Operating instructions B-Series

Version 2.4, En Page 75 of 81 21-10-2005

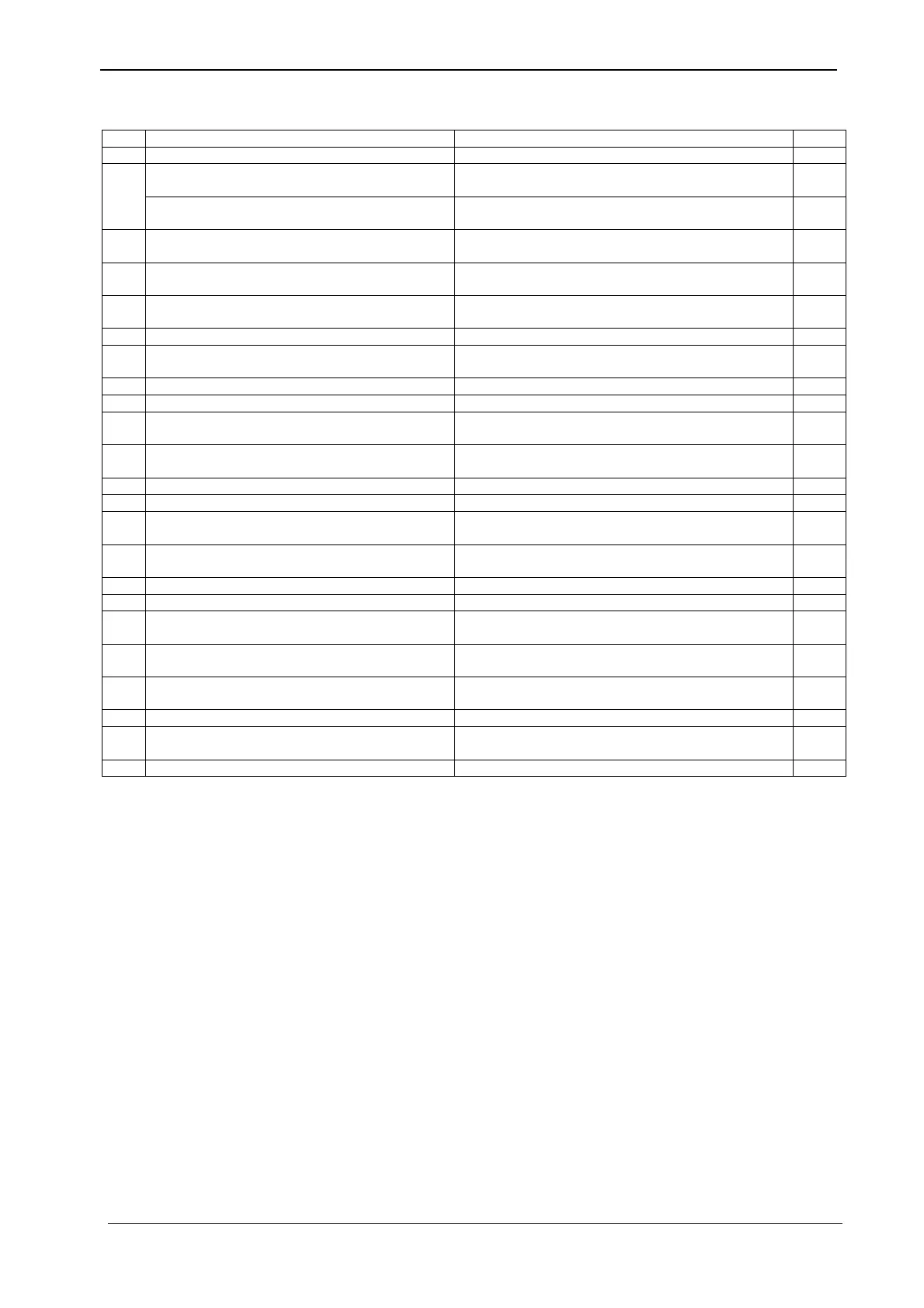

Code

Requirement Supplementary remark OK?

Installation

P1

P2a

Do not expose the pump to higher pressures than

which the pump is suitable according to the curve.

Prevent dirt particles in the medium (only clean

filtered medium allowed)

With volatile, flammable liquids only a clean, filtered

medium may be used)

P2b Prevent dirt particles larger than the dirt passage of

the rotor from arriving in the suction line and pump.

P3 Make sure that the pump (unit) is mechanically well

shielded while operating.

P4 Make sure that pump is installed without any

stresses.

Including coupling and E-motor.

P5 Ensure the correct coolant for mechanical shaft seal.

P6 Ensure the correct coolant and temperature for the

medium to be pumped.

P7 Make sure the rotation direction arrow is present.

P8 Connection between pump and ground (earthing).

P9 Ensure the good alignment of the pump and drive

gear.

P10 Ensure the good fitting of the coupling on the pump

shaft and drive gear.

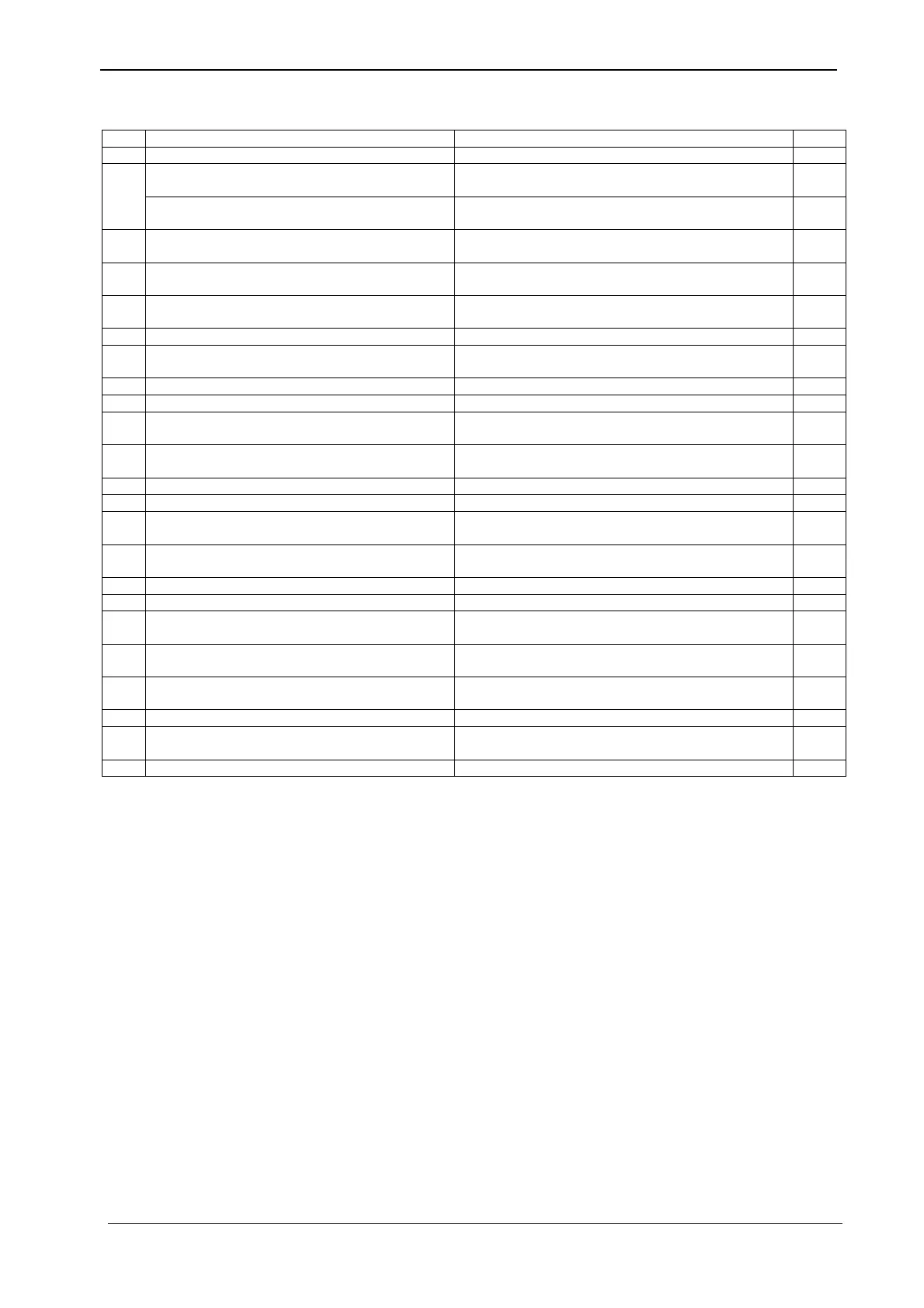

Startup/Use

G1 Prevent pump being exposed to temperatures below

freezing point if it is filled with liquid.

G2 Make sure that liquid supply to the pump is smooth

and oxygen-free.

G3 Ensure the correct direction of rotation.

G5 Prevent the pump for dry running.

G6 Make sure the pump does not pump against a closed

valve.

G8 Make sure that the pump is filled with liquid at the

correct temperature.

G9 Make sure that the mechanical shaft seal

cooling/lubrication is in good working order.

G10 Ensure sufficient coolant

G11 Prevent the sudden closing of valves so a water

shock originates.

Loading...

Loading...