21

Emergency Reserve Manifold

2005715.05

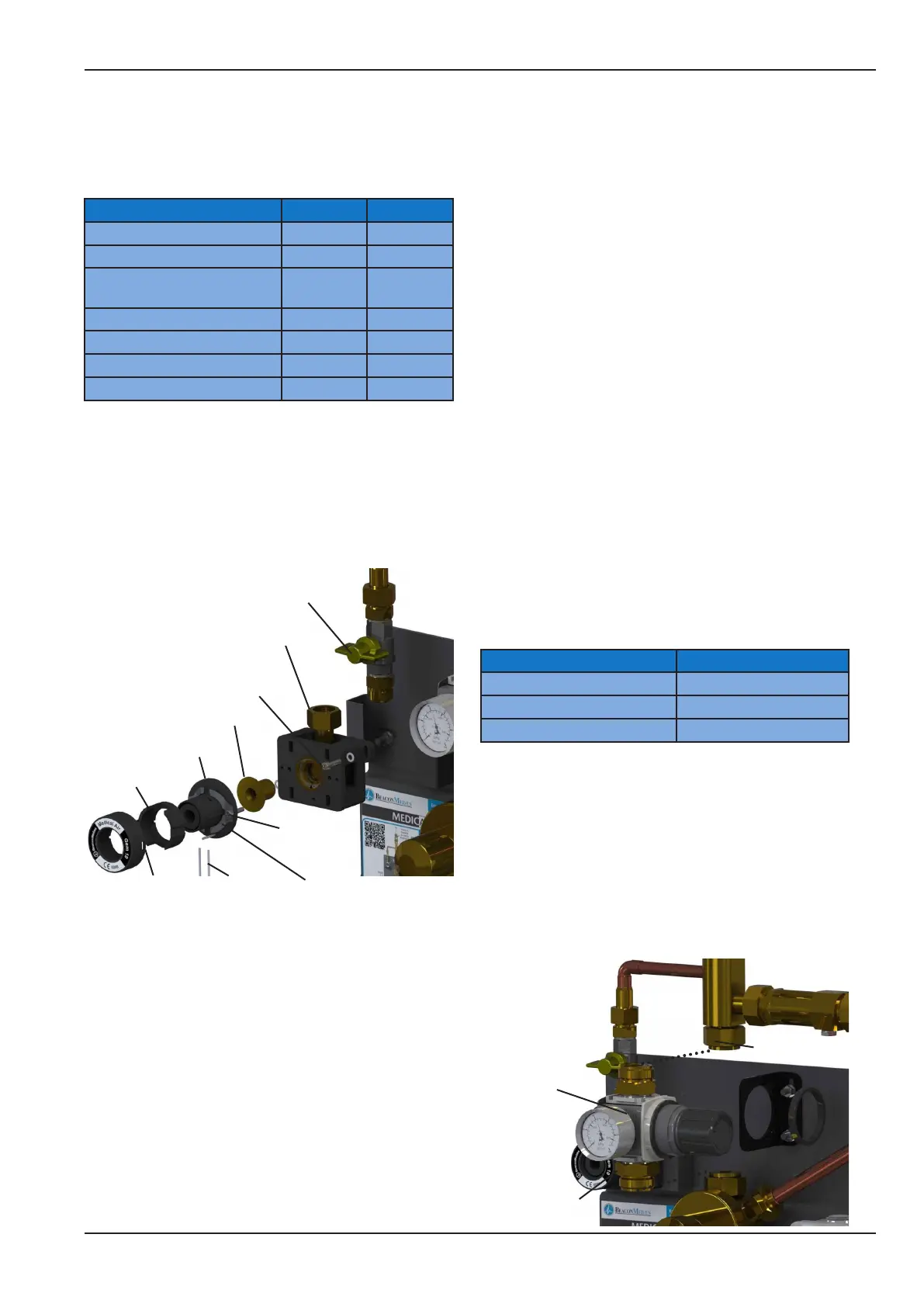

6.2 Replace Sampling Outlet (See

table 6 for part numbers)

Table 5 : Sampling Outlet Part Numbers

GAS Type 1st Fix 2nd Fix

Oxygen (O2) 2005810 1826850

Nitrous Oxide (N2O) 2005811 1826851

Oxygen/Nitrous Oxide (O2/

N2O)

2005812 1826852

Medical Air 2005813 1826853

Surgical Air 2005814 1826854

Nitrogen (N2) 2005816 2004835

Carbon Dioxide (CO2) 2005815 2004836

6.2.1 The Sampling outlet can be worked on

without taking the ERM o line.

6.2.2 Ensure the sampling outlet isolation valve

‘C’ is closed (as shown in gure 17).

6.2.3 Probe the outlet to depressurise.

6.2.4 To replace the whole outlet, disconnect

the 1/2” connection and remove the 2 x M4 cap

head set screws. Ensure the replacement unit is

the correct gas type. Replace the new outlet by

connection the 1/2” connection ensure the O-ring

is in place (Replace if damaged, see gure 17 for

part number. Secure the unit with the M4 cap

head and washers.

6.2.5 For replacing the 2nd x only (see gure

17). Press the fascia ring clips shown and slide

it from the release ring. Press the release ring,

compressing the locking spring until the roller pips

fall out. Remove the 2nd x fasteners and slide of

Figure 17 - Sampling Outlet Replacement

1 x 1/2” at face connection

with swivel nut and O-ring seal

(Seal P/N: 1823637)

Isolation Valve ‘C’

(Shown in closed position)

Fascia ring clips

Release ring

Roller Pins Locking spring

1st x fastener

2nd x

fastener

Check Valve

Gas specic

the 2nd x and check valve capsule.

Fit the new check valve, gas specic socket and

locking spring. Secure in place with the 2nd x

spring. Ensure the spring can be compressed

without catching the sides of the gas specic

socket, adjust as required. Fit the release ring and

compressing the locking springs till the roller pins

can be tted, then release. Fit the fascia ring so

that the clips are secured.

6.2.6 After replacing the sampling outlet

(entire outlet or just the 2nd x) probe the outlet

to ensure the locking mechanisms functions

correctly.

6.2.7 Open valve ‘C’ and check for leaks. If leaks

are found, before attempting to rectify close valve

‘C’ and probe the outlet to depressurise. Repair

the leak and repeat steps in 6.2 as required.

6.2.8 Close valve ‘C’ when replacement

complete.

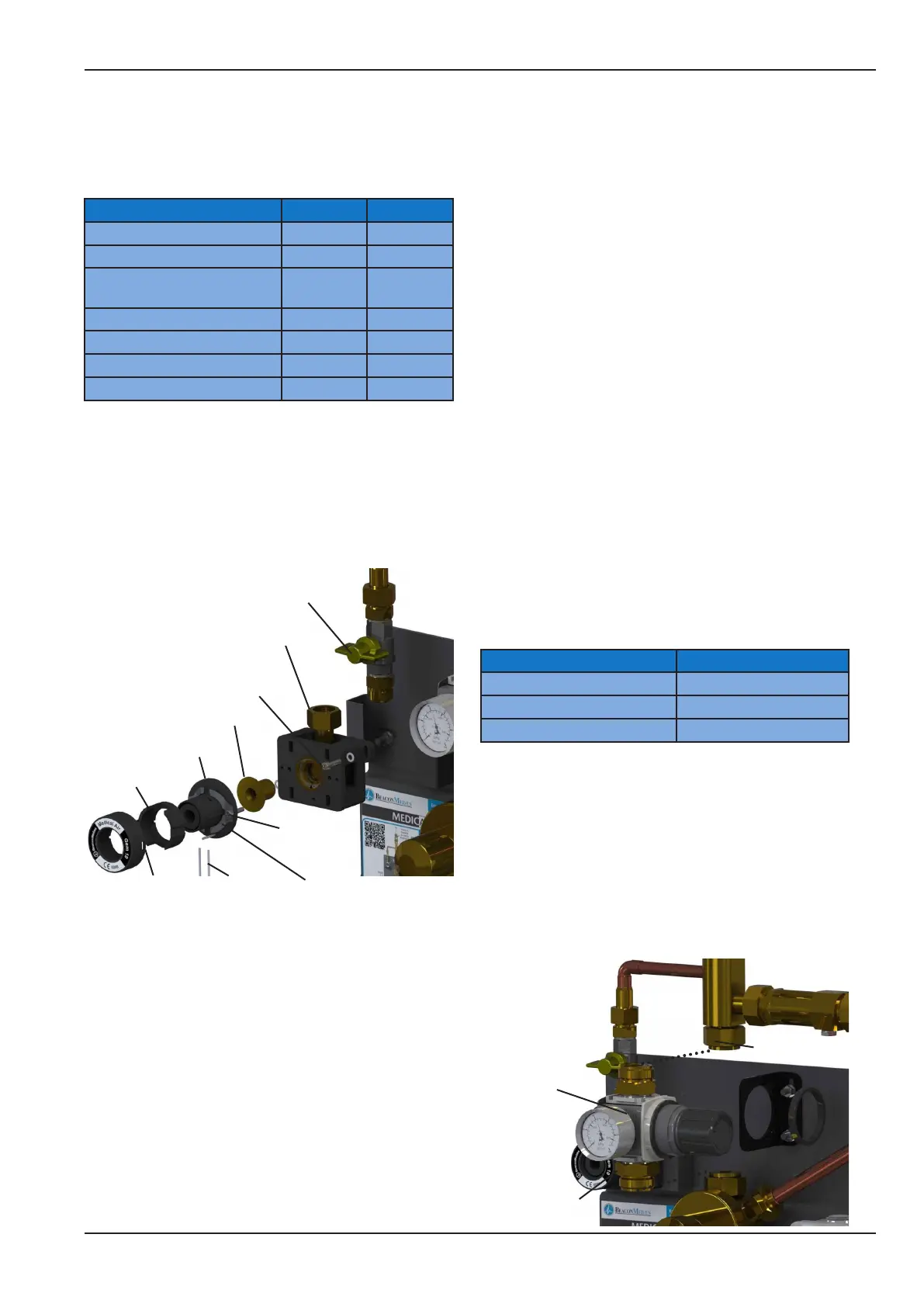

6.3 Replace 2nd stage regulator

(See table 7 for part numbers)

Table 6: 2nd Stage Regulator Part Numbers

Regulator Nominal Pressure Part Number

4 Bar 2005689

7 Bar 2005690

11 Bar 2005691

6.3.1 Complete steps in section 6.1 before

carrying out any component replacement on the

ERM.

6.3.2 Slowly turn the swivel nut of the top 1”

connection. If the you hear gas escaping do not

fully unscrew the joint until the system is fully

drained.

Locking Nut

2nd Stage

Regulator

2 o 1/2” BSP

x 1” Flat face

connector with

O-ring (2000152)

and bonded seal

(1825637)

Figure 18 - 2nd Stage Regulator Replacement

Loading...

Loading...