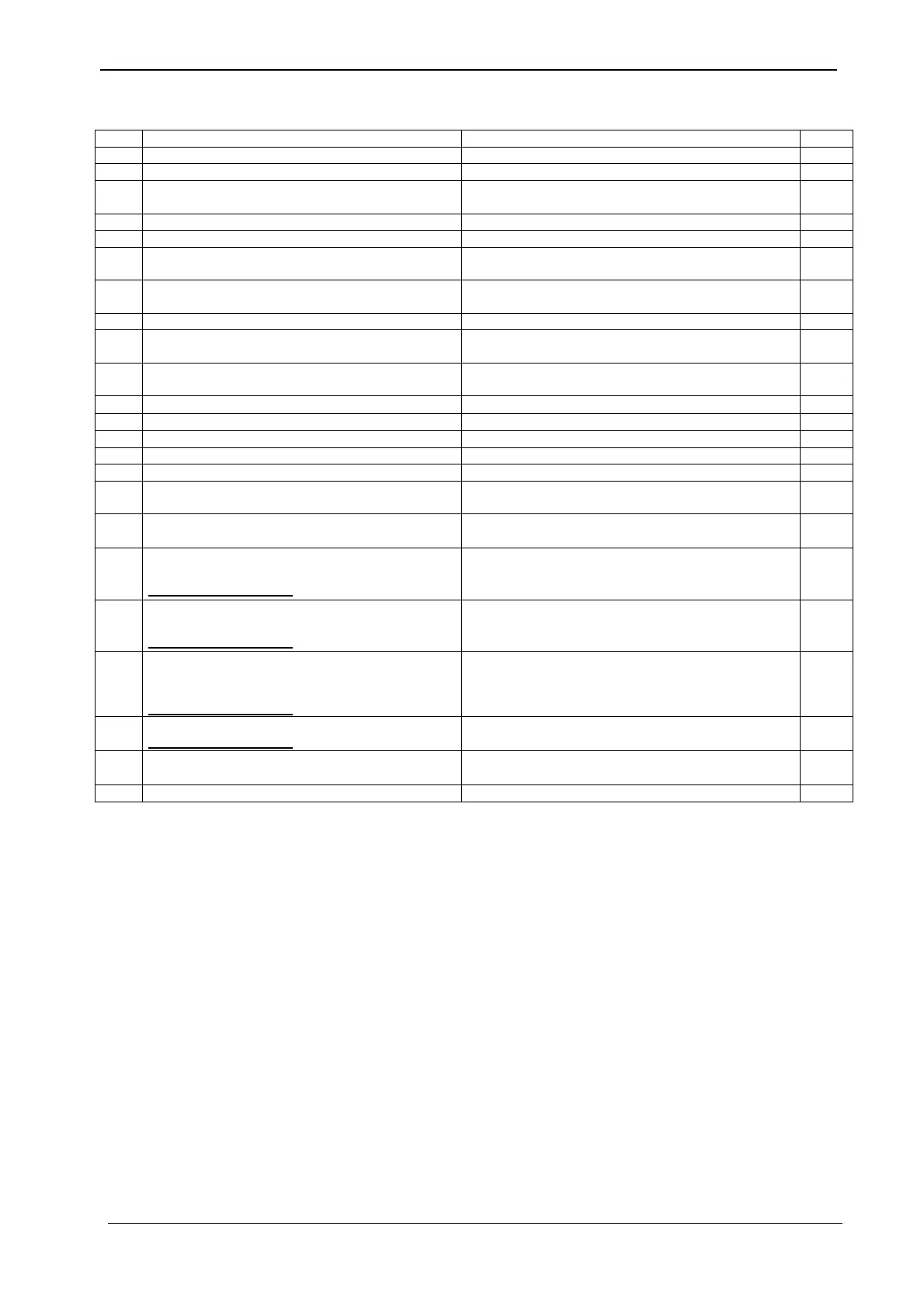

Code Requirement Supplementary remark OK?

Service/Maintenance

S1 Regularly check the packing for leaks.

S2 Ensure a good lubrication schedule (only with oil-

lubricated bearings).

S3 Regularly check for bearing play.

S4 Ensure a good service plan

S5a Check oil level (according to (EN 13463-5:2003 §6.2)

(Only with oil-lubricated bearings)

S5b Check coolant level (according to EN 13463-5:2003

§5.4).

S6 Check for bearing leaks.

S7 If a leak occurs to the mechanical shaft seal: stop the

pump.

S8 Regularly check the coupling and elastomers of the

coupling.

S9 Ensure the correct spare parts

also ensure correct fitting with shaft and bush

S10 Check alignment, damage to protective cover

S11 Regularly check the safety devices on the pump (unit)

Safety device

B1 Ensure direction of rotation protection

(electrical/mechanical).

B2a Ensure regular checks for leakage and adjust if

necessary.

This applies for:

• the auxiliary system

B2b Choice of seal only to be determined after consultation

with the supplier.

(Only with Cat. 2 pumps)

With extra guarantee against leakage.

• Only when pumping volatile liquid.

• Apply safety device for coolant presence.

B4a Protect the pump against overpressure. Set the max.

pressure to 10% above the original pump curve.

(Only with Cat. 2 pumps)

Only required when pumping volatile liquid and/or

dangerous liquid.

• Or with a dangerous liquid.

B4b Protect pump against underpressure. The maximum

suction head depends on the NPSH value indicated on

the pump curve.

(Only with Cat. 2 pumps)

Only required when pumping volatile liquid.

B5 Protect pump against temperature.

(Only with Cat. 2 pumps)

Bearing temperature.

• Mechanical shaft seal.

B6 Protect electric motor against overloading

In the case of overloading the motor may not become

too hot. This is the case with an ATEX motor.

B7 Protection of supplied power.

Loading...

Loading...