16

Emergency Reserve Manifold

2005715.05

3. Commissioning

3.1 General

Commissioning of the ERM must be carried

out in full after initial installation. The object of

the commissioning procedure is to ensure that

all components are serviceable and that the

overall system is operable and set to the correct

distribution pipeline pressure. Suitably qualied

competent personnel who are familiar with this

manual must only undertake commissioning of the

ERM.

3.2 Preparation

3.2.1 Ensure that all tailpipes are connected to

the cylinders and manifolds on both sides and

that the restraint chains are secure around the

cylinders.

3.2.2 Ensure that the outlet pipe from the ERM is

connected to the distribution system of the same

gas service, downstream of the main supply unit

and isolation valve ‘A’ (shown in gure 2).

3.2.3 Ensure that the ERM isolation valve ‘B’

(shown in gure 1) is tted and in the closed

position.

3.2.4 Open all cylinder valves on the ERM.

3.2.5 Fully open the high-pressure isolation

valves 1 and 2 (shown in gure 1).

3.2.6 Check connections on the headers,

tailpipes, regulator and associated pipework for

leaks.

3.2.7 Fully close the right-hand high-pressure

isolation valve 2 (gure 1 & 2).

3.3 Pressure Checks

3.3.1 Ensure that full gas cylinder pressure is

shown on the cylinder contents gauges (Fitted to

valve 1 & 2, see gure 1).

3.3.2 With Valve ‘B’ closed and valve ‘C’ open,

exhaust a quick blast of gas from the sampling

outlet, close valve ‘C’. Check that the pressure on

the pipeline distribution pressure gauge is typically

as per table 4. Adjust as necessary.

Note...For reducing the pressure set point, ensure

valve ‘B’ is closed and sampling outlet isolation

valve ‘C’ is open. Gently bleed the gas from the

sampling outlet while making adjustments, as the

4. Principles of Operation

4.1 General

The ERM line pressure is set below the normal

operating range of the primary supply. While the

primary supply is functioning within it’s design

limits, the ERM will not feed gas into the pipeline.

If the primary supply fails, causing the pipeline

pressure to fall to the ERM’s set point it will

automatically start feeding gas to the pipeline.

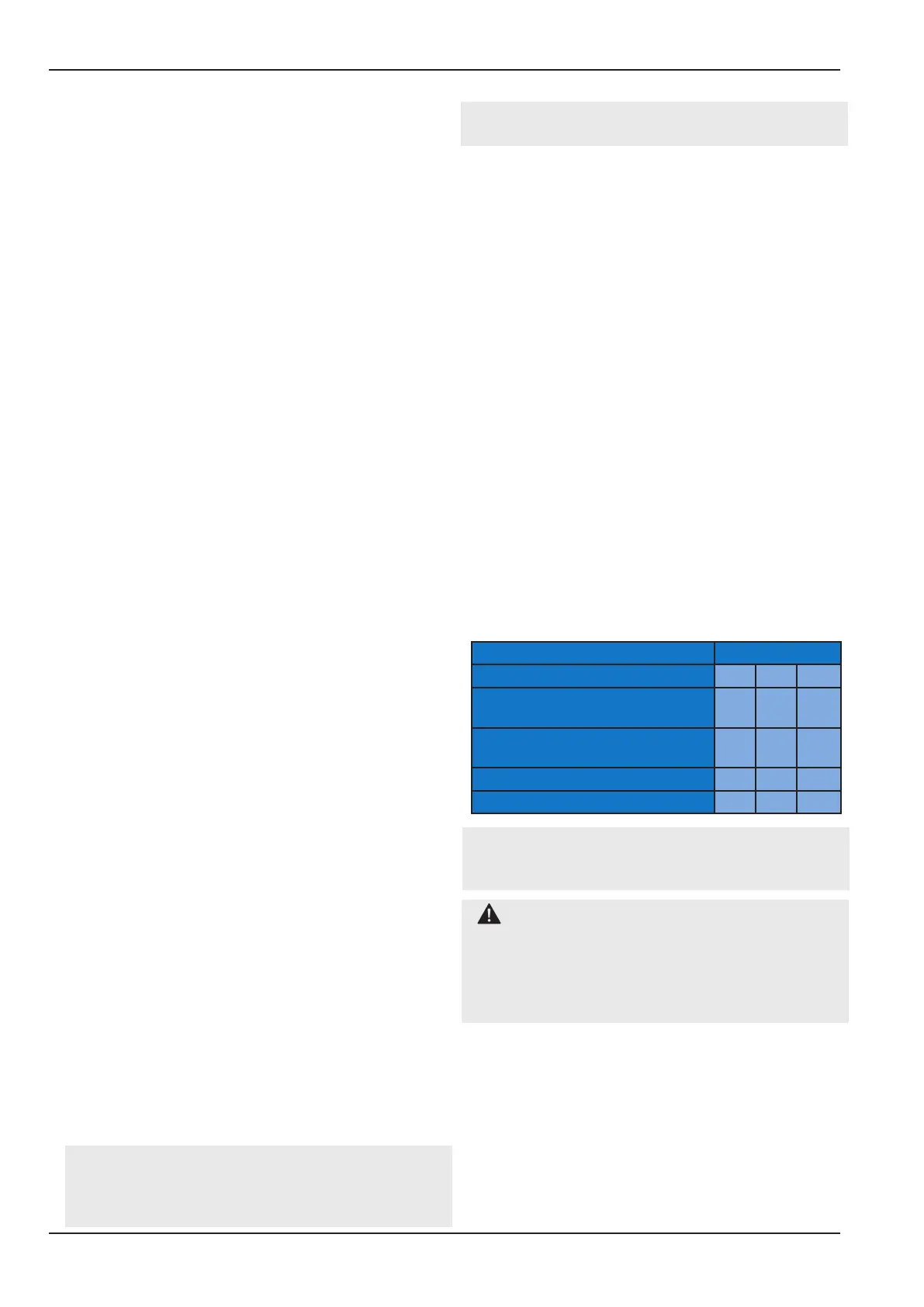

Table 3: Typical pressure settings for HTM02-

01 primary and emergency medical gas

supply system, during normal pipeline system

operation.

Pressure (Bar)

Nominal System Design 4 7 11

Max. Static Pressure Primary

Supply

4.6 8.2 11.5

Min. Dynamic Pressure Primary

Supply

4.2 7.4 10.3

Max. Static Pressure ERM 4.0 7.2 10.0

Min. Dynamic Pressure ERM 3.5 6.5 9.0

Note - Table 4 shows typical examples. These

gures may dier depending on the hospital’s

pipeline management policy.

CAUTION: It would be recommended to

set the ERM line pressure at least 0.2 bar below

the main supply source pressure at full design

owtoensuretheemergencymanifolddoes

not supply the pipeline during normal primary

source operation.

The recommended setup of the ERM is to have the

left hand bank open and ready to come online and

the right hand bank closed.

In the event of the primary system failing to

supply (Awareness of the Primary supply failure is

typically from central alarm system) the ERM line

regulator (see gure 1) can be manually increased

to match the primary supply’s nominal values, so

that the full distribution pressure is restored.

regulators is a none relieving type. Always leave

valve ‘C’ closed when nished.

3.3.3 Check that the line pressure does not vary

outside of the requirements of the installation

(see table 4, Section 4 - Principle of Operating, for

typical values).

3.3.4 Complete the steps in section 4.2 -

Procedure to prime ERM, to bring the ERM online.

Loading...

Loading...