Beijer Electronics Frequency Inverter BFI-E3 KI00369B 2019-09

www.beijer.se www.beijer.no www.beijer.dk www.beijerelectronics.de www.beijerelectronics.com www.beijerelektronik.com.tr 16 (24)

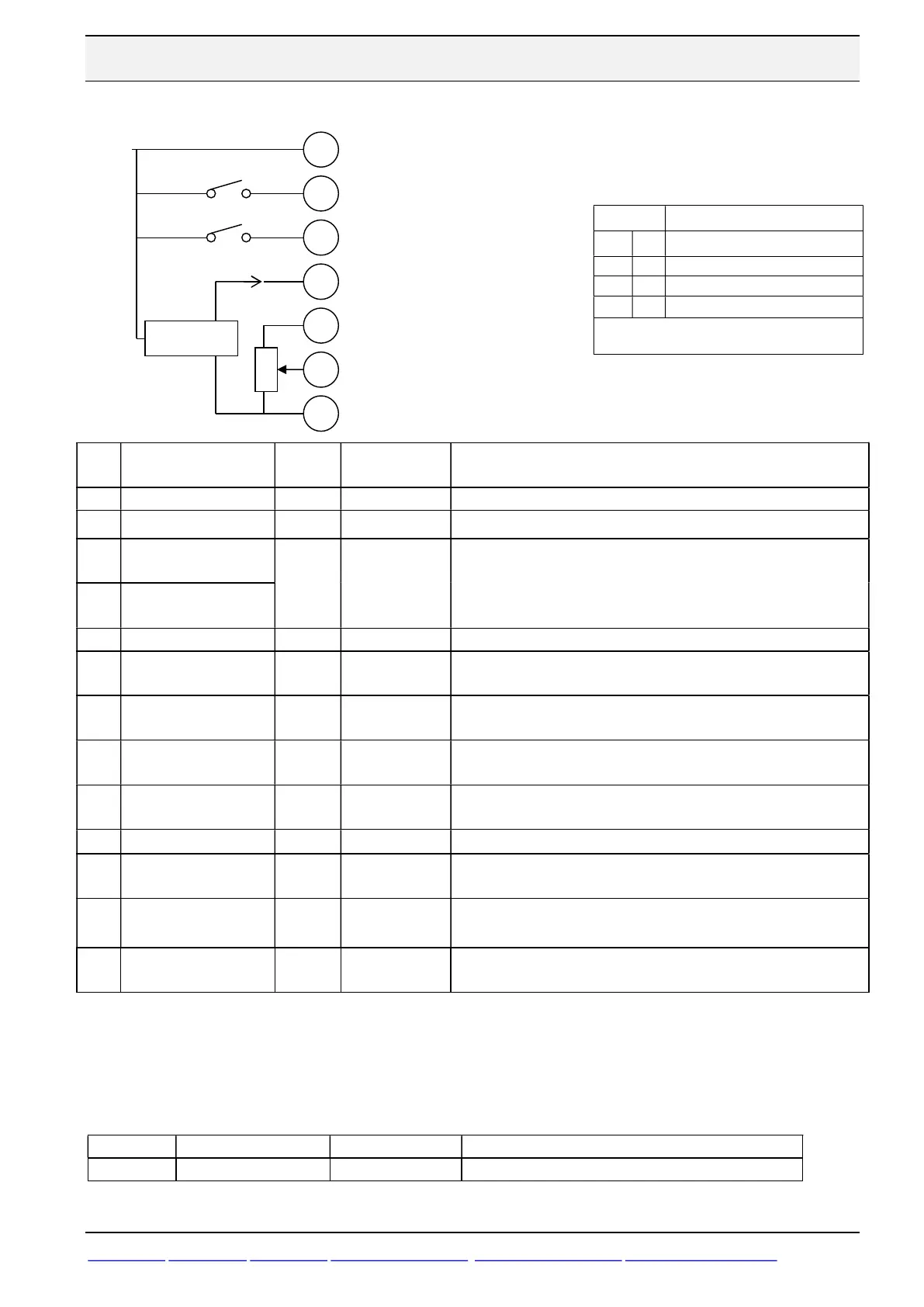

5.16 PI-control

Para-

Name Default

Recommended

Function

P-12

Command Source 0 5

5: PI-control with external feedback signal.

P-15 Input Selection 0 0

0 = PI-feedback Terminal 4. PI or Preset speed Terminal 3.

P-16

Analog Input Format ,

terminal 4

U 0-

U 0-10 = 0 to 10 VDC.

A 0-20 = 0 to 20mA.

t 4-20 4 to 20mA. Trip if signal level < 3mA.

r 4-20 4 to 20mA. Preset Speed 1 if signal level < 3mA.

P-47

2nd Analog Input

Format , terminal 6

P-20 Preset Speed 1 0 Can be set between 0 to P-02 setting ( Maximum speed)

P-41

PI Controller

Proportional Gain

1,0

PI Proportional Gain. Higher values provide a greater change in

the drive output frequency. Too high value cause instability.

P-42

PI Controller Integral

Time

1,0

PI Integral Time.

Larger values provide a more damped response

for systems where the overall process responds slowly.

P-43

PI Controller

Operating Mode

0

0 : Increased motor speed gives increased feedback signal.

1 : Increased motor speed gives decreased feedback signal.

P-44 PI Digital Setpoint 0

0 : Digital Preset PI-Setpoint in P-45.

1 : Analog Input 1, Terminal 6 PI-setpoint.

P-45 PI Digital Setpoint 0,0

When P-44 = 0, PI-setpoint for PI-Controller.

P-46

PI Feedback Source

Select

0 0

0 : Analog Input 2 (Terminal 4), 1 : Analog Input 1 (Terminal 6).

2 : Motor Current.

P-48 Standby mode Timer 0 sec

0: Function off

Time to run with mimimal speed , P-02, until PI-controller enter

Sleep mode and motor stops.

P-49

Retention

5,0 %

Level off error between PI-controllers setpoint and feedback

signal when motorn is to restart.

5.17 Energy Optimization function

The Energy Optimization function is designed to maximize the energy savings achievable when

the motor and drive is not operating at its rated load. Function works best at constant speed, as

the motor voltage is reduced, the slip of the motor may increase, resulting in a small drop in

motor speed, which can make the PI control unstable.

P-06 Energy Optimization 0 0 = Disbaled 1 = Enabled

Status

Action

DI1

DI2

P12=5 & P15 = 0

0 any

No output from drive

1 0

Run with PI-control

1 1

Run with PreSpeed in P-20

P-44=0 : Set point in P-45

DI1: Start signal

DI2: PI / Pre Speed 1

PI-feedback

+24 VDC

PI-setpoint

+10 VDC

0 VDC

Sensor

Loading...

Loading...