19

Emergency Reserve Manifold

2005715.05

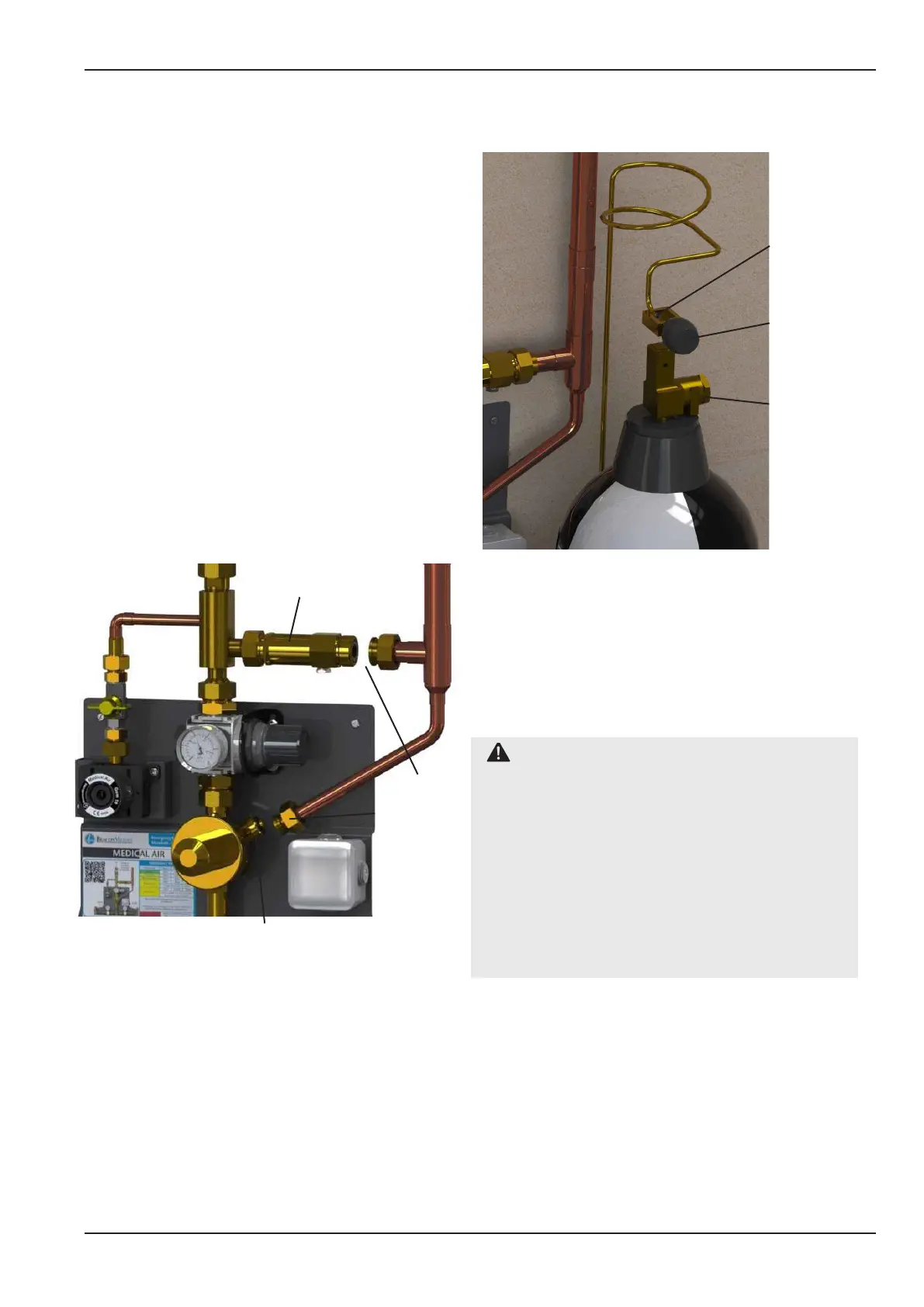

5.3.5 Close one cylinder valve and disconnect

the tailpipe at the cylinder end (see gure

15). Listen for a leak from the tailpipe. A minor

leak is permissible and likely but an obvious major

leak denotes failure of the manifold non-return

valve (NRV). If the latter happens, do not totally

detach the tailpipe but instead retighten it and test

other tailpipes in the same way. Any failed NRV’s

can be replaced (see section 6.8) after all cylinder

valves have been closed and the system has been

depressurised. Repeat this test when the new

NRV’s have been tted (See gure 15 and section

4.7 - Cylinder Operation).

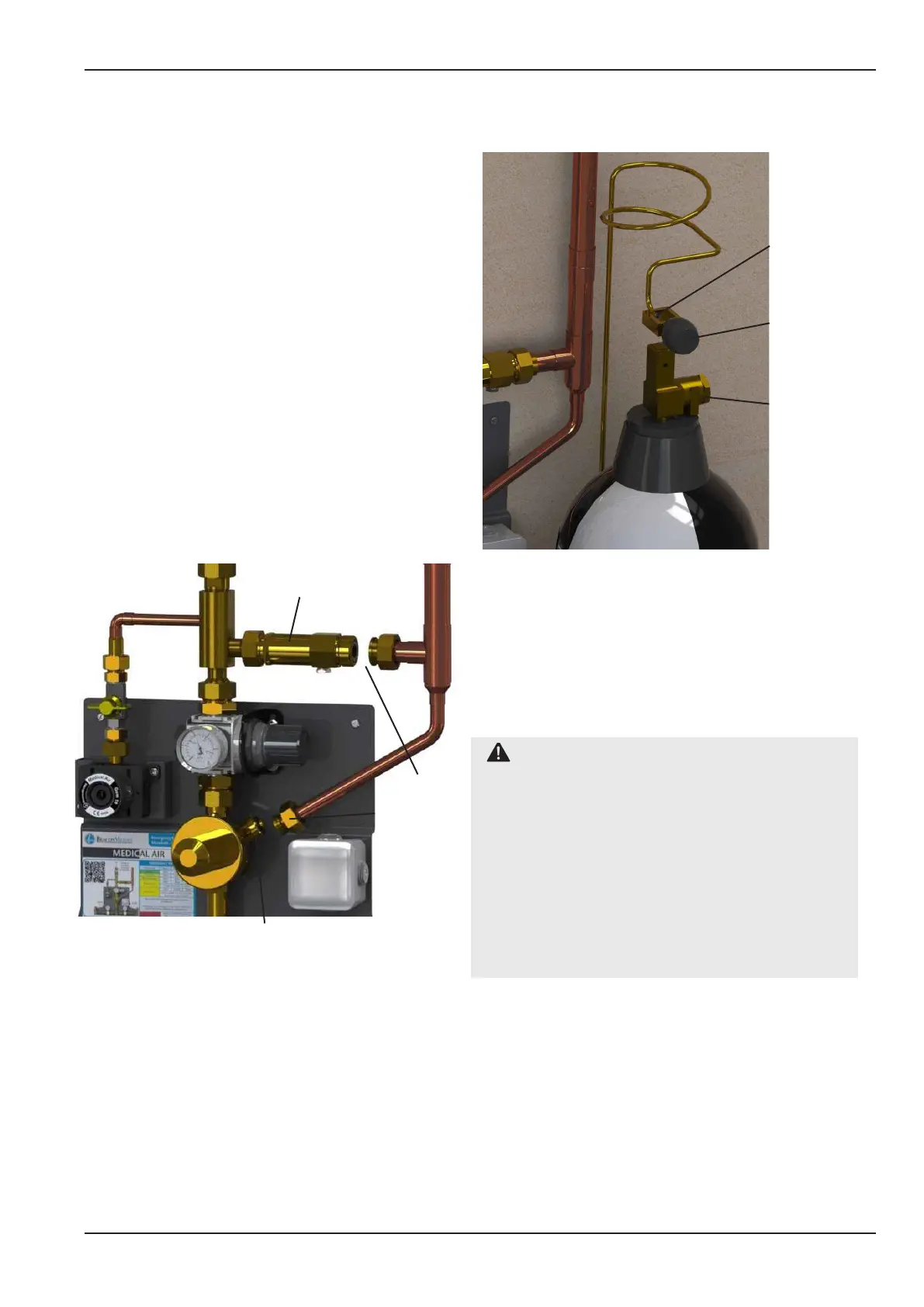

Figure 14 - Relief Valve Inspection

Flat face

connector

with O-ring

seal & swivel

nut

1st stage relief valve

2nd stage relief valve

Figure 15 - Manifold header Non-Return Valve

Inspection.

Tailpipe to

cylinder

connection

Typical Cylinder

Valve

Bodok Seal

(b) all system pressures are normal;

(c) all alarms are showing “green” normal

lamps;

(d) the automatic manifold main isolating

valve is open; and

(e) the manifold is supplying the hospital.

5.3.2 Close the isolating valve on the ERM slowly

and conrm that there is no eect on the line

pressure to the hospital.

5.3.3 Open all cylinder and header high-pressure

isolating valves.

5.3.4 Check that the ERM safety valves are

not passing, by disconnecting their downstream

exhaust coupling and inspecting for a gas leak and

check the condition of the seals (See gure 14).

Replace the valve or seals as necessary. Reconnect

the exhaust pipework, ensure the O-ring seals

correctly in place.

5.3.6 Ensure the line valve ‘B’ is closed and one

cylinder and bank valve on 1 side of the ERM is

open (see gure 1). Open Valve ‘C’ and probe

the sampling outlet to produce a steady ow and

check the pressure on the line gauge does not dip

by more than 10%. If possible attach a owmeter

to the sampling outlet and pipe away to a safe

location while performing this test. Close valve ‘C’

when nished.

CAUTION:Foranaestheticandoxygen

manifolds ensure that the manifold room is well

ventilated and no potential ignition sources are

present while running this test. Run this test

forasshortatimeaspossible.Oxygencanbe

absorbed into clothing etc., so once the test is

complete it would be recommended to spend at

least20minutesoutdoorstoensuretheoxygen

has released. During this time stay away from

nakedame,donotsmokeetc.Donotperform

this test unless the risks can be kept within an

acceptable level.

5.3.7 Check the static pressure of the regulator

(should be typically as per table 4 in section 4).

Observe this pressure for typically 10-20 minutes

to ensure that there is no regulator creepage.

Excessive creepage will necessitate replacement

(see section 6.3) and a repeat of this test.

5.3.8 To test the “reserve low” contact gauge,

open one cylinder/header isolating valve until the

cylinder content gauge indicates full pressure, and

then close the valve.

Loading...

Loading...