20

Emergency Reserve Manifold

2005715.05

6.0 Component Replacement

Procedures

WARNING: IT IS ESSENTIAL THAT ONLY

GENUINE BEACONMEDÆS SPARE PARTS ARE

FITTED DURING MAINTENANCE.

CAUTION: Ensure no contaminates, oil

or grease come into contact with any of the gas

connection/internals.

Preparation For Component Re-

placement

6.0.1 Ensure the main gas supply system is

functioning correctly and supplying the pipeline.

6.0.2 Close the ERM line isolation valve ‘B’ (See

gure 1). Close all the cylinder and open both

bank valves (see gure 1 and 2).

5.3.9 Open Valve ‘C’ and carefully bleed gas from

the sampling outlet.

5.3.10 Observe the falling pressure on the contact

gauge.

5.3.11 When the pressure falls to 14 bar for 100

bar scale, and 68 bar for the 315 scale gauges the

contact will provide an open signal, initiating a

“Reserve Low” alarm on the primary alarm system.

Should this not occur replace the contact gauge

(See section 6.10).

5.3.12 Repeat steps 5.3.8 to 5.3.11 for the

opposite contact gauge. Close valve ‘C’ when

nished.

5.3.13 Finally, tighten all joints, open all cylinder

valves and perform a leak test on all joints.

5.3.18 Perform the steps in section 4.2 -

Procedure to prime ERM.

5.3.19 The ERM is now ready for use.

5.4 5 Years

Replace the pressure safety valve for a new

certied relief valve, see sections 6.4 & 6.5.

5.5 As Required

Replace tailpipes, pressure safety valve, pressure

regulator, high-pressure isolation valve, isolation

valves, contact gauges, non-return valve etc. as

and when required (see section 6.0 to 6.10).

6.0.3 Open the sampling outlet valve ‘C’, and

probe the outlet to depressurise the system.

CAUTION:Whenexhaustinganaesthetic

andoxygenmanifoldsensurethatthemanifold

room is well ventilated and no potential ignition

sources are present.

Note - If the cylinder contents gauges are not

rapidly dropping in pressure, stop draining the

system and check all cylinders are correctly

isolated.

6.1 Replace line non-return valve

(P/N: 2005778)

6.1.1 Complete steps in section 6.1 before

carrying out any component replacement on the

ERM.

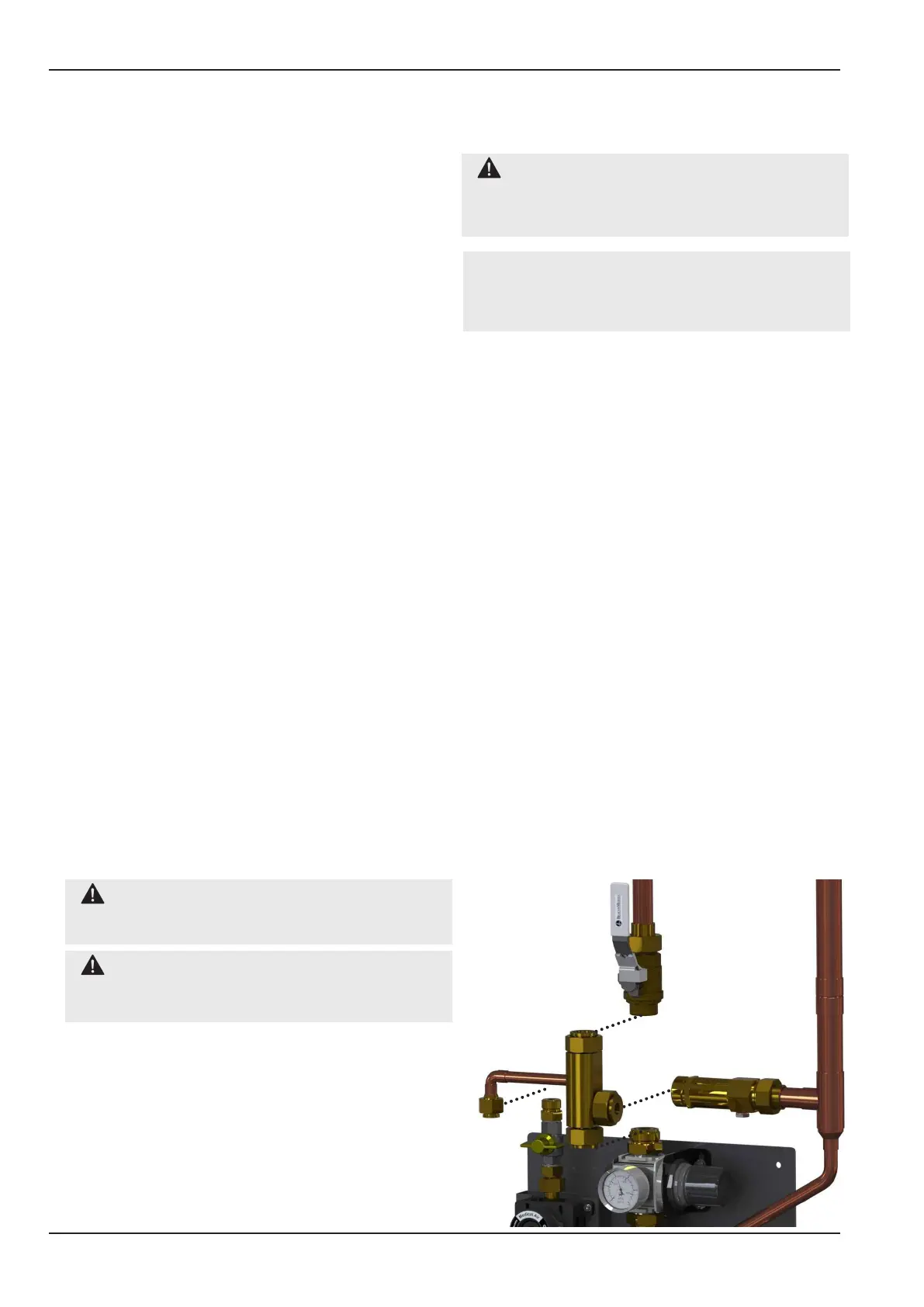

6.1.2 Slowly turn the swivel nut of the top 1”

connection. If the you hear gas escaping do not

fully unscrew the joint until the system is fully

drained.

6.1.3 Fully disconnect all 4 joints as shown in

gure 16 and gently remove the unit by sliding it

towards you. Take care not to damage the seals.

6.1.4 Inspect the existing seals and replace if

required, see gure 16 for seal part numbers.

6.1.5 Taking care not to damage the O-ring seals

replace the new non-return valve as shown in

gure 16, and fasten the 4 at face joints.

6.1.6 Follow steps in section 6.11 bring the ERM

back online.

Figure 16 - Line Non-return Valve Replacement

3 x 1” at face

connections with swivel

nut and O-ring seal

(Seal P/N: 2000152)

1 x 1/2” at face

connection with swivel

nut and O-ring seal (Seal

P/N: 1823637)

Loading...

Loading...